Engineered Stability with Flat Bed CNC Lathe

Flat bed CNC lathes are well-known for their structural simplicity, long-axis support, and excellent load-bearing performance. ALPHA’s CNC Lathe Flat Bed is built to serve applications requiring consistent axial accuracy across extended lengths—ideal for shaft work, long cylindrical parts, and large-diameter components.

Key Features of the Flat Bed Structure

This machine features a horizontal flat bed design with a wide guideway base, allowing superior longitudinal stability. The bed is a single-piece, high-rigidity casting structure with fine-machined and hardened surfaces to ensure low wear and long operational lifespan.

Flat bed design supports robust tailstock and steady rest positioning, ensuring minimal deflection during extended part machining.

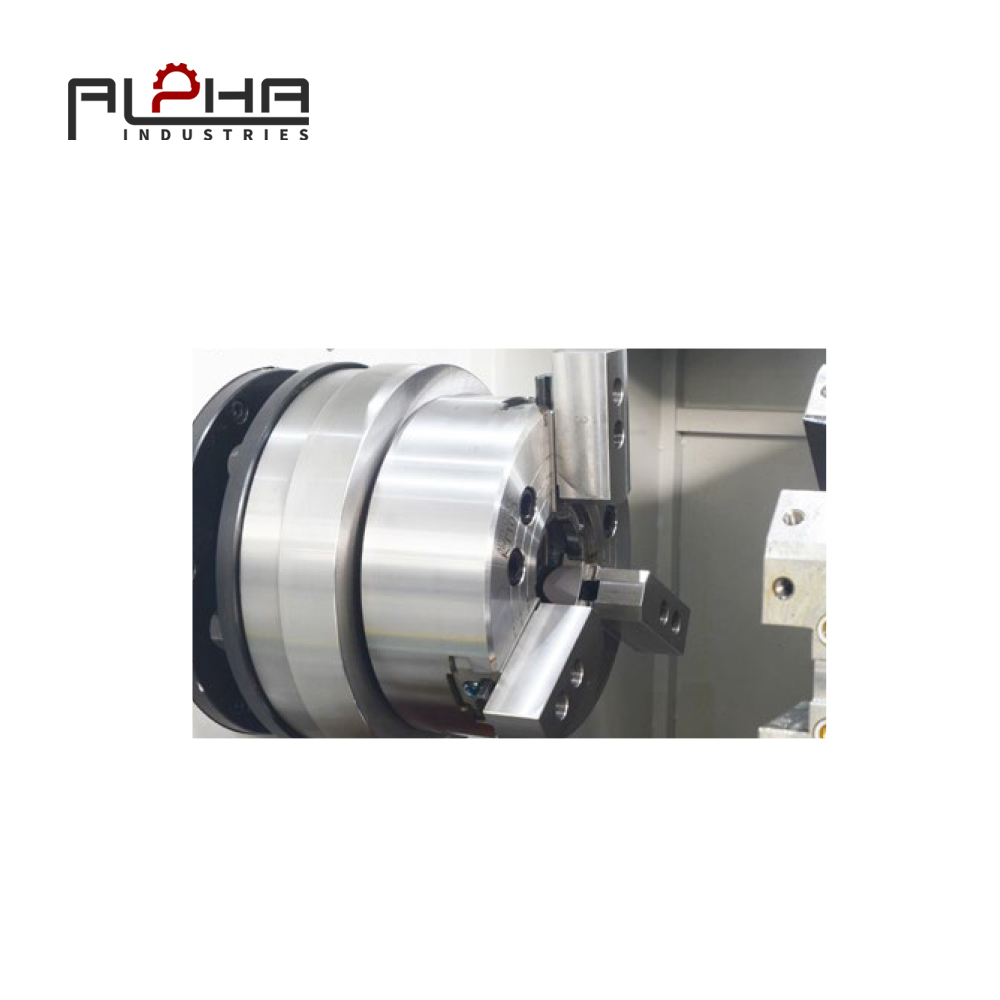

Spindle and Chucking Versatility

The spindle system supports a wide range of chuck diameters and is available in both belt-driven and direct-drive types based on torque and speed requirements. Heavy-duty bearings provide radial rigidity, allowing the spindle to handle large parts or off-center loads with consistent concentricity.

A hydraulic or pneumatic chuck can be installed for high-speed production setups, and the spindle bore allows through-bar feeding for long stock machining.

Broad Compatibility with Tool Holders and Automation

ALPHA’s CNC Lathe Flat Bed supports both manual and automatic tool turrets with multi-position configurations. Tools are rigidly clamped for heavy-duty and rough machining tasks. The machine is also compatible with programmable tailstocks, bar feeders, and auto parts catchers to facilitate both batch and small-lot production.

Use Cases in Medium to Large Component Production

The machine is commonly used in:

-

Hydraulic cylinder turning

-

Printing roll and shaft machining

-

Pipe threading and boring

-

Construction equipment part manufacturing

Its long-bed design is ideal for industries where part stability and tool access over distance are critical.

Advantages Over Inclined Bed Configurations

While slant beds offer better chip evacuation, the flat bed excels in supporting heavier and longer parts, making it the preferred structure for shaft-type or large-diameter components. Flat beds also allow easier manual intervention, setup, and adjustment.

FAQs:

What is the benefit of using a flat bed CNC lathe?

It provides better support for long or heavy parts, with wider guideways and improved axial load handling.

Is a flat bed lathe good for pipe threading operations?

Yes. With stable tailstock support and through-hole spindles, it is suitable for threading long pipes or hollow shafts.

Can flat bed CNC lathes be customized for extra length?

Absolutely. ALPHA offers extended bed lengths and travel distances for specific industrial applications.

What types of chucks can be used with a flat bed lathe?

Manual, hydraulic, and pneumatic chucks of different sizes can be mounted depending on workholding needs.

Does ALPHA support automation options for flat bed lathes?

Yes. Automation like bar feeders, robotic arms, and conveyors can be integrated for enhanced productivity.