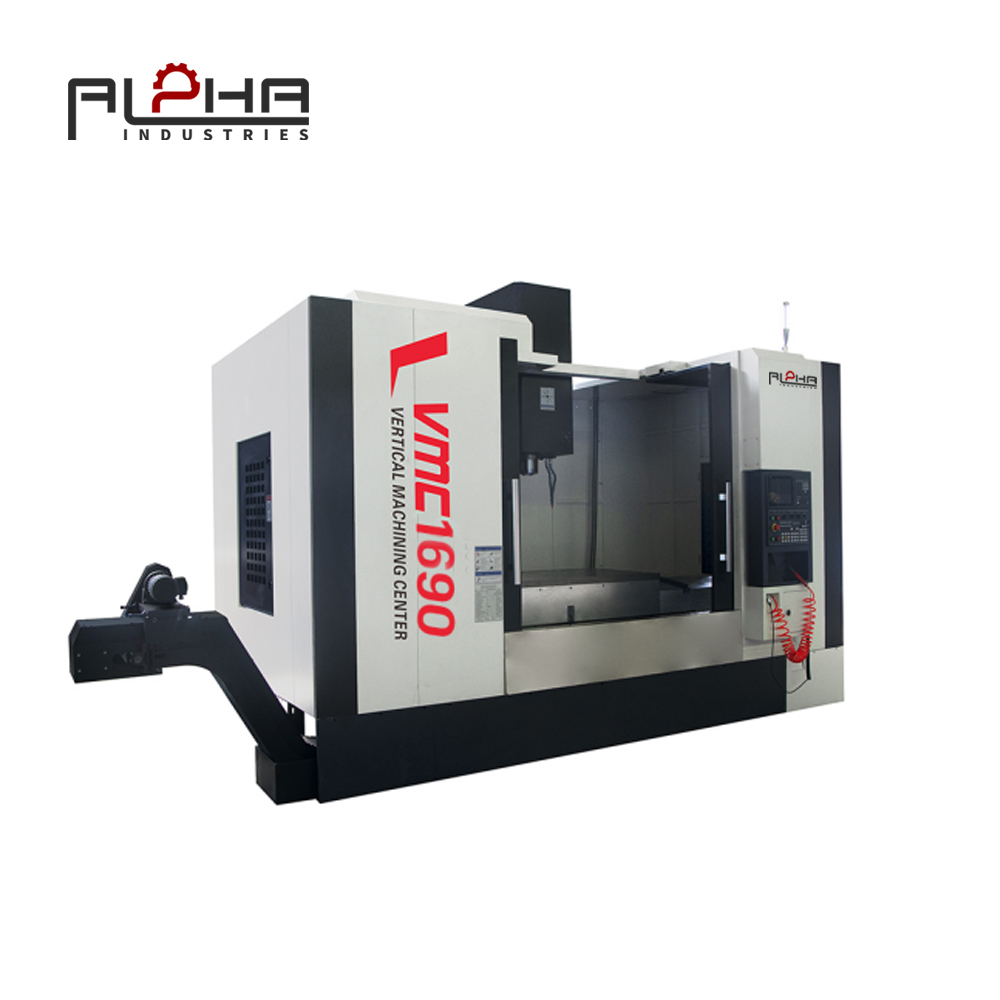

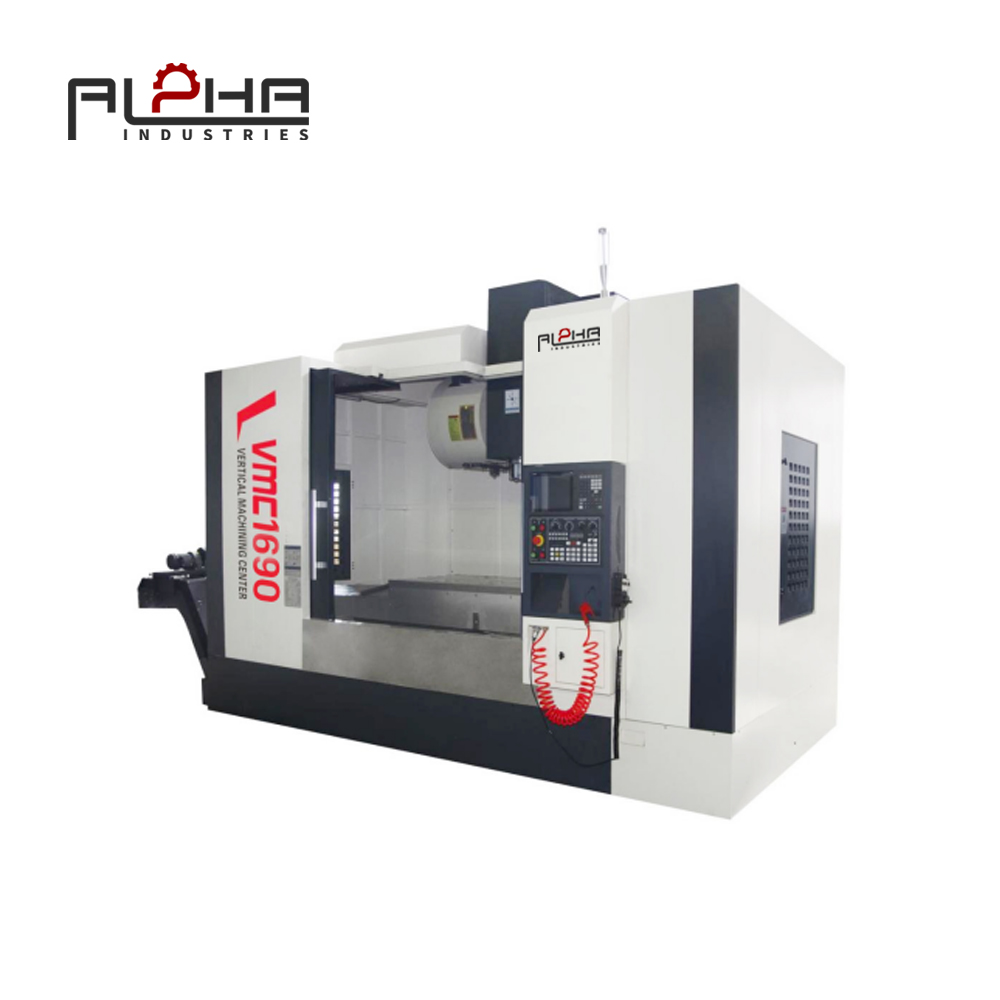

Vertical Machine Center Overview

A Vertical Machine Center (VMC) is a highly versatile milling solution widely used in industries requiring precision machining of metal components. At Alpha, our VMC series is engineered to combine accuracy, rigidity, and efficiency to meet the demands of both high-volume production and intricate part manufacturing.

Equipped with advanced spindle systems, rigid structural design, and user-friendly control interfaces, Alpha’s VMC models deliver exceptional performance for milling, drilling, tapping, and contouring operations.

