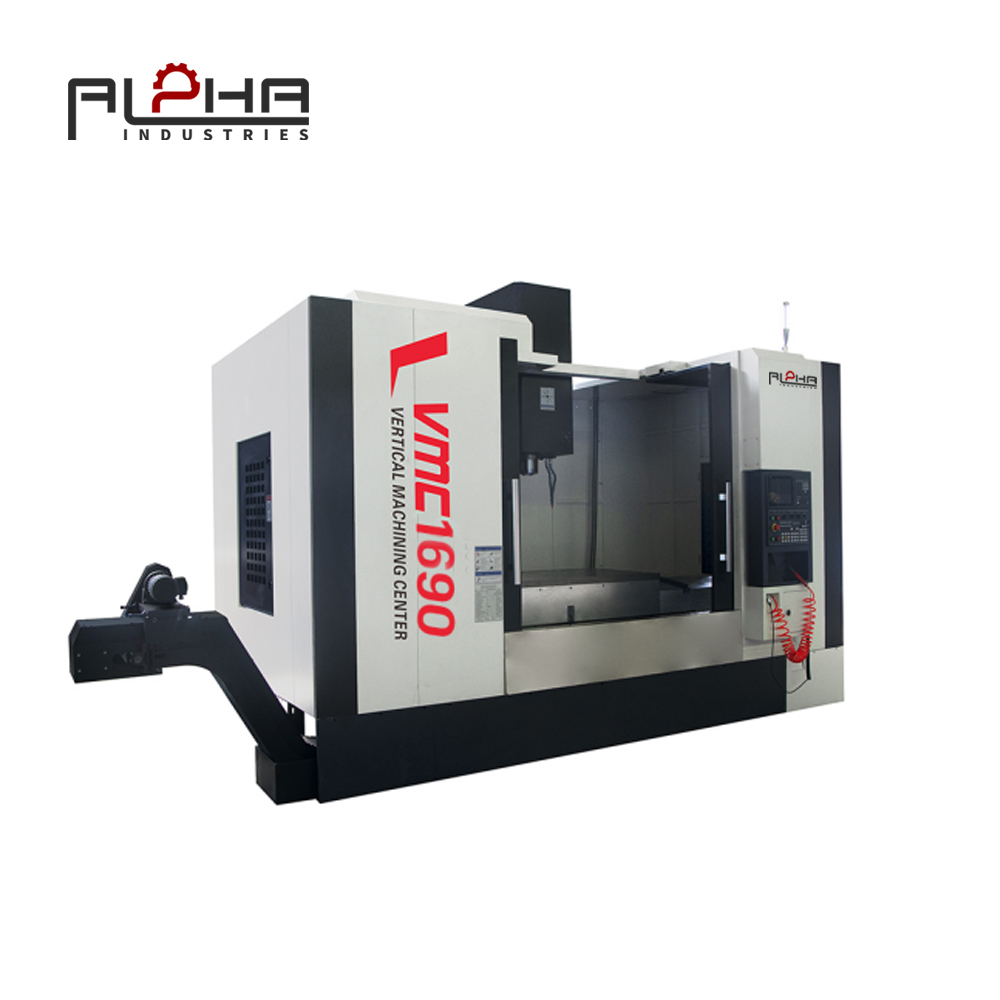

Vertical Machine Center in Mold Manufacturing

A Vertical Machine Center (VMC) plays a decisive role in mold manufacturing, where micron-level accuracy, repeatability, and surface finish are critical. Unlike general-purpose milling, mold machining demands extended spindle runout precision, high-rigidity construction, and advanced cooling systems to prevent thermal distortion during long machining cycles.

