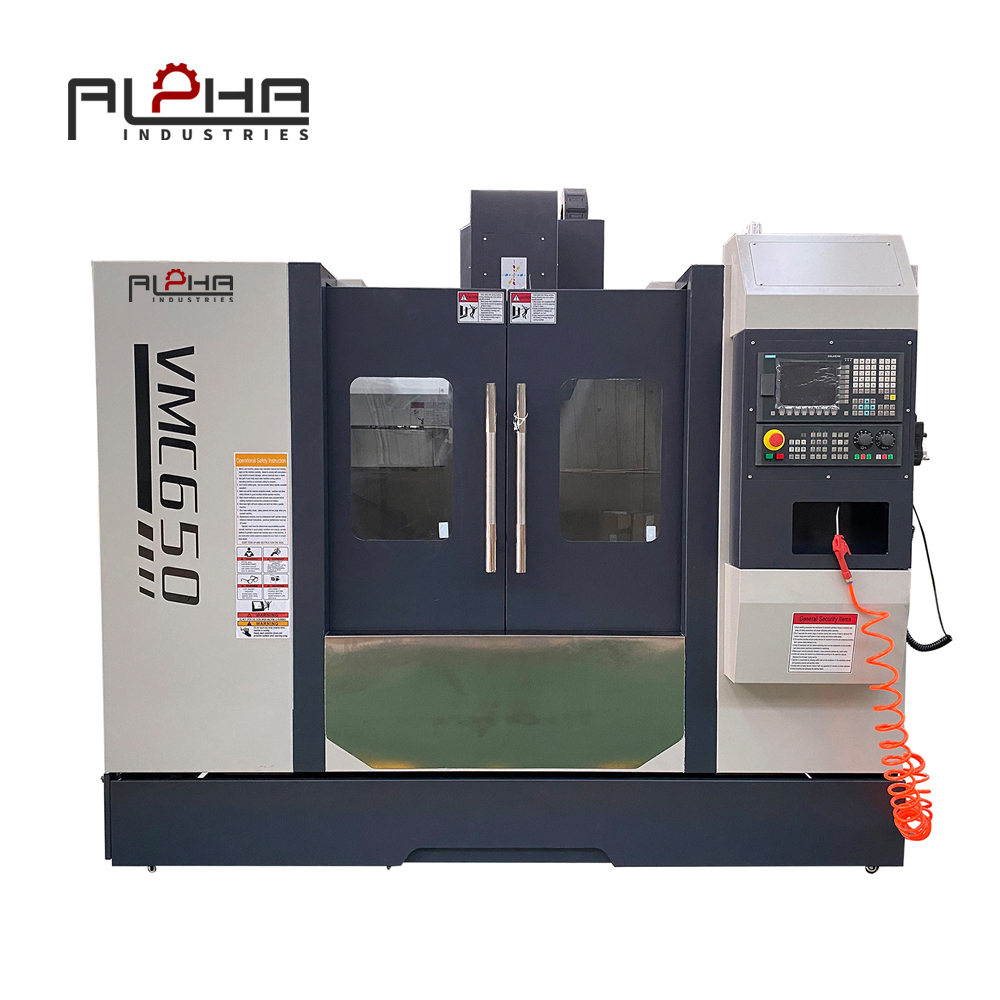

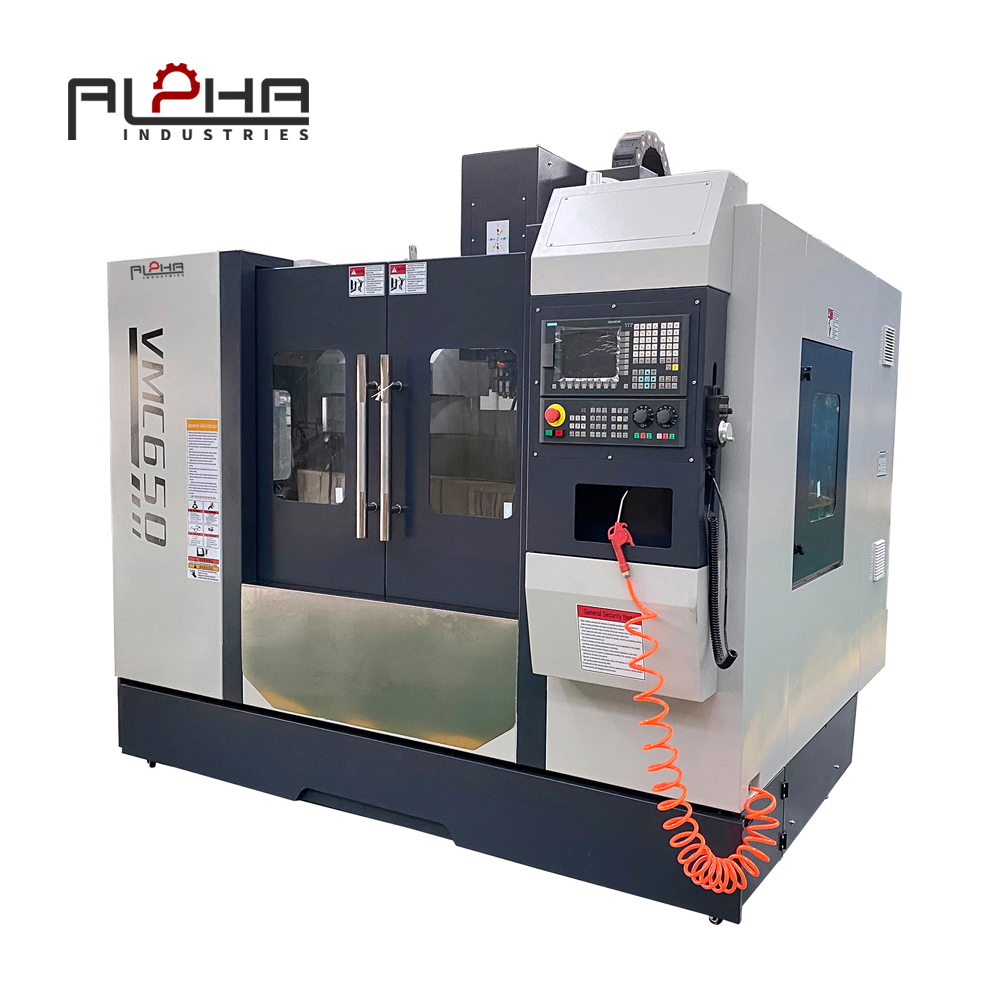

The VMC Series Smart Machining Center is at the forefront of precision manufacturing technology. Designed to meet the diverse needs of industries like aerospace, automotive, and medical devices, this advanced machining center combines efficiency, accuracy, and smart automation. With cutting-edge features and robust construction, the VMC Series ensures superior performance in high-demand manufacturing environments.

