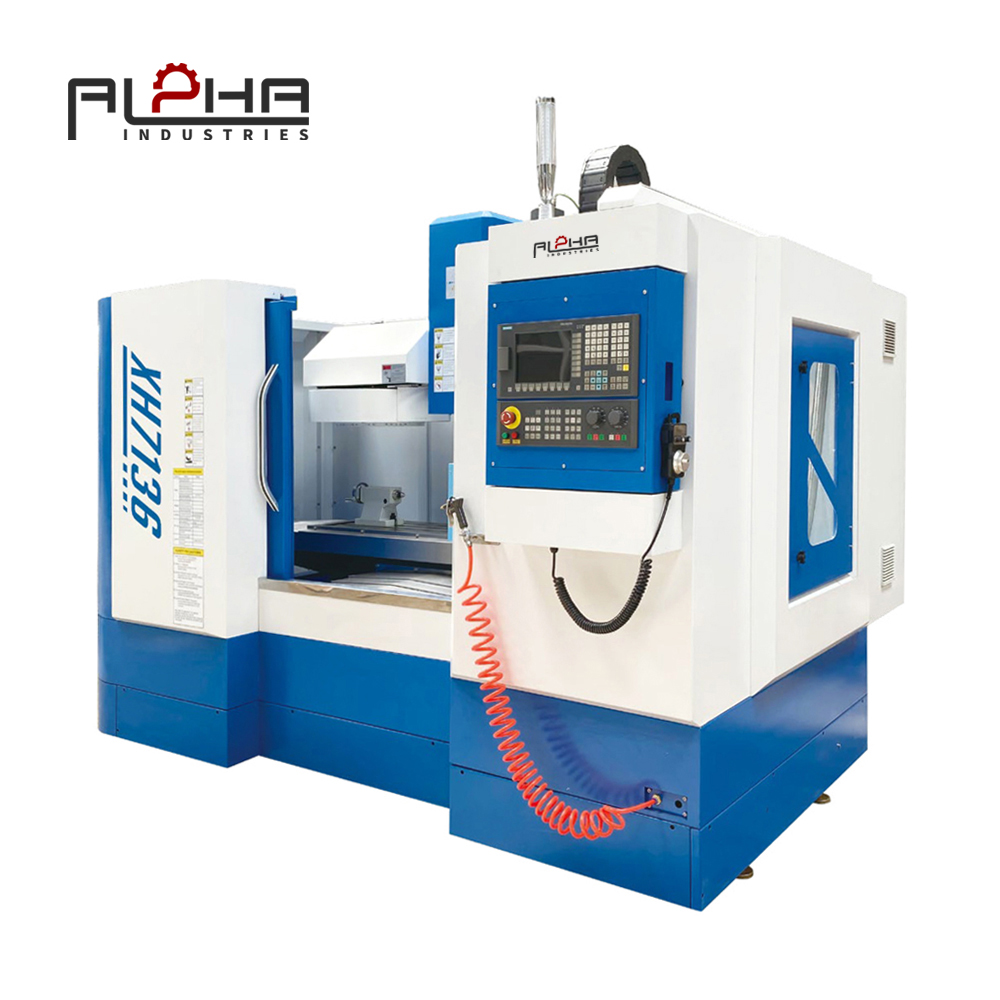

What is a Vertical Machining Center (VMC)?

A Vertical Machining Center (VMC) is a computer-controlled milling machine designed for high-precision metal cutting and drilling operations. It features a vertically oriented spindle, allowing tools to move along the X, Y, and Z axes to perform complex milling, boring, tapping, and engraving tasks.

At Alpha, our VMCs combine high-speed spindles, servo-driven axes, and rigid structural design to meet the demands of modern industries, from aerospace to precision mold manufacturing.

Why the Spindle Defines Precision

The spindle is the beating heart of every VMC — the key element determining cutting accuracy, surface quality, and tool life. Alpha’s spindle design integrates advanced high-speed bearing systems, thermal compensation technology, and dynamic balance calibration to achieve exceptional performance stability.

