CNC Lathe Flat Bed for Stable Heavy-Duty Turning by ALPHA

In industrial sectors where accuracy and mass production coexist, the CNC Lathe Flat Bed offers unmatched performance in machining large and heavy components. ALPHA designs its flat bed CNC lathes with a strong focus on structural rigidity, dimensional accuracy, and cost-effective productivity, ensuring long-term operation under high-load conditions.

Structural Integrity and Design of the CNC Lathe Flat Bed

One of the most distinguishing features of the flat bed CNC lathe is its low center of gravity and robust base casting, typically manufactured from HT300 grade cast iron. This ensures superior vibration damping, making it ideal for large-diameter shaft turning or faceplate operations where stability directly influences surface finish quality.

The flat bed layout accommodates tailstock support for longer workpieces, essential for oil field equipment, power transmission shafts, and heavy flanges.

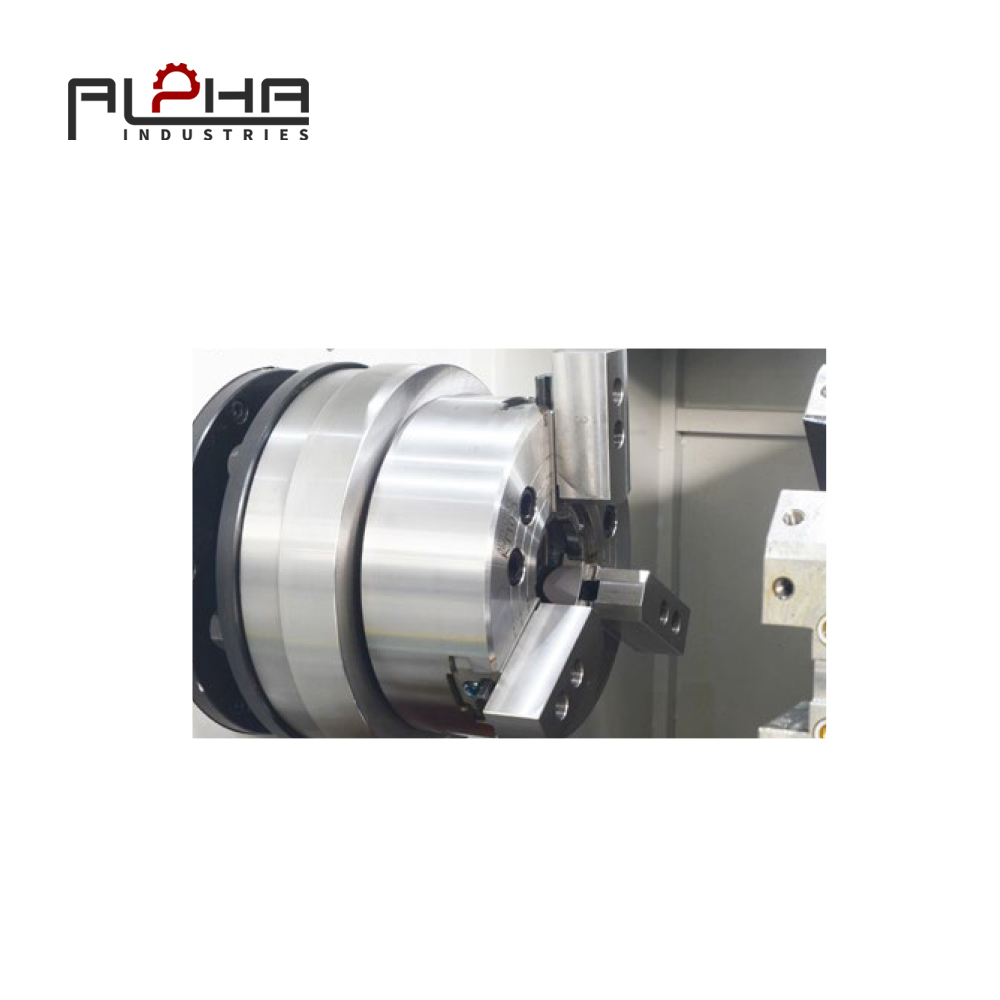

Precision Spindle Assembly for High Axial Load Machining

ALPHA’s CNC flat bed lathe integrates a high-precision spindle unit, often supported by taper roller bearings or angular contact ball bearings, offering excellent axial and radial load-bearing capacity. The spindle bore can be customized (e.g., Ø105 mm or larger), allowing for the feeding of longer bars or hollow tubes directly into the chuck area.

The main spindle is powered by a servo motor with constant torque output, ensuring optimal cutting speed during both rough and fine passes.

Box Way or Hardened Guideways for Rigidity and Longevity

Compared to linear rails, the box way guide system on ALPHA’s flat bed CNC lathe significantly improves the resistance against cutting force deflection. These induction-hardened and Turcite-coated sliding surfaces provide long-term durability with low friction, suitable for interrupted cuts and deep turning operations in hard materials.

This makes it the preferred configuration in mold base turning, mining component machining, and energy sector applications.

Advanced Control System with Customizable Programming

ALPHA CNC flat bed lathes are equipped with open-architecture control platforms compatible with standard G-code and support various optional automation interfaces, including automatic tool changers (ATC) and hydraulic chucking systems.

The system ensures:

-

Real-time feedback control

-

Tool wear offset correction

-

Multi-pass threading cycles

-

Large memory capacity for complex contour programming

Applications of CNC Lathe Flat Bed in Heavy Industry

This machine is widely adopted in sectors where turning performance must not be compromised by load:

-

Steel mill roller refurbishment

-

Wind turbine shaft machining

-

Heavy vehicle axle production

-

Pipeline connector threading

-

Hydraulic cylinder tube turning

With tailored workholding and robust structural design, it handles complex geometries and extended lengths with ease.

Material Handling and Safety Features

ALPHA incorporates:

-

Hydraulic tailstock quill

-

Chip conveyor integration

-

Full enclosure for coolant containment

-

Automatic lubrication systems

These features optimize uptime and reduce manual intervention, improving workshop safety and cleanliness.

Frequently Asked Questions (People Also Ask)

What makes a flat bed CNC lathe better for large workpieces?

The flat bed structure provides extended support and rigidity, especially for components over 1000 mm in length. This minimizes deflection and ensures better turning accuracy.

Can a CNC lathe flat bed handle interrupted cutting?

Yes, the box-way design and rigid tool post of ALPHA’s CNC flat bed lathe allow it to withstand high-impact interrupted cuts, such as roughing forged parts or castings.

What industries benefit most from CNC lathe flat bed machines?

Industries such as energy, transportation, metallurgy, and infrastructure development often use flat bed CNC lathes for their ability to machine large-diameter, long, and heavy-duty parts.

Does ALPHA provide customized solutions for flat bed CNC lathes?

Absolutely. ALPHA offers customization of spindle bore, bed length, tool turret type, and automation interfaces to match specific machining needs.

Is a flat bed CNC lathe suitable for high-volume production?

Yes. While it’s built for heavy-duty machining, the integration of automated tool changers and programmable cycles makes it efficient for batch production as well.

Explore Precision. Experience ALPHA.

ALPHA’s CNC Lathe Flat Bed series delivers uncompromising precision and power for demanding industrial environments.