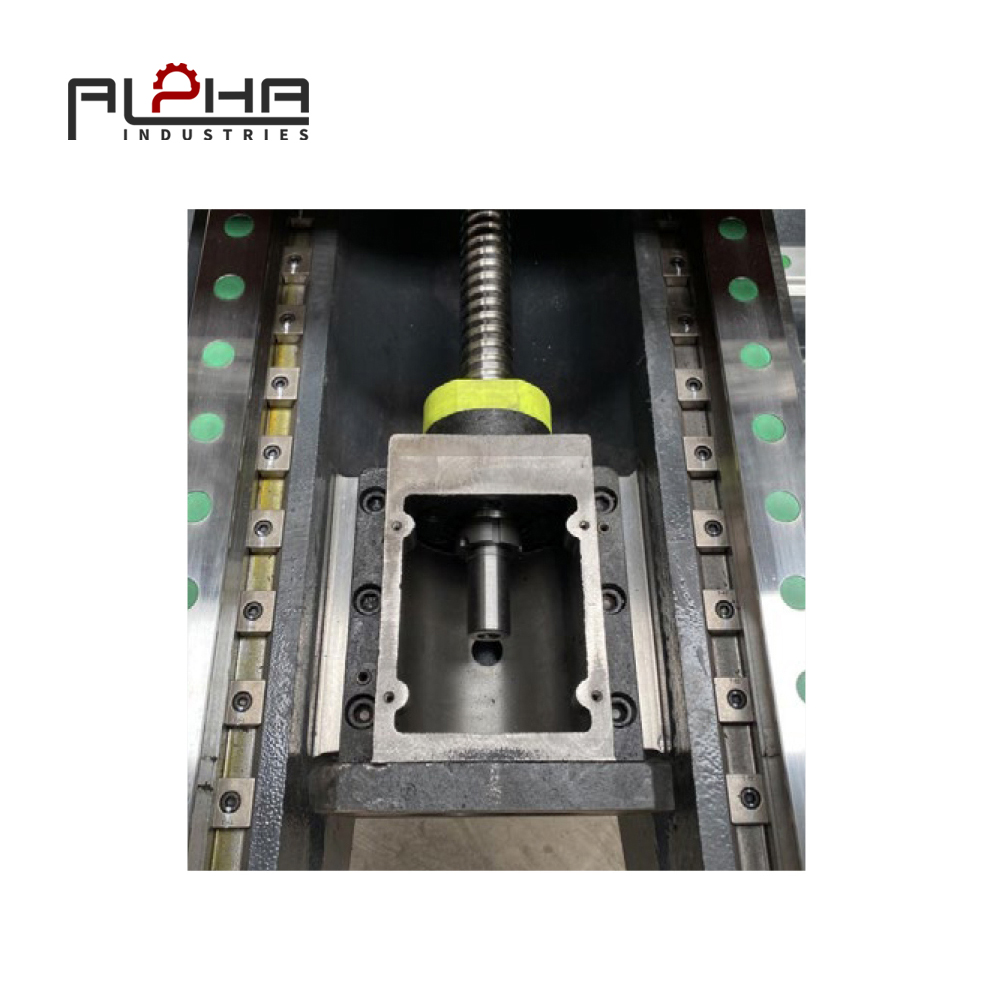

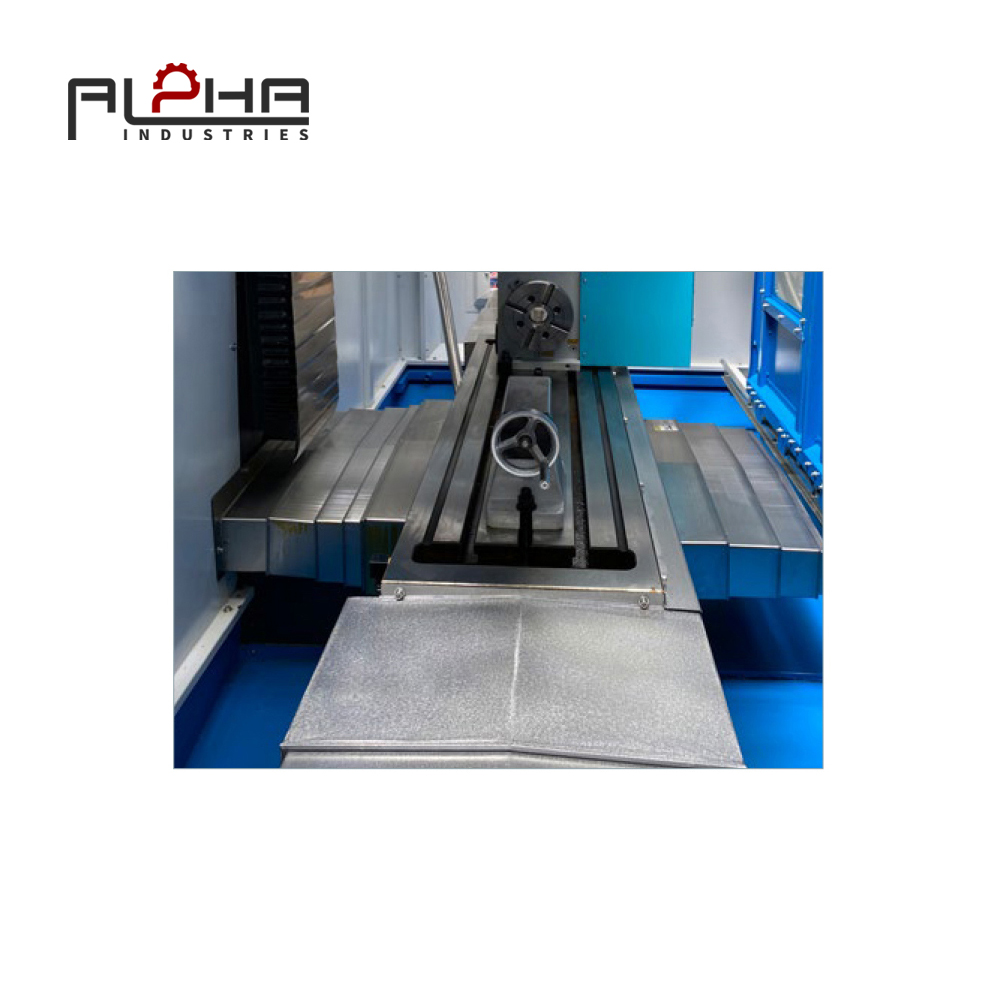

Structural Advantages of Vertical Machine Center

The cast iron bed and column structure of a VMC minimizes vibration and ensures dimensional stability. In mold manufacturing, even minor vibrations can cause tool marks or misalignments, making rigidity a non-negotiable requirement. Linear guideways and precision ball screws further guarantee smooth axis movement with minimal backlash, directly enhancing cavity accuracy.

Spindle Performance and Surface Finish

The high-speed vertical spindle allows for rapid tool engagement and superior chip evacuation in mold cavity machining. Advanced spindle bearings and thermal compensation systems ensure consistent surface finish across complex geometries. For hardened tool steels commonly used in mold production, the spindle’s torque stability enables uninterrupted roughing and finishing within the same setup.

Automation and Tool Management in VMC

Mold manufacturing often requires a series of cutting tools ranging from roughing end mills to fine ball nose cutters. The Automatic Tool Changer (ATC) in a Vertical Machine Center ensures uninterrupted operation by reducing downtime between tool changes. Combined with tool life management software, the system tracks wear, automatically swapping tools when needed, which is critical for long-cycle mold operations.

Cooling and Thermal Stability

Thermal distortion is a major challenge in mold machining. Advanced VMCs integrate coolant-through-spindle systems, chiller units, and air-oil lubrication to maintain temperature stability. This minimizes dimensional deviations, ensuring that complex molds meet tolerances without requiring excessive rework.

Precision in Mold Cavity and Core Machining

