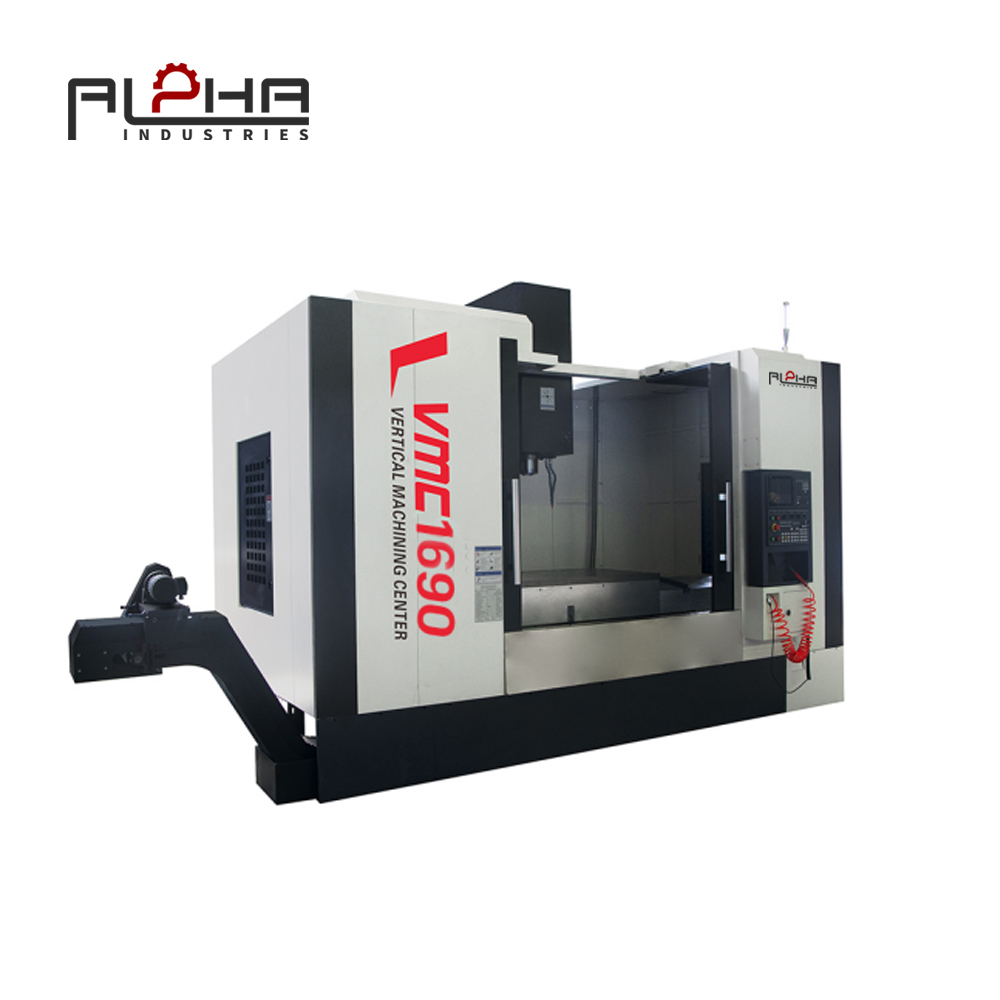

Vertical Machine Center – Advanced CNC Machining by Alpha

A Vertical Machine Center (VMC) is a highly versatile CNC milling machine designed for vertical spindle orientation, enabling efficient and precise cutting, drilling, and milling operations. At Alpha, we specialize in manufacturing high-performance VMCs engineered for superior accuracy, speed, and durability to meet the demands of modern manufacturing.

1. What is a Vertical Machine Center?

A VMC machine is a type of CNC machining center with a vertically oriented spindle, ideal for machining flat surfaces, complex contours, and precision components. The design allows easy workpiece clamping and enhanced chip removal efficiency.

