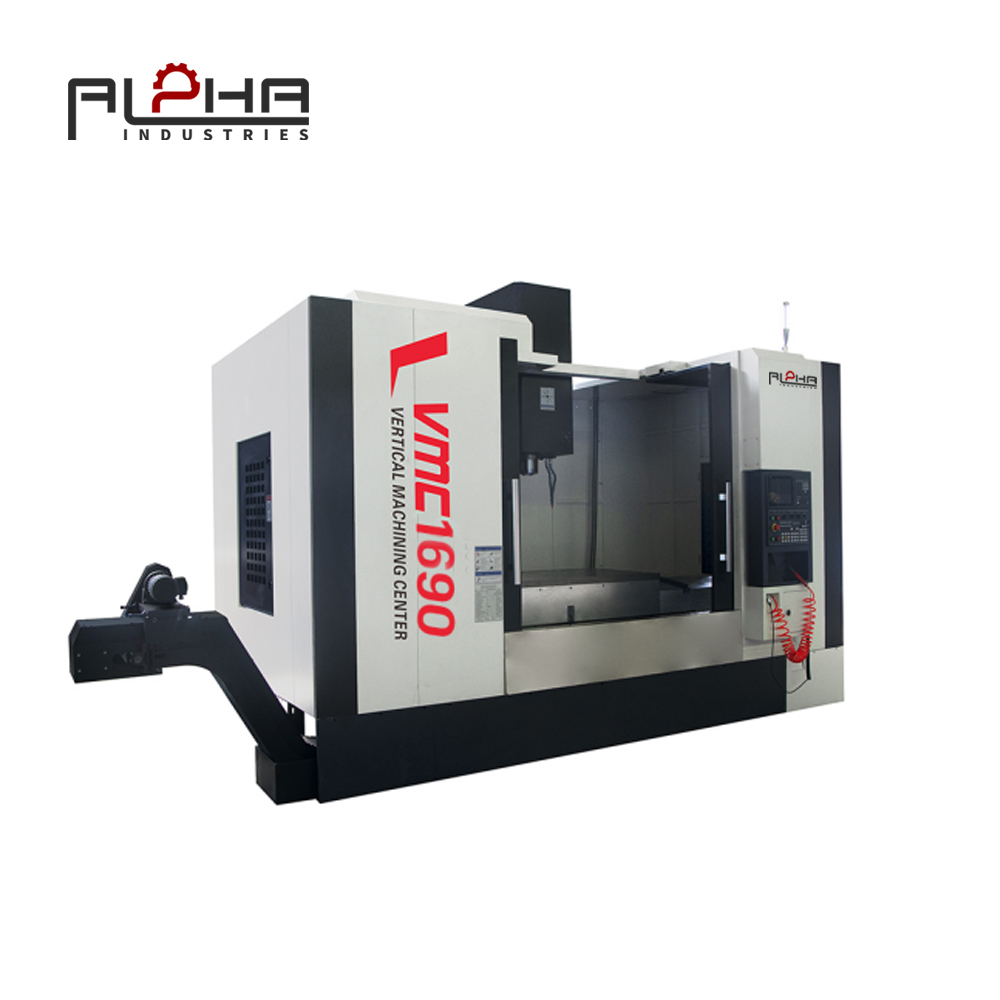

Vertical Machine Center in Medical Implant Production

Medical implants demand exceptional accuracy, flawless surface finish, and strict quality control. A Vertical Machine Center (VMC) is the ideal solution for manufacturing orthopedic implants, dental implants, and prosthetic components. With high-speed spindles, thermal stability, and probing systems, VMCs ensure implants meet international medical standards for safety and functionality.

