In modern power transmission systems, gear accuracy defines the performance, noise level, and efficiency of machinery. From automotive gearboxes to heavy-duty industrial reducers, gear tooth geometry directly influences torque transfer and operational smoothness.

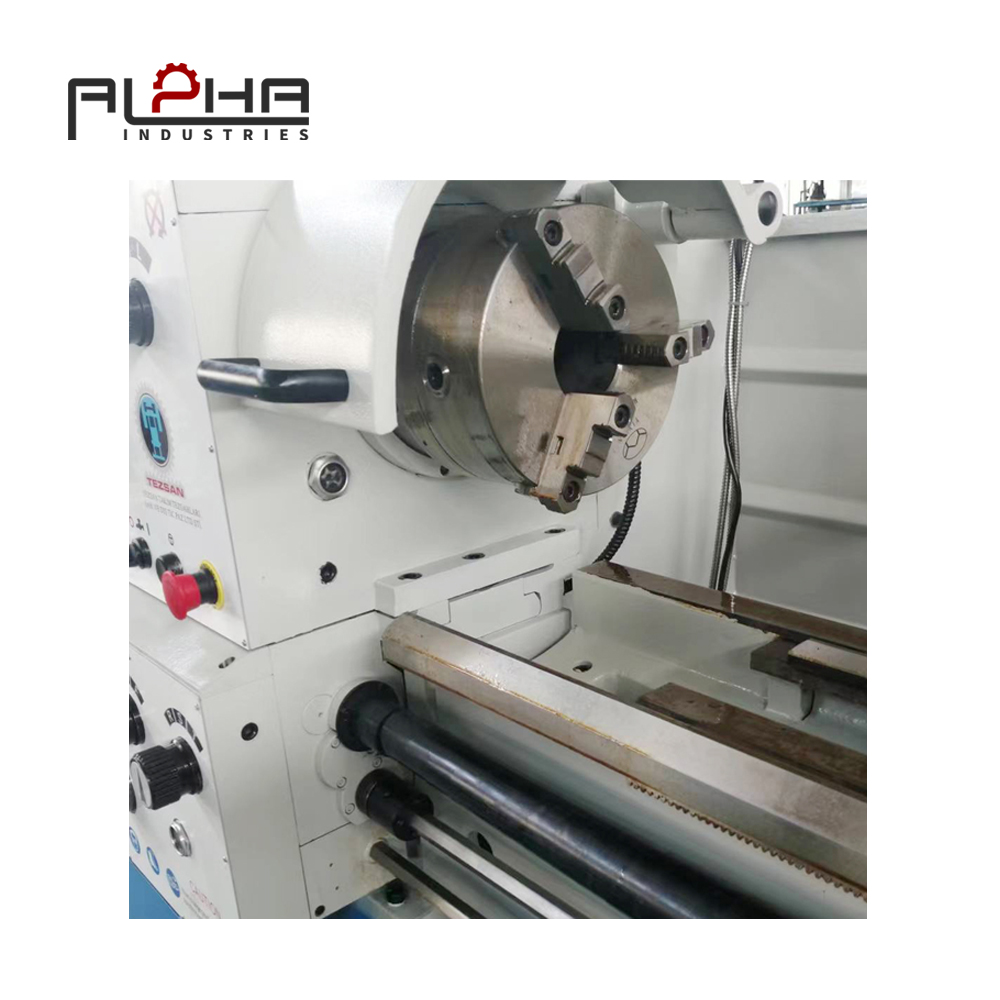

At the heart of this process lies the Gear Hobbing Machine—a specialized tool engineered to cut precise gear teeth using a rotating hob cutter.

Alpha’s Gear Hobbing Machines deliver unmatched precision, repeatability, and rigidity, enabling manufacturers to produce spur, helical, worm, and spline gears with exceptional accuracy.

