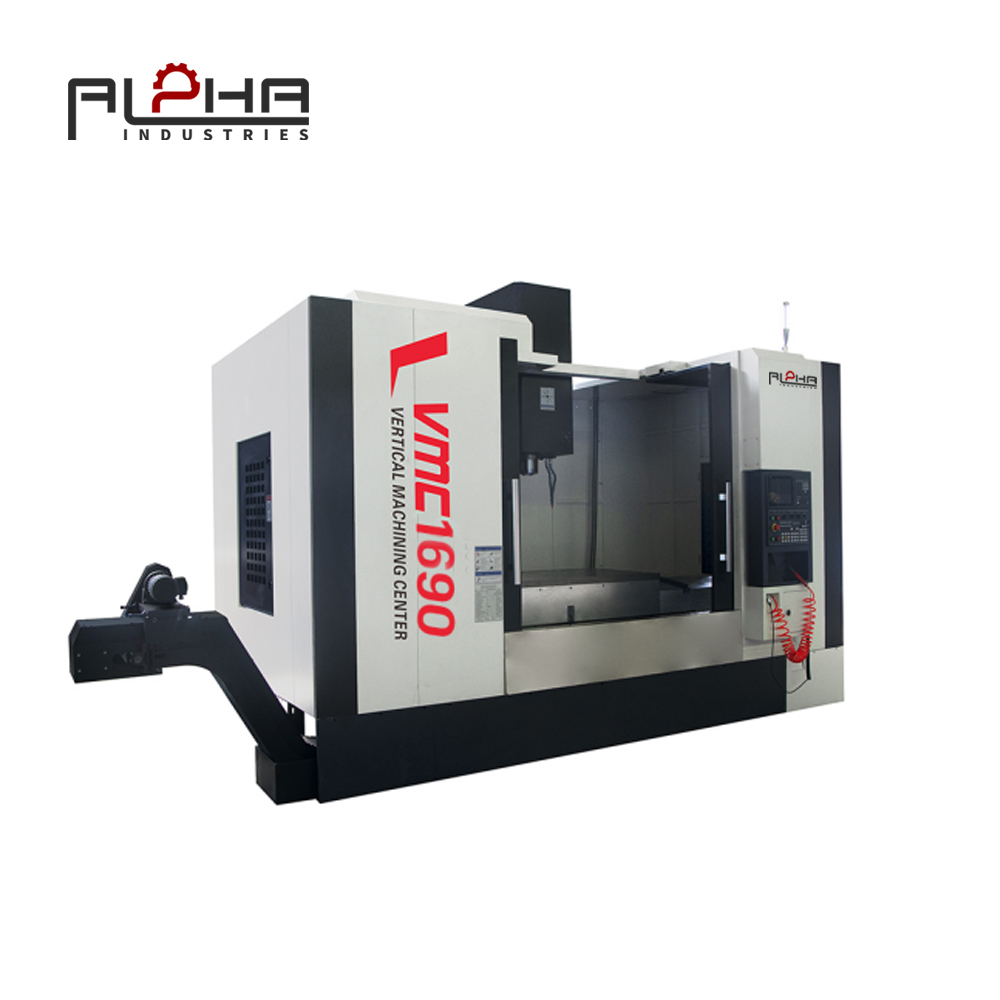

Vertical Machine Center in Aerospace Manufacturing

In aerospace production, dimensional accuracy and surface integrity are paramount. A Vertical Machine Center (VMC) is essential for producing turbine blades, engine housings, and structural airframe components. With multi-axis capability and micron-level tolerance control, VMCs meet strict aerospace standards while ensuring process stability during extended machining cycles.