Key Features of Alpha Vertical Machine Center

-

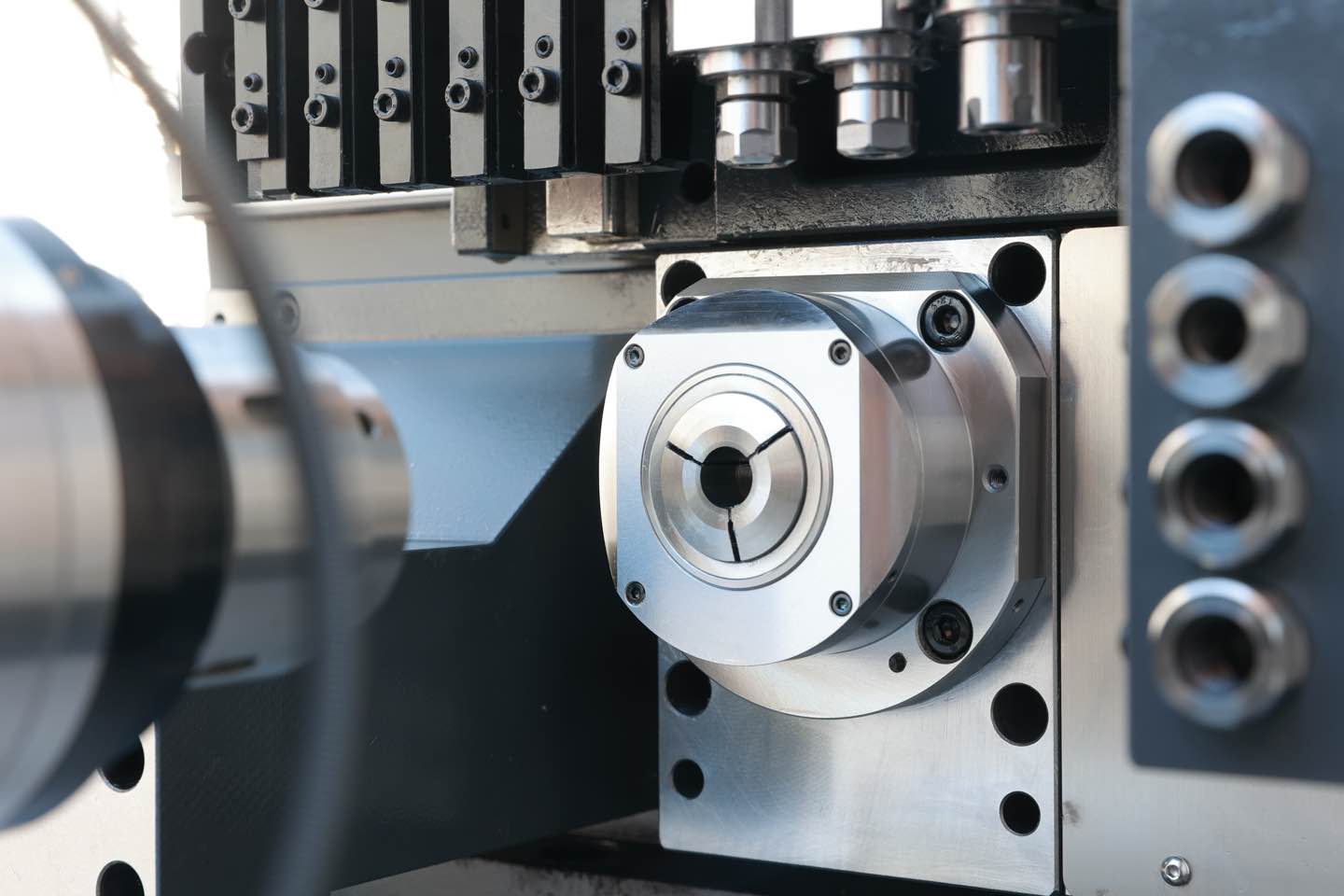

High-Precision Spindle System – Balanced and thermally stable spindle ensures superior surface finish and dimensional accuracy.