Focus Point: High-Precision Gear Tooth Forming

1. The Principle of Gear Hobbing

Gear hobbing is a continuous generating process where the hob (a cutting tool resembling a worm) rotates in synchronization with the workpiece.

Each revolution of the hob gradually removes material, forming the gear’s teeth through indexing and feed motion.

The result is a perfectly conjugate tooth profile—a key factor for smooth meshing and long gear life.

2. Gear Tooth Accuracy: Defining Performance

The precision of gear teeth affects several critical parameters:

-

Transmission Accuracy (Grade 5–6): Ensures minimal angular error between driver and driven gears.

-

Surface Finish (Ra ≤ 0.8 µm): Guarantees quieter operation and reduced wear.

-

Tooth Profile Deviation (≤ 0.003 mm): Essential for uniform load distribution across gear teeth.

Alpha’s hobbing machines are designed to maintain these tolerances even during long production cycles and high-speed cutting operations.

Advanced Design for Precision and Stability

Rigid Structural Design

The one-piece cast iron base provides maximum vibration damping and thermal stability, reducing deformation and ensuring consistent cutting accuracy.

High-Precision Spindle System

Equipped with preloaded angular contact bearings and a servo-driven rotary table, Alpha’s spindle assembly ensures zero backlash during synchronization, crucial for helical and double-helical gears.