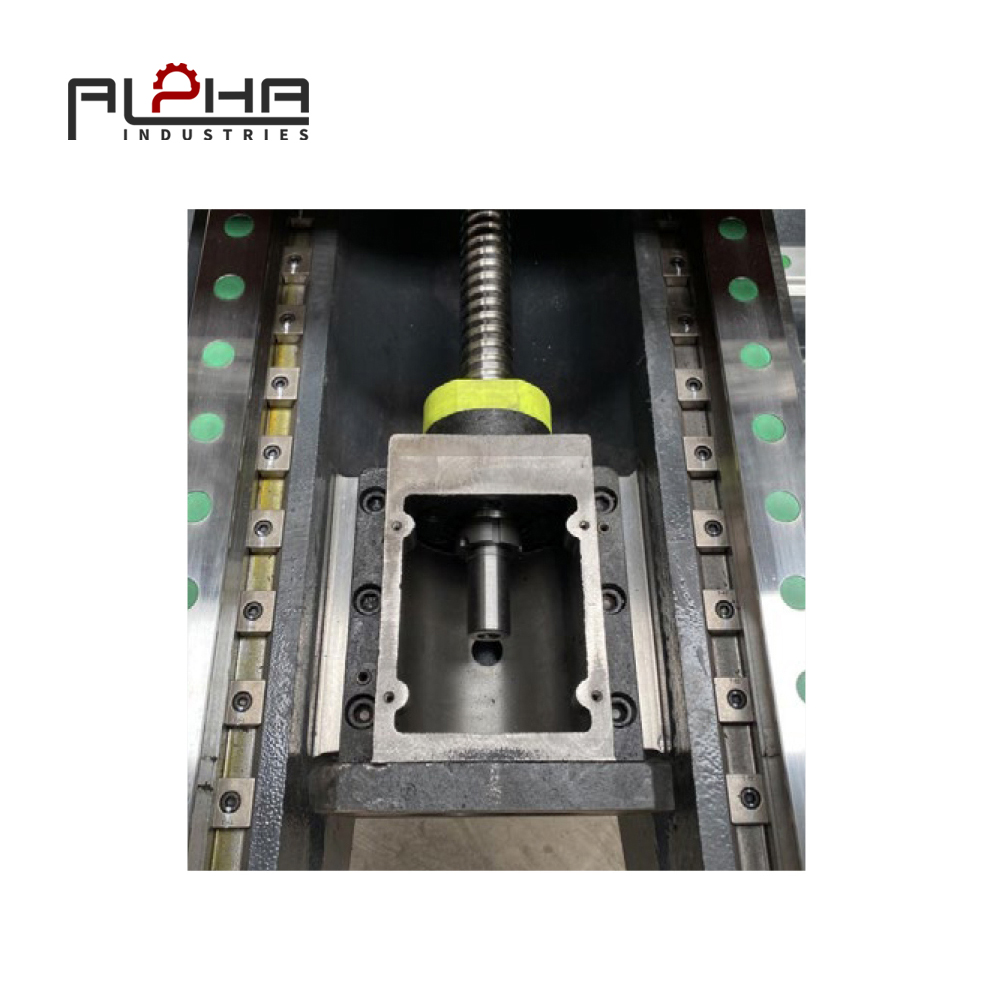

High-Rigidity Structure for Aerospace Precision

The aerospace industry requires machining of titanium alloys, Inconel, and hardened steels, all known for their toughness. VMCs feature reinforced cast-iron frames, cross-ribbed bed structures, and pre-tensioned ball screws, which suppress vibration and ensure consistent tool engagement. This rigidity directly impacts the fatigue resistance and reliability of aerospace parts.

Spindle Technology and Aerospace Surface Quality

Aerospace components often demand mirror-like surface finishes for aerodynamic efficiency. The high-speed vertical spindle in a VMC uses ceramic bearings and adaptive thermal compensation, ensuring constant accuracy under heavy-duty cutting. Variable spindle torque modes allow smooth transitions between high-speed finishing of thin walls and heavy-duty roughing of engine casings.