2. Key Features of Alpha’s VMC Machines

-

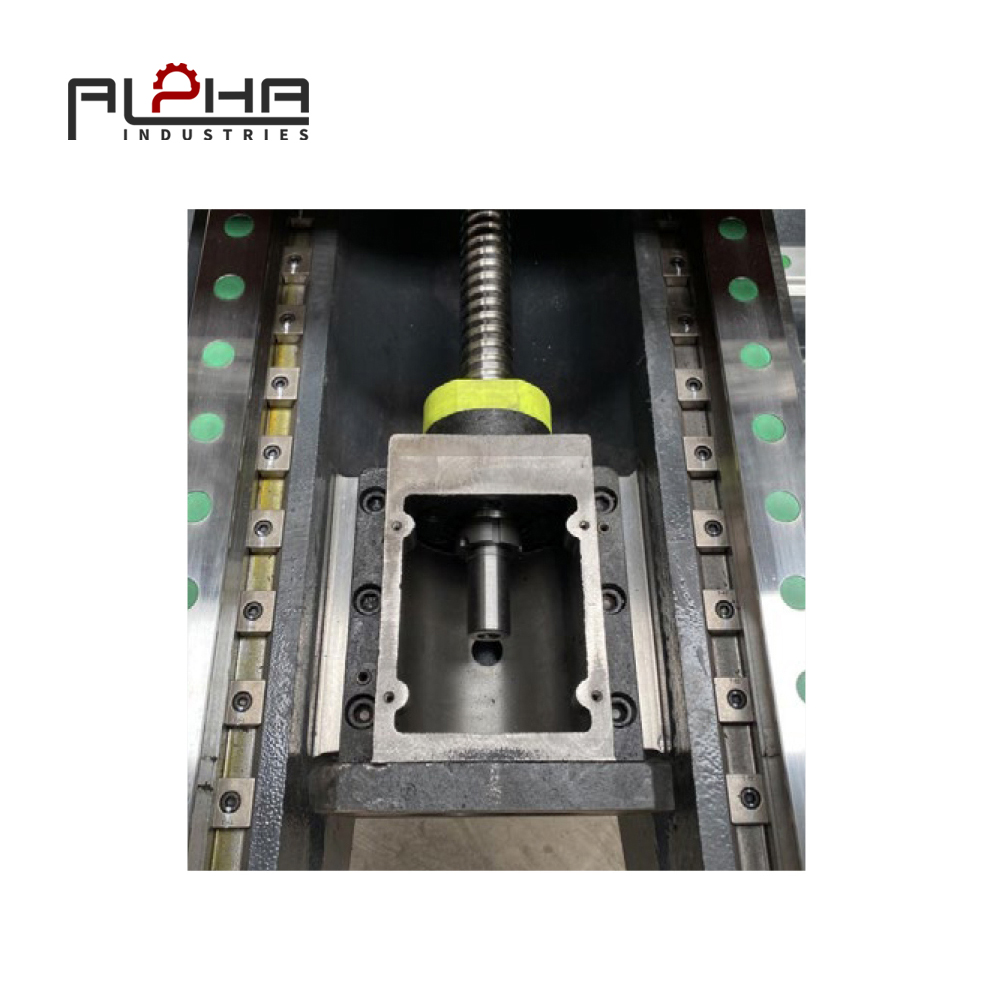

High Precision Spindle – Ensures stable performance with minimal runout, ideal for high-tolerance parts.

-

Rigid Machine Structure – Heavy-duty cast iron frame for reduced vibration and improved machining accuracy.

-

Advanced CNC Control – Supports complex multi-axis machining with user-friendly programming.

-

Efficient Chip Removal – Optimized coolant and chip conveyor systems for continuous production.