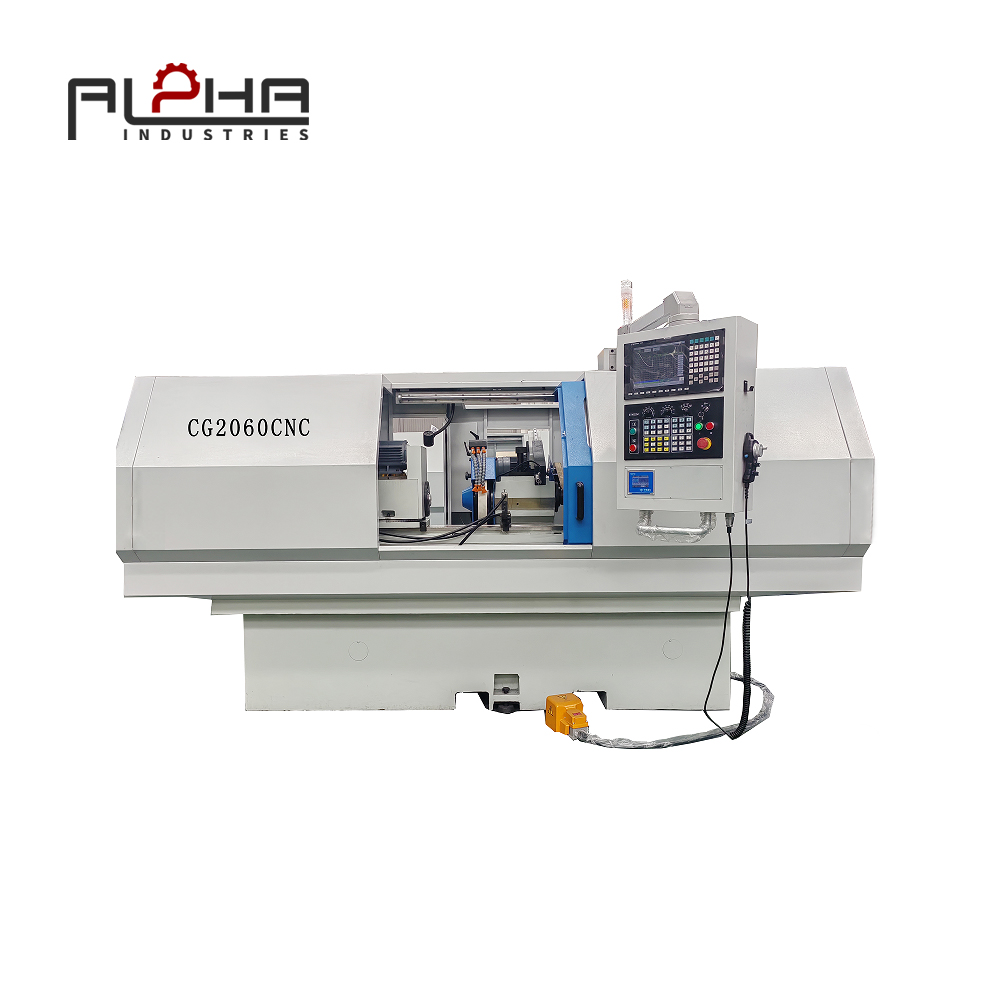

Digital Synchronization Control

Alpha integrates a high-resolution electronic gearbox (EGB) system that digitally synchronizes hob and workpiece rotation.

This innovation eliminates mechanical transmission errors, achieving real-time pitch correction and superior surface consistency.

Automatic Hob Compensation

The system automatically adjusts for tool wear compensation in micron increments, maintaining perfect tooth geometry even in extended production runs.

Superior Surface Quality and Tooth Consistency

Through optimized cutting parameters—such as hob speed, feed rate, and cutting depth—Alpha’s Gear Hobbing Machines produce gears with mirror-like surfaces and uniform tooth flank hardness.

This consistency is vital for precision reducers, robotics, and automotive transmission gears, where even minor deviations can impact operational smoothness and lifespan.

Process Optimization: From Roughing to Finishing

Alpha offers multi-stage hobbing cycles:

-

Rough Hobbing: High material removal rate for pre-machining.

-

Semi-Finish Hobbing: Refines tooth profile and removes roughing marks.

-

Finish Hobbing: Achieves final accuracy and fine surface roughness.

Combined with in-process measurement and CNC feedback control, these stages ensure stable gear quality without the need for regrinding.