VMCs equipped with multi-axis capability and probing systems enable highly accurate cavity and core machining. In-process probing ensures real-time dimensional verification, reducing scrap rates. High-speed look-ahead CNC controls maintain smooth tool paths, preventing tool chatter and extending tool life in deep cavity cutting.

Multi-Industry Applications Beyond Mold Manufacturing

While mold and die are core sectors, VMC technology extends to aerospace turbine components, medical implants, and precision automotive parts. The adaptability of tool changers, spindle speed ranges, and rigid construction makes VMCs essential wherever tight tolerances and complex geometries are required.

FAQs:

1. How does a Vertical Machine Center reduce errors in mold manufacturing?

A VMC reduces errors by integrating thermal compensation, in-process probing, and backlash-free ball screws. This ensures precise cavity depth, consistent surface finish, and minimal manual correction.

2. What is the role of spindle cooling in a Vertical Machine Center?

Spindle cooling maintains thermal stability, preventing expansion that could alter machining accuracy. This is especially critical in long machining cycles for mold cavities.

3. Can a Vertical Machine Center handle hardened steel for molds?

Yes, high-rigidity VMCs with torque-stable spindles and carbide tooling are capable of roughing and finishing hardened tool steels, reducing the need for separate EDM operations.

4. How does tool life management improve mold machining efficiency?

Tool life management tracks cutting tool wear and automatically switches tools when limits are reached. This prevents tool breakage, reduces downtime, and maintains consistent mold quality.

5. Why is a Vertical Machine Center preferred over horizontal machining for molds?

VMCs provide superior chip evacuation in deep cavities, simpler fixturing, and higher accessibility for multi-axis operations, making them more efficient for mold machining compared to horizontal setups.