Key Features of the VMC Series Smart Machining Center

1. Unparalleled Precision and Efficiency

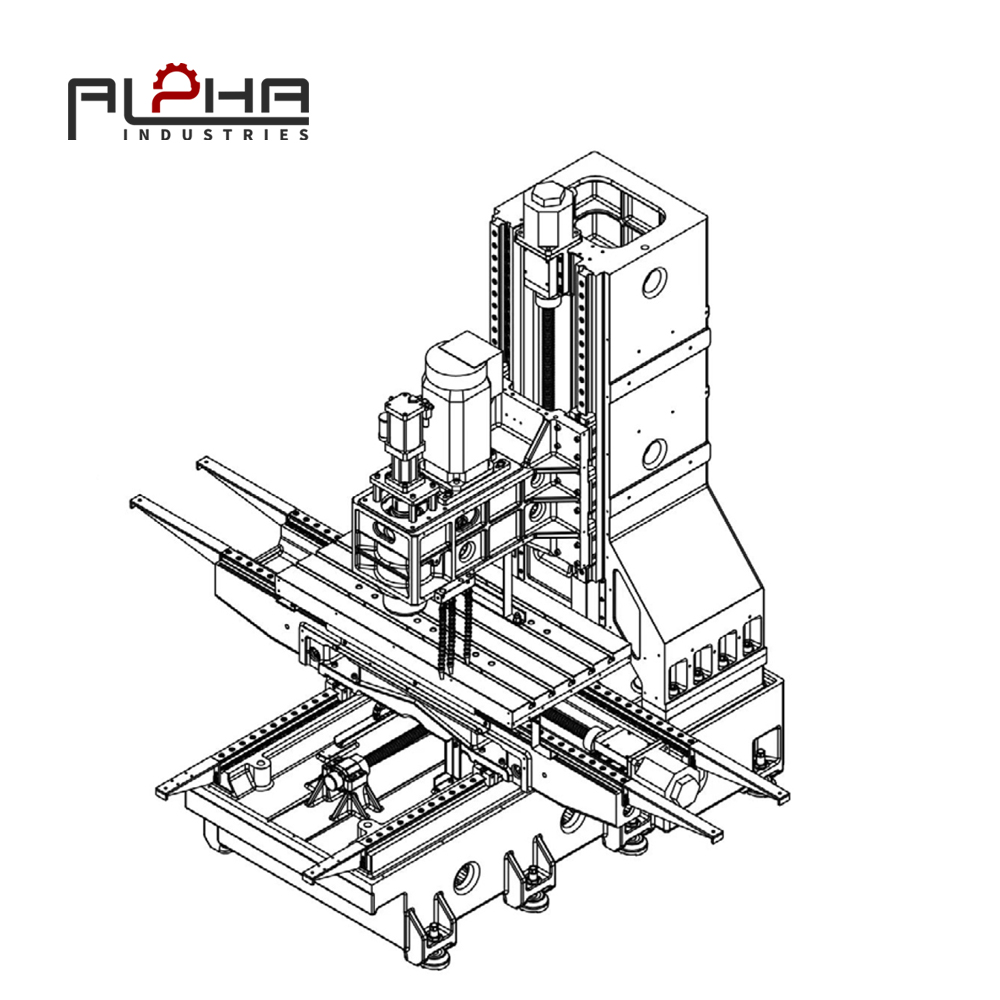

Equipped with high-speed spindles for smooth and precise cutting.

Advanced linear guideways reduce friction, enhancing tool accuracy.

Integrated sensors for real-time monitoring and feedback.

2. Smart Automation for Seamless Operation

IoT-enabled connectivity for remote monitoring and diagnostics.

Adaptive control systems for optimizing machining parameters.

Automated tool changers with high-capacity magazine options.

3. Durable and Versatile Design

Constructed with high-strength materials to withstand rigorous use.

Modular configurations allow customization for specific applications.

Ergonomically designed for user-friendly operation and maintenance.

4. Energy-Efficient Performance

Energy-saving modes to reduce power consumption.

High-efficiency motors and advanced cooling systems.

Applications of the VMC Series Smart Machining Center

Aerospace Industry: Precision machining for complex turbine blades and structural components.

Automotive Manufacturing: High-speed production of engine parts and transmission components.

Medical Device Fabrication: Crafting intricate surgical tools and implants with unparalleled accuracy.

Tool and Die Making: Creating molds, dies, and fixtures with tight tolerances.

Electronics Manufacturing: Precision machining of housings and connectors.

Advantages of Using the VMC Series

Improved Productivity: Reduced cycle times with high-speed operation.

Enhanced Accuracy: Minimal tool deviation ensures consistent quality.

Cost-Effectiveness: Energy-efficient systems lower operational costs.

Smart Integration: IoT and automation reduce human errors and downtime.

Eco-Friendly Operations: Sustainable design minimizes environmental impact.

FAQs

1. What distinguishes the VMC Series from traditional machining centers?

The VMC Series Smart Machining Center incorporates IoT connectivity, real-time monitoring, and adaptive control systems, unlike traditional machining centers, which rely on manual settings and lack smart automation features.

2. How does the VMC Series ensure precision in high-speed machining?

The VMC Series is equipped with high-speed spindles, linear guideways, and integrated sensors that work together to minimize errors and maintain tool accuracy during high-speed operations.

3. Can the VMC Series handle multi-material machining?

Yes, the VMC Series is versatile and capable of machining various materials, including metals, composites, and plastics, making it ideal for diverse industrial applications.

4. How does the VMC Series contribute to sustainable manufacturing?

The VMC Series features energy-saving modes, efficient cooling systems, and high-efficiency motors, reducing power consumption and environmental impact.

5. What industries benefit the most from the VMC Series?

Industries such as aerospace, automotive, medical devices, tool and die making, and electronics manufacturing gain significant advantages from the precision, efficiency, and versatility of the VMC Series.

6. What maintenance features does the VMC Series offer?

The VMC Series includes automated lubrication systems, real-time diagnostics, and modular components for easy maintenance and reduced downtime.

7. Is the VMC Series customizable?

Yes, the modular design of the VMC Series allows for customization to suit specific manufacturing requirements, including tool changers, spindle options, and worktable configurations.

Call to Action:

Looking for a reliable VMC Series? Contact us today to explore our extensive range of Precision Lathe Reliable Pergormance and find the perfect solution for your production needs.