What is a VMC (Vertical Machining Center)?

A VMC (Vertical Machining Center) is a highly automated metal cutting machine that performs milling, drilling, tapping, and boring with vertical spindle orientation.

The spindle axis is vertically aligned, allowing tools to move precisely along X, Y, and Z axes for multi-surface machining.

Equipped with a CNC control system, a VMC can automatically execute complex machining programs with high repeatability and accuracy — making it a core machine in automotive, aerospace, mold, and precision parts industries.

Working Principle of VMC

A Vertical Machining Center operates based on computer numerical control, which directs the spindle and table movement during cutting operations.

Step-by-Step Process:

-

Programming – The operator inputs or uploads a G-code machining program.

-

Tool Selection – The automatic tool changer (ATC) selects the correct cutting tool.

-

Positioning – The servo motor moves the worktable to the defined coordinates.

-

Machining – The spindle rotates at high speed to cut, drill, or mill the material.

-

Finishing – The part is machined with high precision, ensuring surface smoothness and dimensional accuracy.

This intelligent process enables stable, continuous, and precise machining suitable for both mass production and complex part fabrication.

Key Features of VMC

1) High-Performance CNC System

Equipped with controllers such as Fanuc, Siemens, or Mitsubishi, ensuring fast response, smooth interpolation, and reliable operation.

2) Automatic Tool Changer (ATC)

Allows quick tool replacement within seconds, reducing downtime and enhancing efficiency.

3) Precision Spindle

High-speed spindle with ceramic bearings ensures excellent rigidity and surface finish.

Spindle speeds range from 6,000 to 15,000 RPM, suitable for both rough and fine machining.

4) Linear Guideways & Ball Screws

High-precision linear guideways and C3-grade ball screws deliver smooth motion, low vibration, and high positioning accuracy.

5) Rigid Machine Structure

The machine frame is made from Meehanite cast iron, designed with finite element analysis (FEA) to reduce deformation under heavy loads.

6) Coolant & Chip Removal System

Efficient coolant circulation and chip conveyor ensure thermal stability and clean machining environment.

Advantages of Using a VMC

-

High Accuracy: Maintains ±0.005 mm positioning precision.

-

Automation Ready: ATC and CNC control enable continuous operation.

-

Versatile Machining: Performs milling, drilling, tapping, and boring in one setup.

-

Stable Performance: Heavy-duty frame and dynamic balancing reduce vibration.

-

Cost Efficiency: Faster cycle time and reduced rework lower production cost.

Applications of VMC

VMCs are widely used in high-precision manufacturing industries, including:

-

Automotive Components – Engine parts, molds, and transmission housings.

-

Aerospace Industry – Structural components and precision fixtures.

-

Electronics – Heat sinks, enclosures, and aluminum casings.

-

Tool & Die Industry – Mold bases and cavity machining.

-

General Engineering – Custom metal and plastic components.

Each application benefits from the precision, repeatability, and automation of modern vertical machining centers.

Maintenance and Operation Tips

-

Check spindle bearings and tool holders regularly for runout.

-

Keep the coolant clean and maintain the filtration system.

-

Lubricate linear guides and ball screws periodically.

-

Inspect ATC mechanism for tool clamping reliability.

-

Follow calibration and safety inspection schedules to ensure long-term accuracy.