-

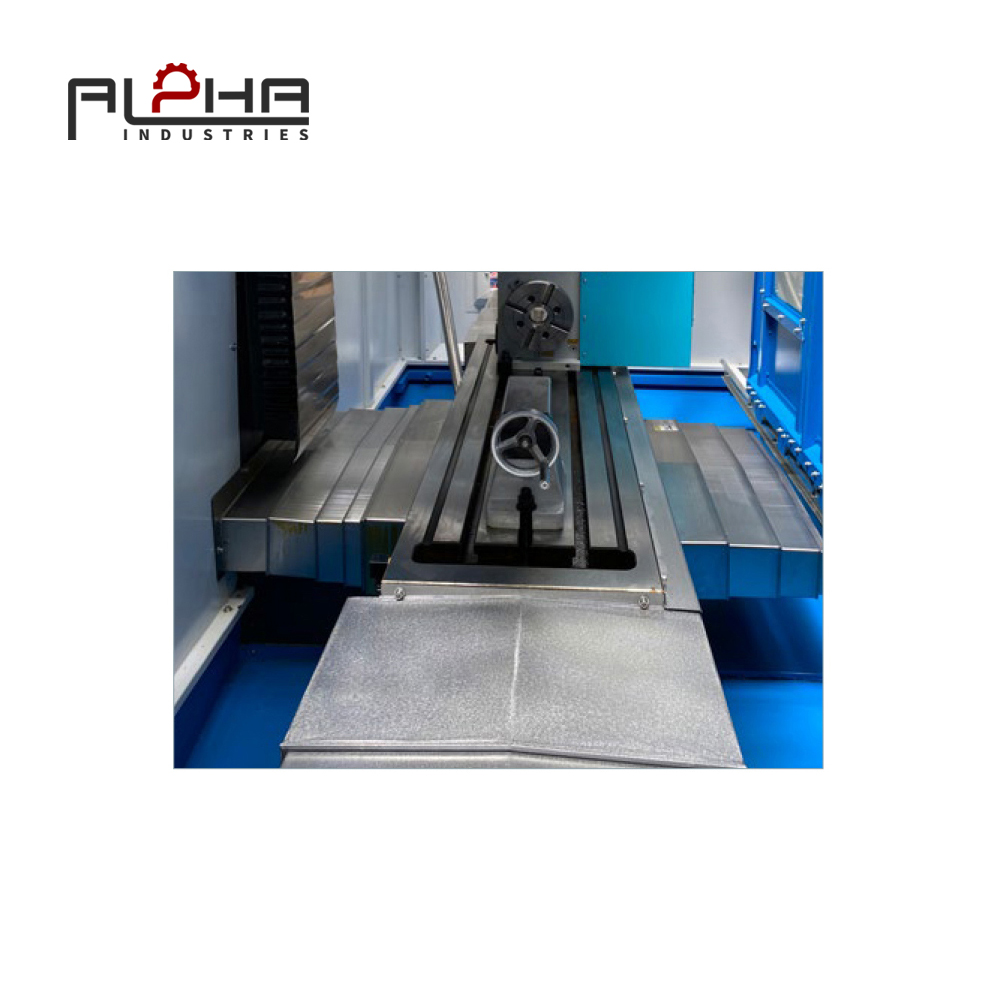

Wide Worktable Capacity – Suitable for small to large workpieces in different industries.

3. Advantages of Choosing a VMC

-

Superior Accuracy – Vertical design offers exceptional positional precision.

-

Space Efficiency – Compact footprint suitable for workshops and production lines.

-

Flexibility – Handles diverse operations like drilling, boring, tapping, and milling.

-

Cost-Effective Production – Reduces setup time and improves throughput.

4. Applications Across Industries

Alpha’s Vertical Machine Centers are widely used in:

-

Automotive – Engine parts, gear housings, transmission components.

-

Aerospace – Structural parts, turbine components, precision brackets.

-

Mold Making – Injection molds, die casting molds, prototype tooling.

-

Metalworking – Custom components, sheet metal parts, industrial fittings.

5. Why Choose Alpha’s VMC Solutions

At Alpha, we combine cutting-edge technology, robust engineering, and strict quality control to deliver reliable VMC machines. Our models are designed to reduce downtime, improve machining accuracy, and meet global manufacturing standards.

FAQ – Vertical Machine Center

Q1: What is the difference between a Vertical Machine Center and a Horizontal Machine Center?

A VMC has a vertical spindle orientation, ideal for flat surface machining, while an HMC has a horizontal spindle for better chip evacuation in heavy-duty cutting.

Q2: Can Alpha’s VMC handle large workpieces?

Yes, our large-format VMCs feature extended worktables and increased spindle travel for oversized components.

Q3: How do I maintain a VMC machine?

Regular lubrication, coolant monitoring, alignment checks, and timely part replacement ensure optimal performance.

Q4: Does Alpha offer custom VMC solutions?

Yes, we can customize spindle speed, table size, and CNC control systems according to your production needs.

Call to Action:

Upgrade your production with Alpha’s Vertical Machine Centers – precision, performance, and reliability in one machine. Contact us today for a tailored solution.