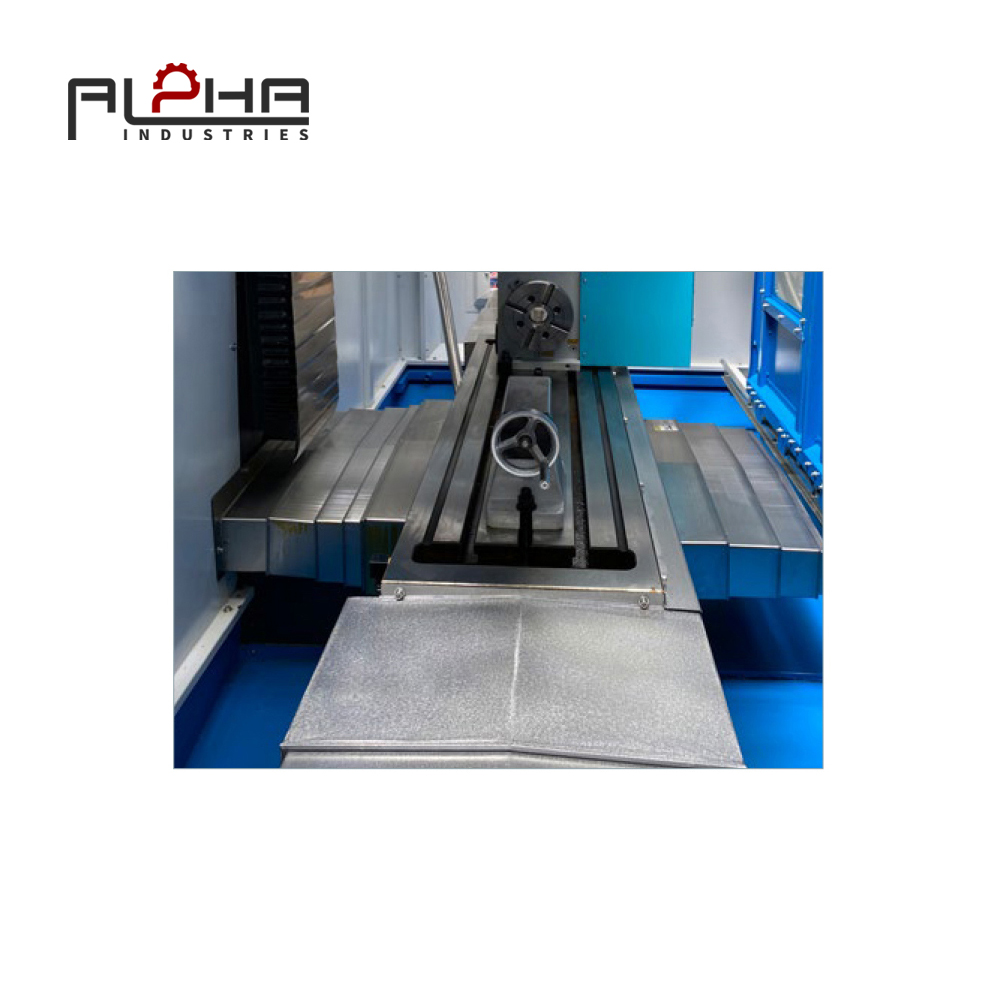

Multi-Axis Capability in Aerospace Machining

Complex aerospace parts require machining along multiple planes. Advanced VMCs integrate 4th and 5th-axis rotary tables, enabling simultaneous machining of intricate geometries such as turbine blade profiles. This reduces the need for multiple setups, lowers cumulative error, and significantly improves throughput.

Tool Management for Aerospace Applications

Aerospace machining often involves long tool paths and diverse cutting tools. VMCs are equipped with large-capacity Automatic Tool Changers (ATC), sometimes exceeding 60 tools, combined with tool breakage detection and wear monitoring. This ensures uninterrupted machining of large aerospace components with minimal operator intervention.

Cooling Systems for Heat-Resistant Alloys

Machining aerospace-grade alloys generates extreme heat. VMCs employ high-pressure coolant delivery, through-spindle coolant, and air-blast systems to maintain cutting efficiency and prevent thermal cracking of tools. Integrated coolant filtration systems ensure continuous clean coolant circulation, extending tool and spindle life.

Aerospace Quality Control with VMCs

Modern VMCs integrate on-machine probing and laser measurement systems, ensuring that every aerospace component is inspected during production. This in-process verification reduces reliance on external measuring equipment and guarantees compliance with aerospace tolerance standards, such as AS9100.

FAQ – People Also Ask

1. Why are Vertical Machine Centers essential in aerospace machining?

VMCs provide the rigidity, precision, and automation required to machine aerospace alloys and maintain tolerances critical for safety and performance.

2. Can Vertical Machine Centers handle titanium and Inconel?

Yes, VMCs with high-torque spindles and rigid construction can machine titanium and Inconel efficiently while maintaining surface integrity.

3. How do VMCs ensure repeatability in aerospace components?

By using linear guideways, thermal compensation, and probing systems, VMCs ensure consistent part accuracy across repeated production cycles.

4. What role does multi-axis machining play in aerospace?

Multi-axis capability enables machining of complex geometries such as turbine blades in a single setup, reducing error accumulation.

5. How do Vertical Machine Centers improve efficiency in aerospace production?

With ATC systems, high-pressure coolant, and in-process probing, VMCs minimize downtime, reduce rework, and achieve faster delivery of aerospace parts.