-

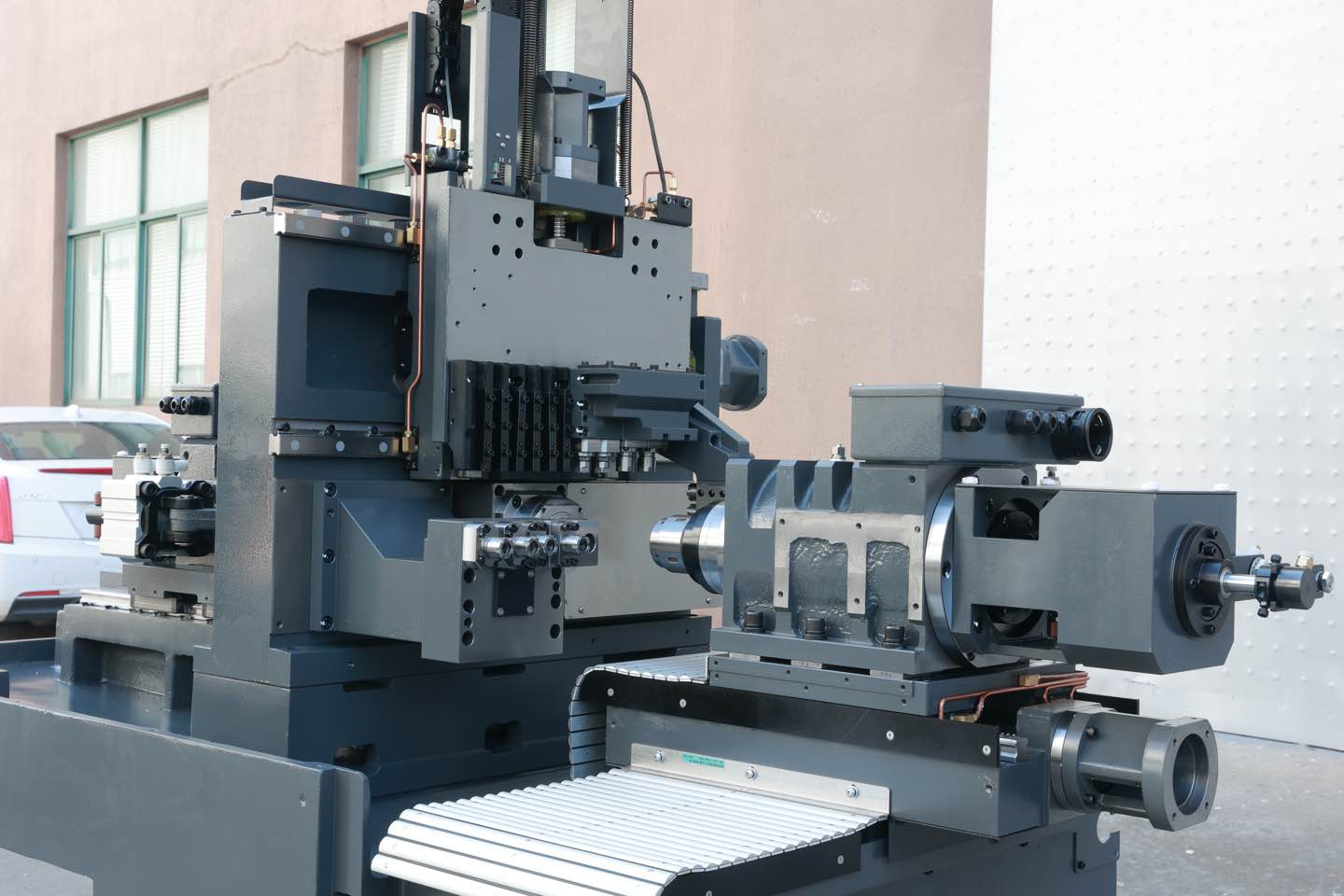

Rigid Machine Structure – Heavy-duty cast iron base and column minimize vibration for stable cutting.

-

Advanced CNC Control – Fast response and user-friendly interface for efficient programming and operation.

-

High-Speed Tool Changer – Reduces cycle time for better productivity.

-

Efficient Chip Removal System – Dual-screw conveyors and coolant system for continuous operation.

Applications of Vertical Machine Center

Alpha’s VMC machines are ideal for producing precision components in industries such as:

-

Aerospace – Complex aluminum and titanium components.

-

Automotive – Engine parts, gear housings, and molds.

-

Electronics – High-precision enclosures and heat sinks.

-

Mold & Die Making – Injection mold cavities and die plates.

-

General Manufacturing – Custom parts and prototyping.

Technical Advantages of Alpha VMC

-

Precision Tolerances: Achievable accuracy within ±0.005 mm.

-

Fast Feed Rates: Up to 36 m/min rapid traverse.

-

Versatile Machining: Supports 3-axis and optional 4/5-axis configurations.

-

Energy Efficiency: Optimized power consumption for sustainable production.

-

Long Service Life: Wear-resistant guideways and spindle bearings.

Why Choose Alpha for Your Vertical Machine Center

-

Proven Manufacturing Expertise – Over a decade of designing and building high-performance machine tools.

-

Customizable Solutions – Configurations tailored to your production needs.

-

Global Support Network – Fast delivery and after-sales service in over 35 countries.

-

Competitive Pricing – Quality machines at cost-effective rates.

Frequently Asked Questions about Vertical Machine Center

1. What is a Vertical Machine Center used for?

A VMC is used for precision milling, drilling, tapping, and contouring of metal and non-metal workpieces.

2. How does a VMC improve machining accuracy?

Its rigid structure, precision spindle, and advanced CNC controls ensure minimal vibration and consistent dimensions.

3. Can a VMC handle large workpieces?

Yes, depending on the table size and travel capacity, Alpha VMC models can machine both small and large parts.

4. What is the difference between a VMC and a horizontal machining center?

A VMC has a vertically oriented spindle, ideal for flat workpieces, while a horizontal machining center offers better chip evacuation for deep cavities.

5. Does Alpha provide customized VMC configurations?

Yes, Alpha offers tailored spindle speeds, tool capacity, and axis configurations to match your production requirements.

Call to Action:

Get Your Precision Vertical Machine Center Today – Contact Alpha for a Customized Quote