Applications Across Industries

| Industry | Application Example |

|---|---|

| Automotive | Transmission gears, differential gears, synchronizer hubs |

| Aerospace | Actuator gears, landing gear drive systems |

| Heavy Machinery | Gearboxes for construction and mining |

| Robotics | High-precision motion gears |

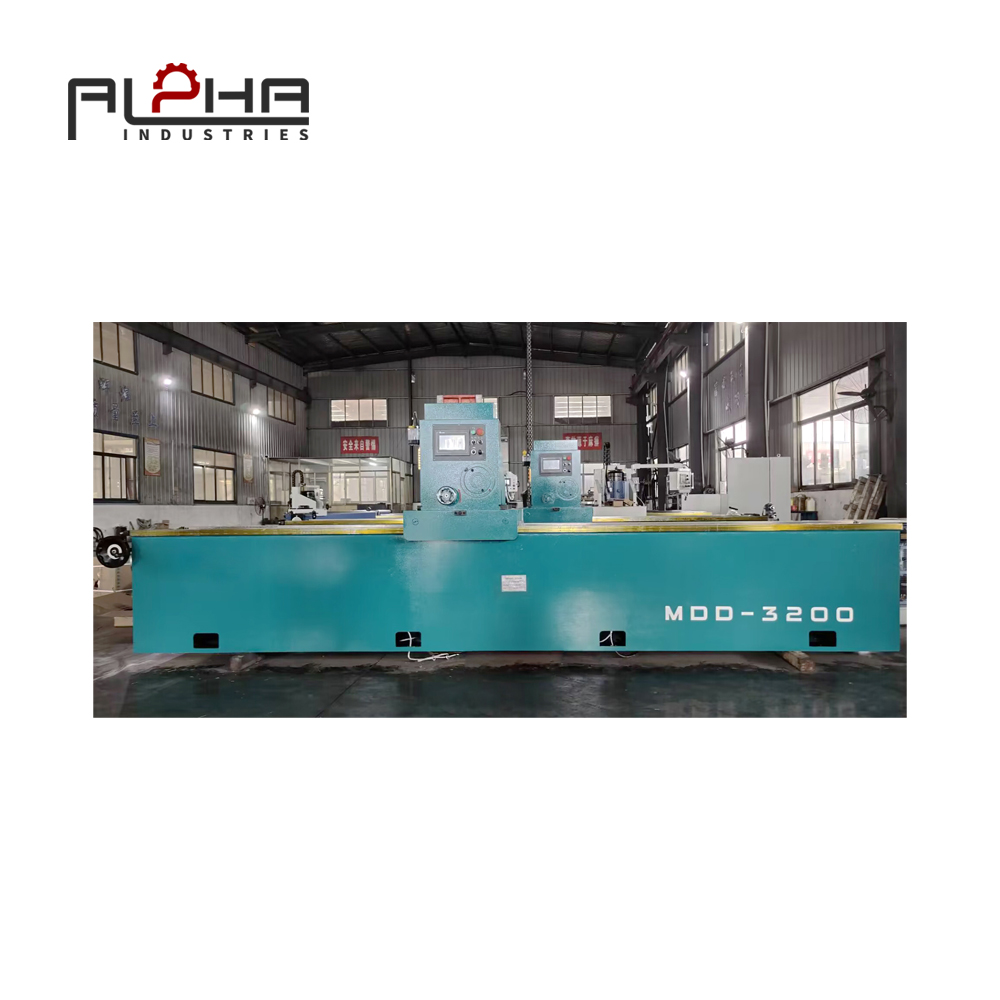

| Wind Energy | Large module gear cutting for turbine gearboxes |

Alpha’s versatility across sectors demonstrates its commitment to universal gear production precision.

Integration with Industry 4.0

Alpha’s Gear Hobbing Machines are fully compatible with Industry 4.0 smart manufacturing systems.

Features include:

-

Real-Time Data Monitoring

-

Tool Life Prediction Algorithms

-

Networked Maintenance Alerts

-

Energy Efficiency Tracking

This digital connectivity allows predictive diagnostics and adaptive process optimization—ensuring maximum uptime and cost savings.

Sustainability and Energy Efficiency

Alpha emphasizes eco-friendly manufacturing by incorporating:

-

Servo-driven feed systems to reduce idle energy consumption.

-

Efficient lubrication management for extended tool life.

-

Recyclable coolant filtration systems to minimize waste.

These innovations support global initiatives for sustainable and green gear production.

Why Choose Alpha Gear Hobbing Machine

High structural rigidity for stable precision

Digital synchronization for zero mechanical error

Adaptive hob wear compensation

Multi-cycle control for rough-to-finish hobbing

Smart connectivity for Industry 4.0 integration

Global service support and technical training

Alpha delivers not only machines—but complete gear manufacturing solutions built for future-ready factories.

FAQ

1. What types of gears can be produced using a Gear Hobbing Machine?

Alpha’s hobbing machines can produce spur, helical, worm, and spline gears with high accuracy and consistency.

2. How is the hob synchronized with the gear blank?

The hob and blank are digitally synchronized via a servo-driven electronic gearbox, ensuring precise angular alignment and eliminating backlash.

3. What is the accuracy level of Alpha Gear Hobbing Machines?

Depending on the model, Alpha achieves DIN Grade 6–7 precision and Ra 0.8 µm surface finish for production gears.

4. Can the machine handle large module gears?

Yes. Alpha offers heavy-duty models capable of cutting module sizes up to 20 mm for large industrial applications.

5. How does Alpha ensure consistent accuracy in mass production?

Through thermal compensation, automatic hob wear control, and real-time feedback, Alpha maintains micron-level consistency across production batches.

Conclusion

Precision in gear tooth forming is the foundation of efficient, silent, and durable transmission systems.

Alpha’s Gear Hobbing Machine combines robust mechanical design, intelligent control, and digital precision to help manufacturers achieve consistent high-quality gear production.

Whether producing small module precision gears or large industrial gear sets, Alpha ensures that every tooth reflects the company’s commitment to excellence.