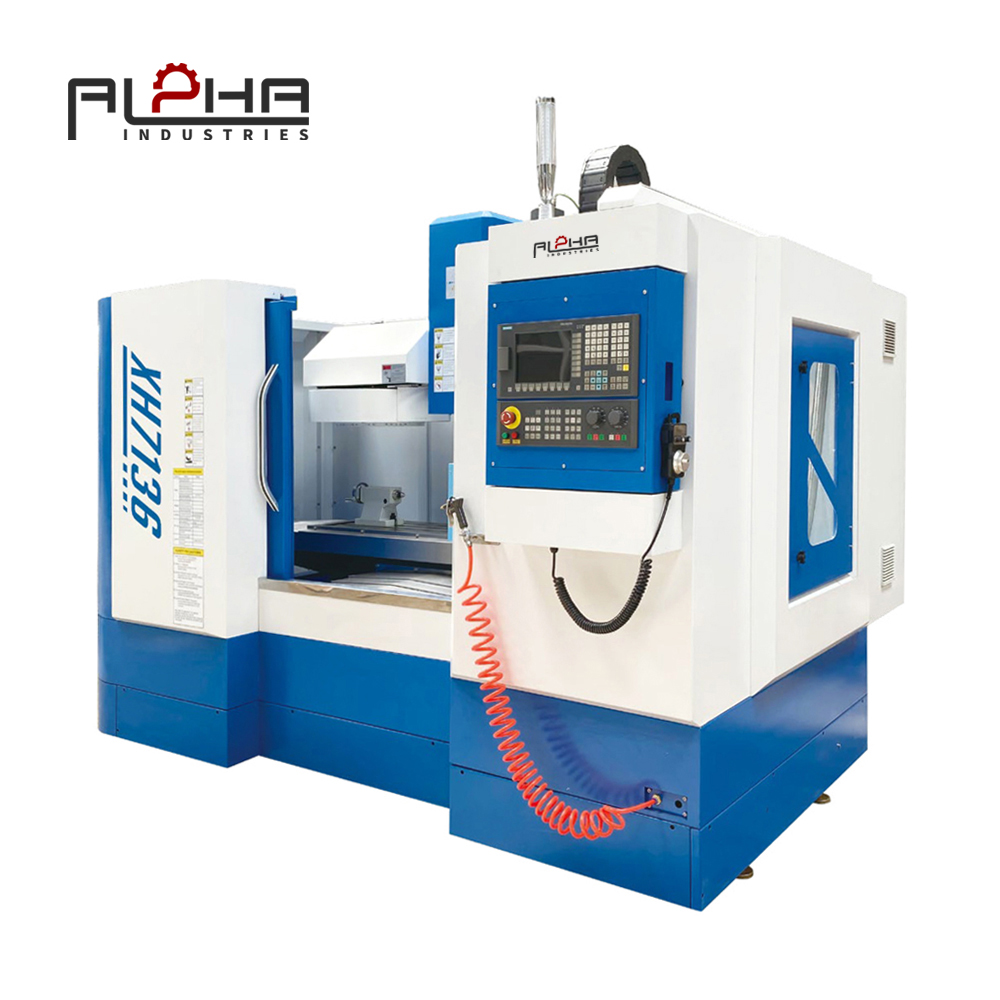

Why Choose a VMC from Alpha

At Alpha, we design and manufacture high-precision Vertical Machining Centers (VMCs) that combine innovation, stability, and efficiency.

Our VMCs feature:

-

International CNC systems (Fanuc / Siemens / Mitsubishi)

-

High-speed, high-torque spindle design

-

Automatic chip removal and coolant management

-

Heavy-duty cast iron structure with thermal balance design

-

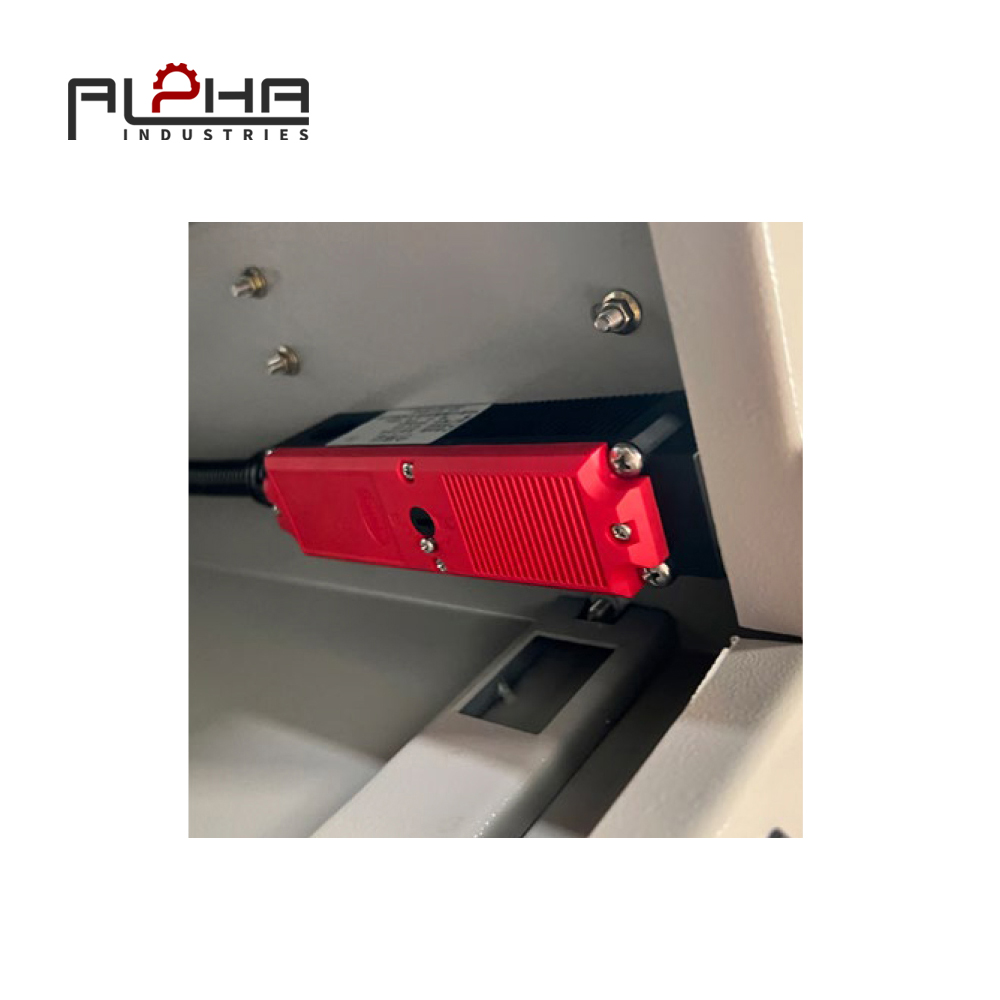

Full CE-compliant safety protection

Alpha provides customized VMC solutions to meet the demands of precision machining, mold manufacturing, and high-volume production — ensuring every machine delivers accuracy, reliability, and productivity.

FAQ About VMC (Vertical Machining Center)

Q1: What is the main difference between a VMC and a CNC Milling Machine?

A VMC is a type of CNC milling machine with a vertically oriented spindle, offering higher automation and tool-changing capability.

Q2: What materials can a VMC process?

VMCs can machine steel, aluminum, copper, brass, plastics, and titanium alloys.

Q3: What is the accuracy of a typical VMC?

Modern VMCs can achieve positioning accuracy of ±0.005 mm and repeatability within ±0.003 mm.

Q4: How many axes does a VMC have?

Standard VMCs are 3-axis, while advanced models support 4-axis or 5-axis for complex machining.

Q5: How to select the right VMC?

Choose based on workpiece size, material hardness, spindle speed, tool capacity, and production volume.

Call to Action

Looking for a reliable Vertical Machining Center (VMC) for your production line?

Contact Alpha today for a customized VMC solution and professional quotation.