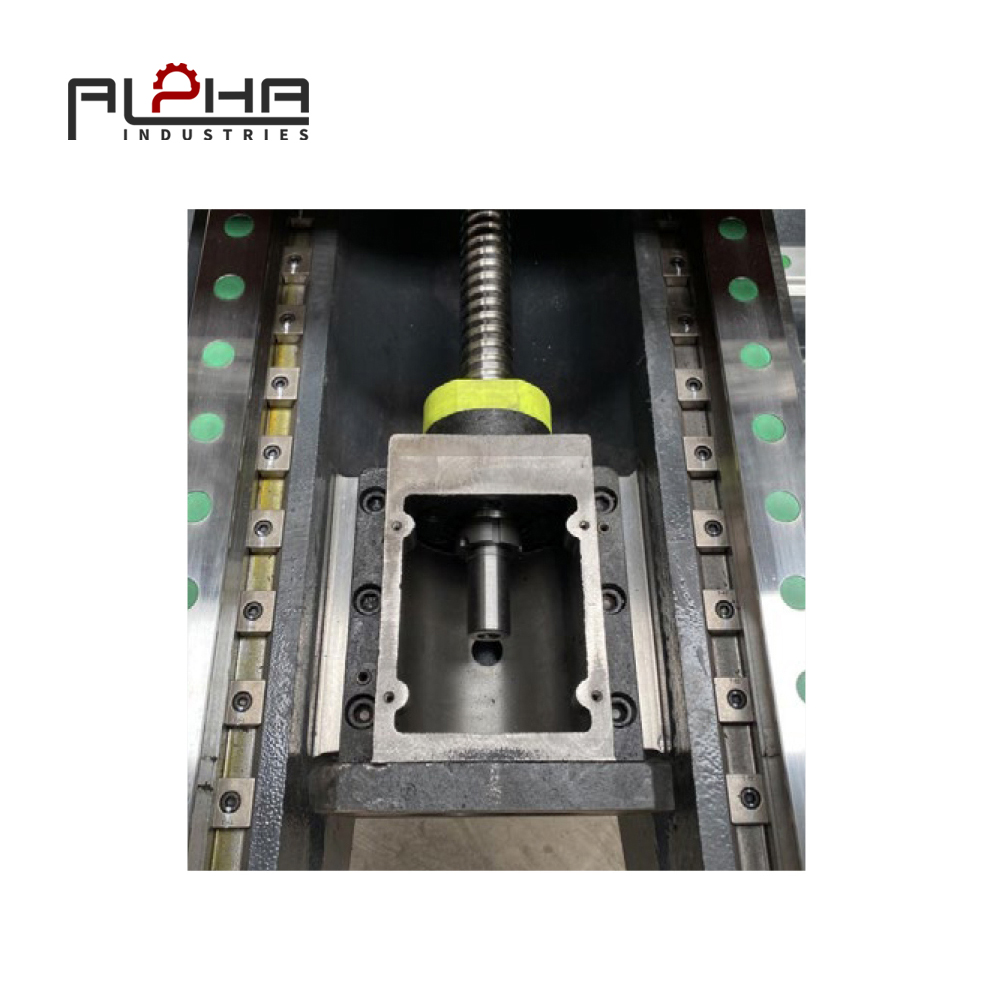

Precision and Accuracy in Implant Machining

Implants such as hip joints, bone plates, and dental screws require tolerances often below ±5 microns. The rigid frame design and backlash-free ball screws in a VMC ensure dimensional stability throughout complex machining cycles. This high level of accuracy guarantees that implants achieve the perfect anatomical fit.

Biocompatible Material Processing with VMC

Most medical implants are made of titanium, cobalt-chrome alloys, and stainless steel, which are difficult to machine due to their hardness and heat resistance. VMCs equipped with high-torque spindles, advanced cooling, and optimized cutting parameters can efficiently machine these materials without compromising their structural integrity or biocompatibility.

Surface Finish and Patient Safety

Implant surfaces must be polished to near-mirror finish to ensure tissue compatibility and prevent bacterial accumulation. A Vertical Machine Center provides high-speed finishing with fine tooling, achieving the surface roughness standards required for implant-grade production. This eliminates additional polishing steps and enhances production efficiency.