Our engineering philosophy centers on one principle: precision begins at the spindle.

High-Speed Spindle Design

Modern machining requires both speed and stability. Alpha’s direct-drive spindle technology eliminates belt slippage and vibration, ensuring smoother torque transmission.

Key Features:

-

Maximum Speed: up to 15,000 rpm for high-speed finishing.

-

Dynamic Balancing: ISO G2.5 precision ensures low vibration and minimal runout.

-

Lubrication System: Air-oil lubrication for longer bearing life.

-

Cooling System: Integrated spindle chiller maintains temperature within ±0.5°C.

This combination enables consistent machining accuracy, even in long production cycles.

Thermal Stability — Maintaining Accuracy Over Time

Heat generation is a major challenge during high-speed machining. Alpha VMCs employ intelligent thermal compensation algorithms and coolant circulation systems that stabilize the spindle and machine frame.

This ensures:

-

Dimensional accuracy even under continuous operation.

-

Extended tool life through controlled temperature balance.

-

Reduced deformation of spindle and column under heavy load.

In industries like mold processing or aerospace component manufacturing, where tolerances are measured in microns, this stability defines excellence.

Spindle Power and Torque Control

Different materials require different torque profiles. Alpha’s spindle motor delivers both high torque at low speed for heavy-duty cutting and stable acceleration at high speed for finishing.

Our proprietary vector control technology provides:

-

Smooth torque curve transition for stable cutting force.

-

Energy-efficient output, reducing power consumption.

-

Optimized acceleration/deceleration for cycle time reduction.

These innovations empower Alpha VMCs to handle materials from stainless steel to aluminum alloys with exceptional adaptability.

Machine Structure and Vibration Damping

The performance of a VMC spindle relies on its foundation. Alpha adopts a finite-element optimized column and base structure, using high-rigidity cast iron and vibration-absorbing ribs to minimize resonance.

This structure:

-

Reduces chatter during high-speed cutting.

-

Ensures stability under heavy tool loads.

-

Increases long-term machine accuracy and lifespan.

Combined with linear guideways and preloaded ball screws, the machine maintains positioning accuracy within ±0.005 mm.

CNC System Integration

Alpha integrates leading CNC control systems (Fanuc, Siemens, or GSK) with full spindle control feedback. The real-time communication between the CNC unit and the spindle encoder ensures responsive cutting speed adjustments for precision machining.

The interface supports:

-

3D toolpath visualization

-

Automatic spindle warm-up routines

-

Adaptive cutting feed control

-

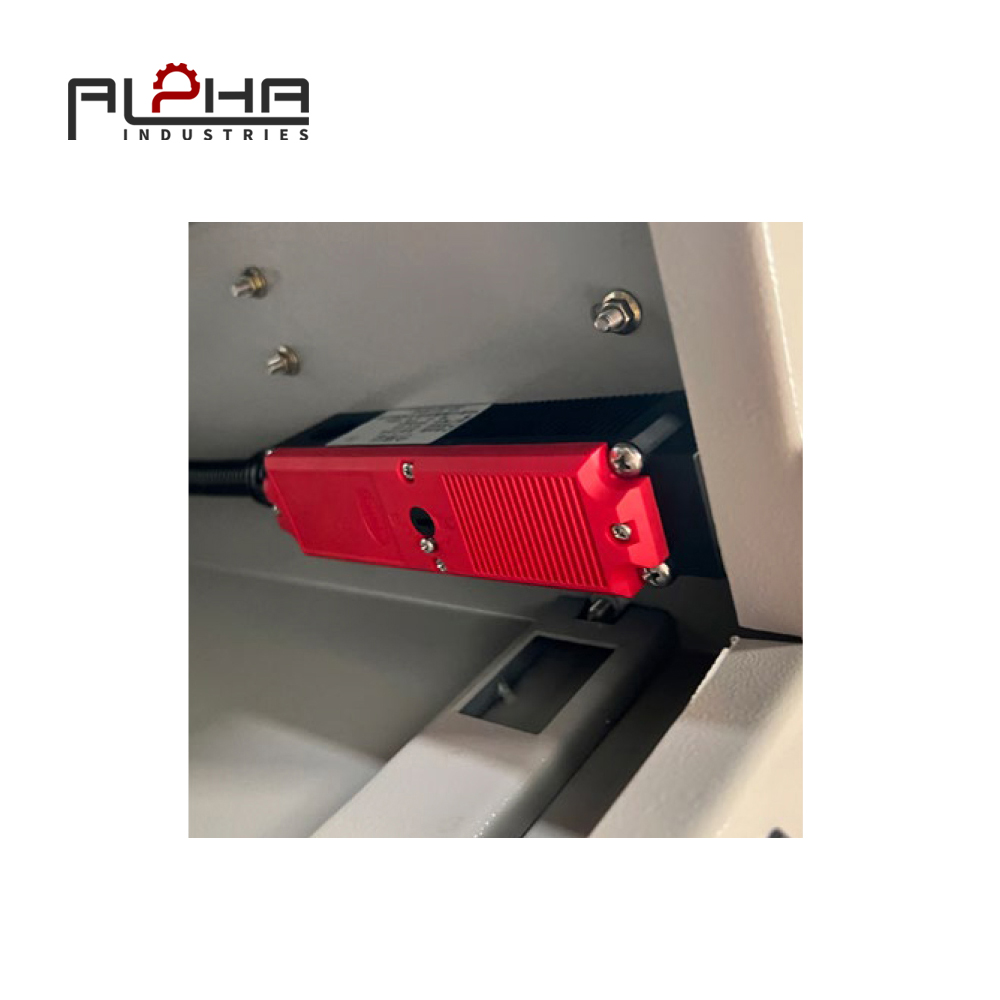

Spindle vibration monitoring

These smart features make Alpha’s VMC ideal for smart factories and Industry 4.0 production lines.

Multi-Industry Applications

Alpha’s VMCs are engineered for versatility, serving diverse manufacturing needs:

-

Aerospace: precision aluminum structure components.

-

Automotive: engine parts, transmission housings, brackets.

-

Mold making: die cavities, electrodes, precision tooling.

-

Electronics: heat sinks, mobile frame housings.

-

Medical devices: implants, surgical instruments.

Each application benefits from spindle reliability, thermal control, and repeatable cutting accuracy.

Energy Efficiency and Sustainability

Alpha integrates servo-hydraulic drive and energy-regenerative braking systems to reduce power loss during spindle acceleration and deceleration. Combined with optimized lubrication, the system achieves up to 30% energy savings compared to conventional VMCs.

This commitment to sustainability supports global goals for low-carbon manufacturing while maintaining high productivity.

Technical Specifications of Alpha VMC

| Parameter | Specification |

|---|---|

| Spindle Speed | 8,000 – 15,000 rpm |

| Spindle Taper | BT40 / HSK-A63 |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Spindle Cooling | Chiller Controlled |

| Axis Drive System | Servo Motor |

| Structure Material | High-Rigidity Cast Iron |

| Control System | Fanuc / Siemens / GSK |

FAQ

Q1: What makes the spindle the most important part of a VMC?

The spindle determines cutting accuracy, surface quality, and machining speed. Its design affects both performance stability and production efficiency.

Q2: How does spindle cooling improve machining accuracy?

Cooling systems control spindle temperature, preventing expansion and ensuring consistent tool positioning for precision machining.

Q3: What industries benefit most from Alpha’s VMC?

Automotive, aerospace, mold, and electronics industries rely on Alpha’s VMC for high-speed, high-accuracy machining applications.

Q4: What is the accuracy level of Alpha’s VMC?

Alpha’s vertical machining centers achieve positioning accuracy within ±0.005 mm and repeatability within ±0.003 mm.

Call to Action (CTA)

Empower your production with Alpha’s precision Vertical Machining Centers.

Experience superior spindle technology and machining accuracy built for modern industries.

Explore Alpha VMC Machines

Learn More About Metal Processing Solutions