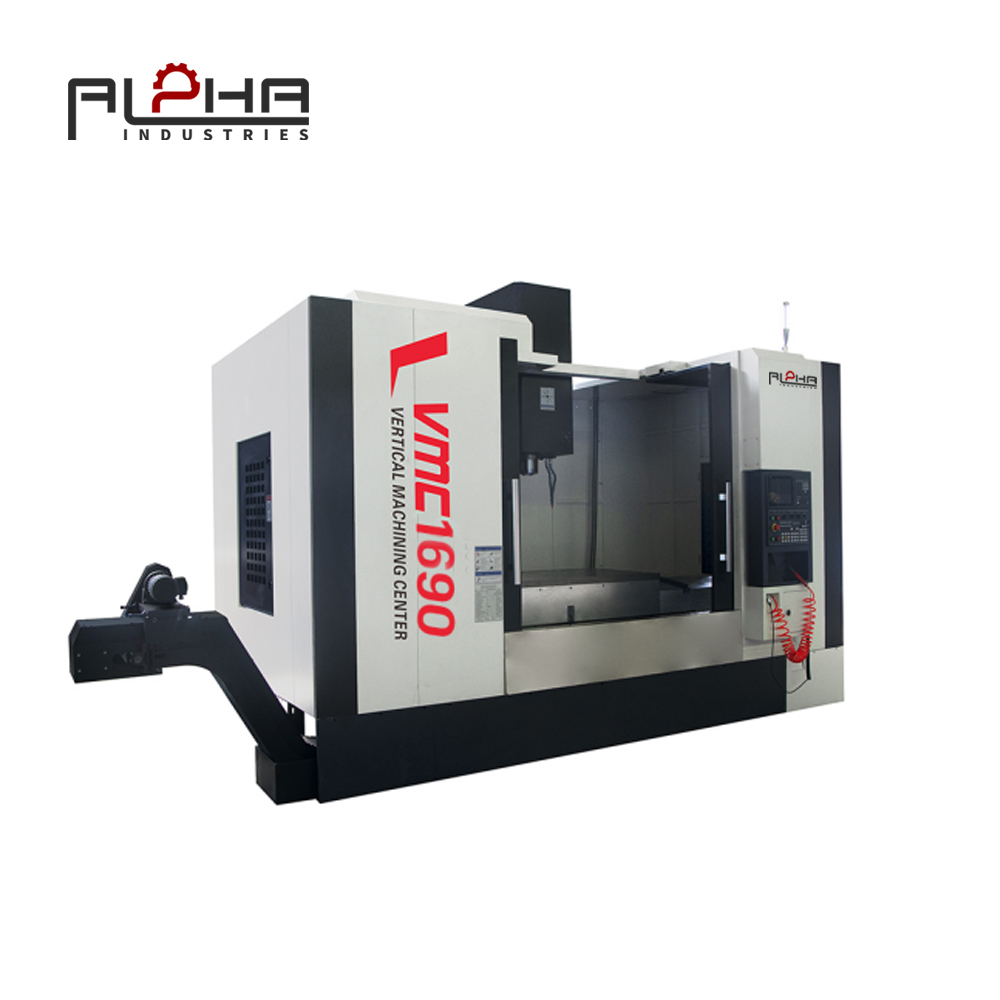

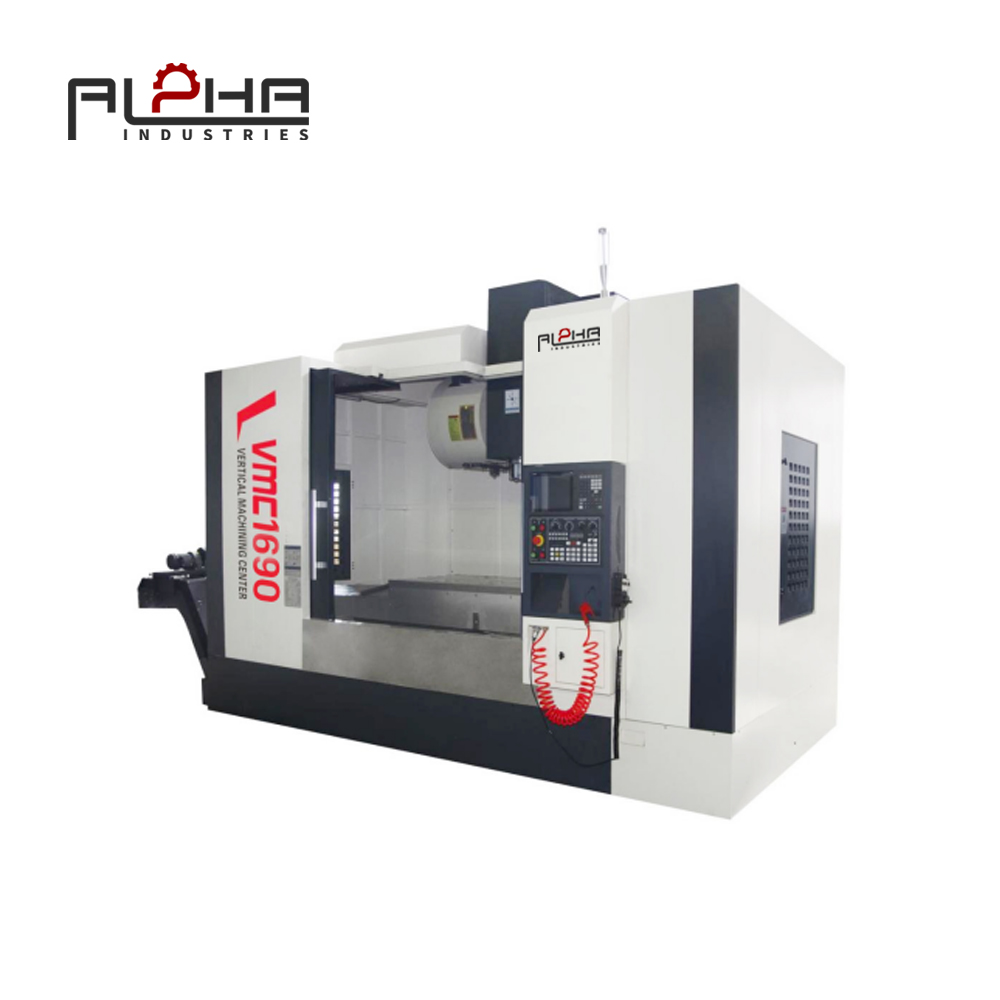

Introduction to Vertical Machine Center (VMC)

A Vertical Machine Center (VMC) is a highly versatile machining solution designed for precision milling, drilling, tapping, and boring. With the spindle positioned vertically, the VMC offers exceptional accuracy, stability, and efficiency in various manufacturing applications. At Alpha, our VMC series combines high-speed performance, superior rigidity, and intelligent control systems to meet the demands of modern industries.