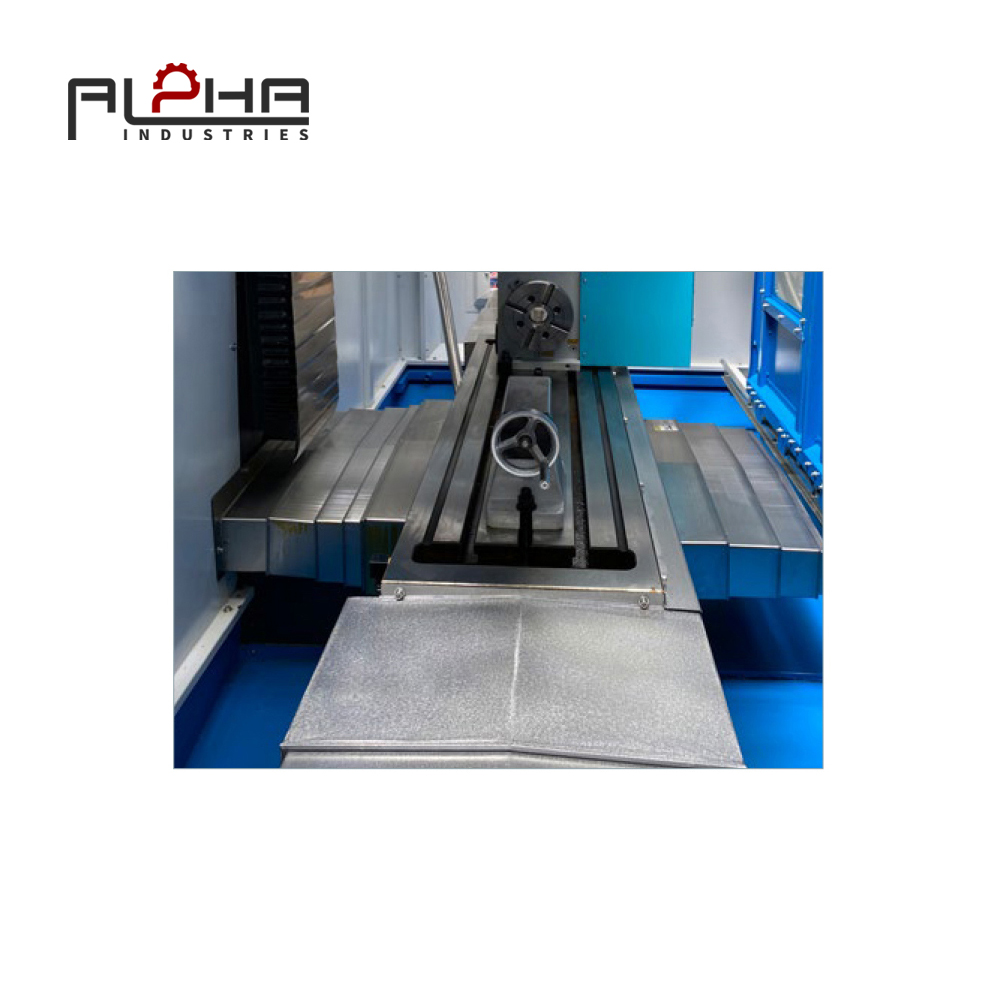

Automation and Consistency in Production

For large-scale medical implant production, consistency is crucial. VMCs integrate Automatic Tool Changers (ATC), probing systems, and process monitoring software to reduce operator dependency. Automated tool life management ensures each implant is machined with the same precision, lowering rejection rates and ensuring compliance with ISO and FDA regulations.

Multi-Axis Capability in Complex Implant Geometry

Implants such as spinal cages and dental abutments involve intricate geometries. VMCs with 4th and 5th-axis machining allow multi-plane cutting, ensuring implants achieve both functional accuracy and aesthetic quality in a single setup. This reduces the risk of dimensional errors and increases throughput.

Quality Control and Regulatory Compliance

Medical implant machining must meet stringent regulatory standards. Advanced VMCs integrate laser measurement, in-process probing, and automated inspection reports. This digital traceability ensures full compliance with ISO 13485 and FDA guidelines, while reducing manual inspection time.

FAQ – People Also Ask

1. Why are Vertical Machine Centers suitable for medical implant production?

VMCs combine precision, rigidity, and automation, making them ideal for machining biocompatible materials to strict medical standards.

2. How do VMCs achieve the required implant surface finish?

By using high-speed finishing tools, adaptive spindle control, and advanced coolant systems, VMCs create smooth, polished surfaces that meet implant requirements.

3. Can a Vertical Machine Center handle titanium used in implants?

Yes, modern VMCs are designed to machine titanium efficiently with high torque spindles, advanced cooling, and optimized cutting parameters.

4. What role does automation play in implant machining?

Automation ensures consistency, reduces defects, and provides traceable quality control, which is vital for medical implant certification.

5. How do Vertical Machine Centers support regulatory compliance?

VMCs with in-process probing and digital inspection generate reliable reports that comply with ISO and FDA standards, reducing audit risks.