Key Features of Alpha Vertical Machine Center

-

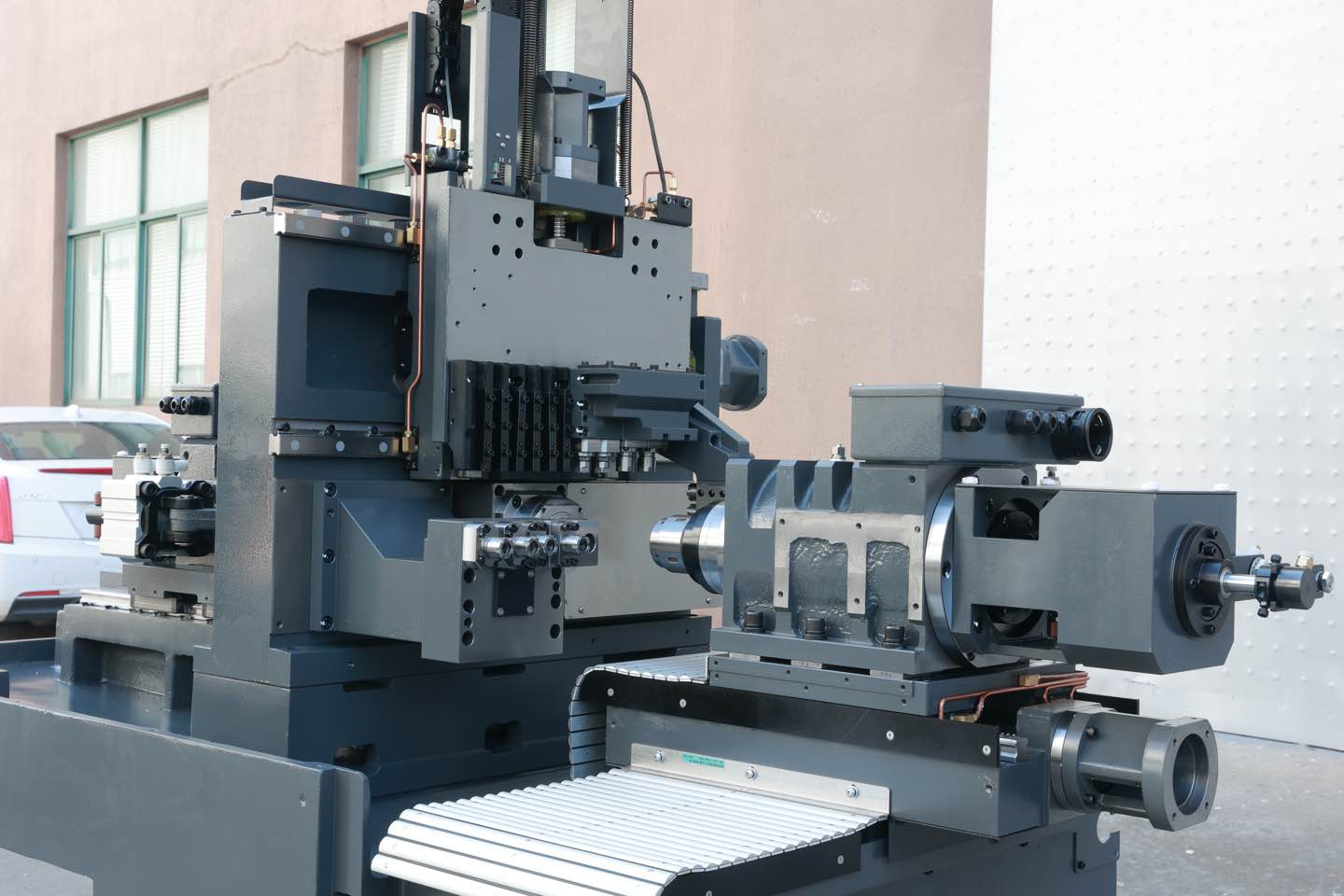

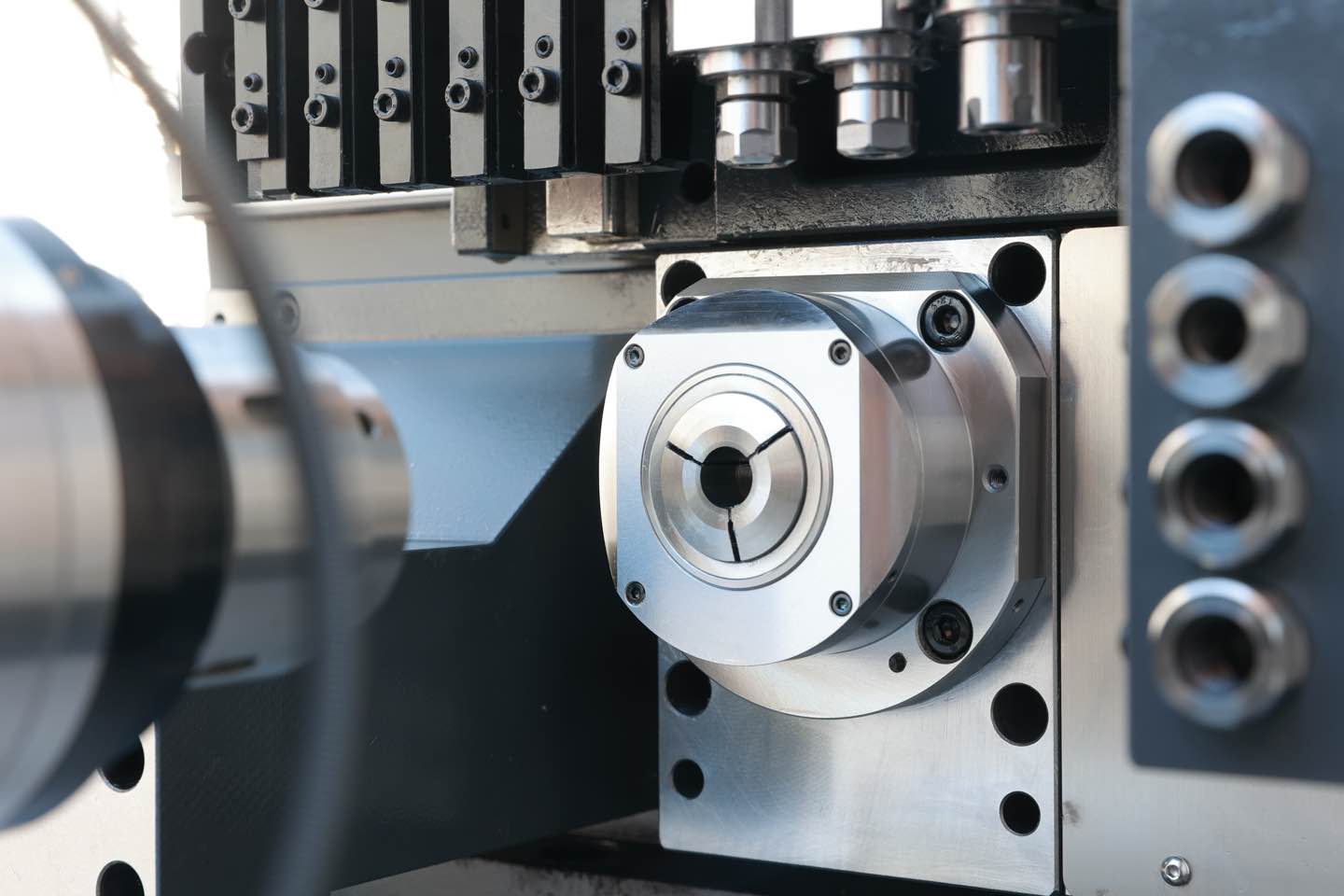

High Precision Spindle System – Advanced spindle bearings and temperature control ensure consistent accuracy during prolonged operations.

-

Rigid Machine Structure – Heavy-duty cast iron frames reduce vibration and enhance cutting stability.

-

High-Speed Tool Change – Automatic tool changers (ATC) with rapid swap capability improve productivity.

-

Advanced CNC Control – User-friendly interfaces with customizable machining cycles.

-

Enhanced Cooling & Chip Removal – Efficient coolant systems maintain tool life and surface quality.

Applications of Alpha VMC

Our Vertical Machine Centers are widely used in:

-

Automotive Components Manufacturing

-

Aerospace Parts Production

-

Precision Mold and Die Making

-

Medical Device Machining

-

General Industrial Components

Advantages of Choosing Alpha VMC

-

Superior Surface Finish – Achieve mirror-like finishes with precision cutting.

-

High Productivity – Reduced cycle times through optimized programming.

-

Versatility – Suitable for complex 3-axis and multi-operation machining.

-

Reliability – Built for continuous, long-term industrial use.

FAQs:

1. What is the main advantage of a Vertical Machine Center?

A VMC provides exceptional accuracy and ease of operation, making it ideal for high-precision machining tasks with faster setup times.

2. How does Alpha ensure the accuracy of its VMC?

We use rigid casting designs, precision spindle bearings, and advanced CNC controls to maintain high positioning accuracy.

3. Can Alpha VMC handle heavy-duty machining?

Yes. With robust construction and high-torque spindles, Alpha VMC machines can process both light and heavy materials.

4. What industries benefit most from Alpha VMC?

Industries such as aerospace, automotive, medical, and mold manufacturing greatly benefit from VMC technology.

5. Does Alpha offer customization for VMC machines?

Yes. Alpha provides tailored solutions including spindle speed options, table sizes, and automation upgrades.

Call to Action

Upgrade your manufacturing capability with Alpha Vertical Machine Center – delivering precision, efficiency, and innovation for your business.