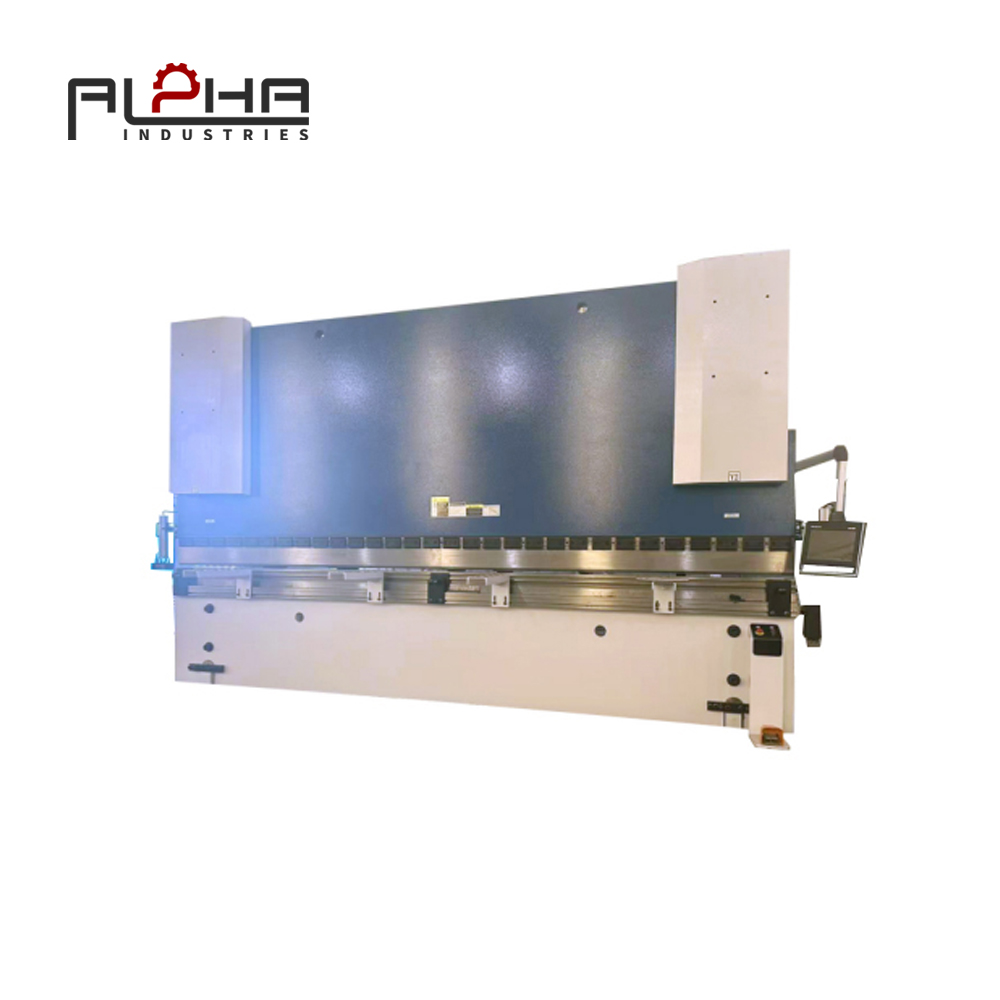

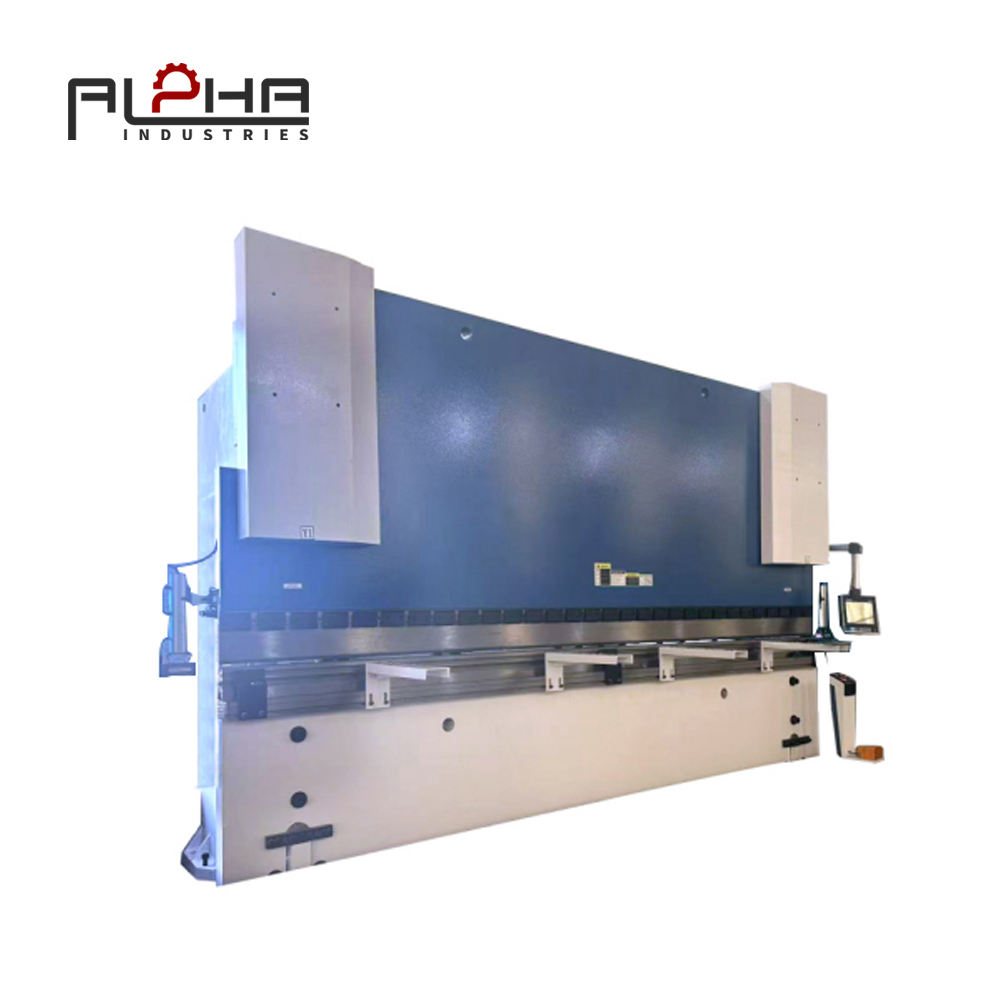

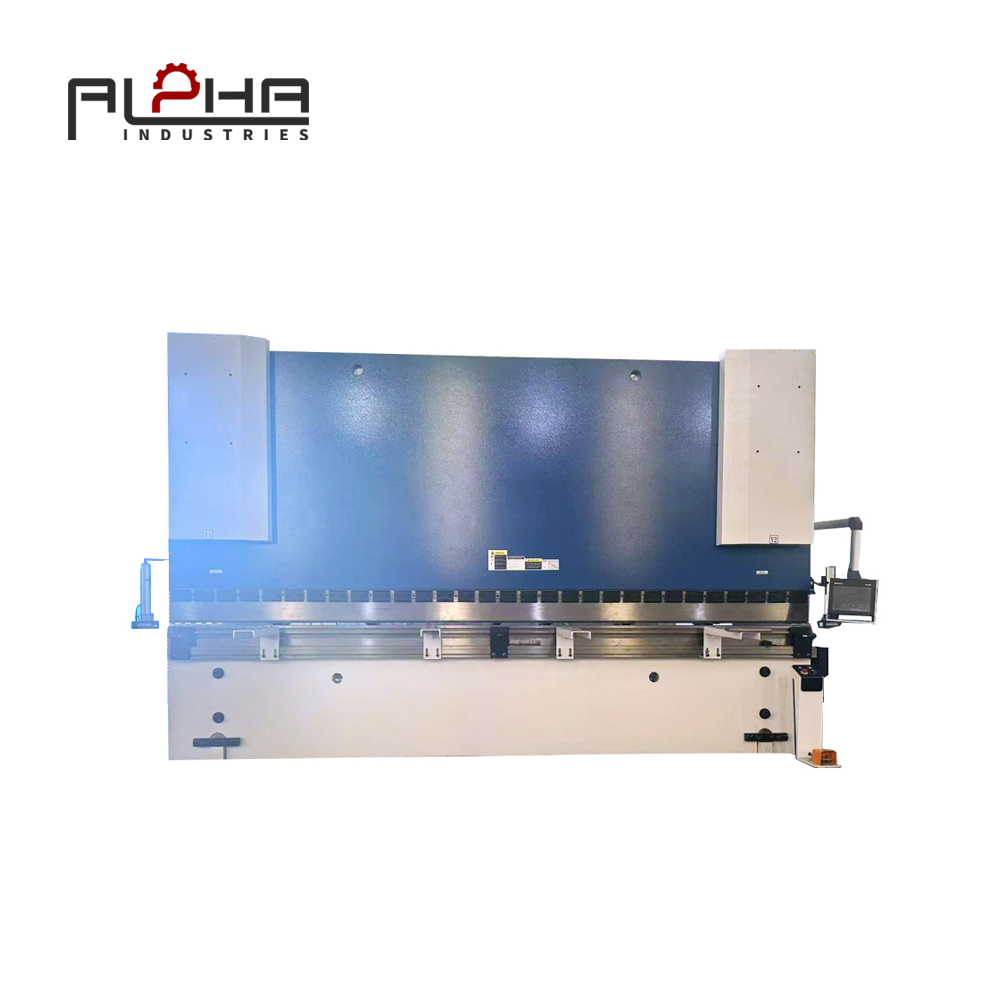

ALPHA Press Brakes are designed to deliver high-precision metal bending for a variety of industrial applications, including automotive, aerospace, and construction. With robust construction and advanced control systems, our press brakes ensure consistent bending angles, minimal material distortion, and efficient production processes.

Whether you are working with mild steel, stainless steel, or aluminum, ALPHA offers a range of Press Brake models to suit different thicknesses and bending lengths.

Key Features of ALPHA Press Brakes

-

High Precision Bending: Advanced hydraulic systems and optional CNC controls allow for accurate angle control and repeatability.

-

Robust Frame Construction: Heavy-duty steel frame reduces vibrations and maintains accuracy during long-term operations.

-

User-Friendly Interface: Intuitive control panels with programmable bending sequences improve productivity and reduce operator errors.

-

Flexible Tooling Options: Compatible with a wide range of dies and punches for various bending requirements.

-

Safety Features: Equipped with emergency stop, safety light curtains, and overload protection systems.

Learn more about ALPHA Press Brakes on our product page.

Common Problems with Press Brakes and Solutions

Even with high-quality machines like ALPHA Press Brakes, certain operational issues can occur. Understanding these problems and implementing solutions ensures optimal performance and longevity.

1. Inaccurate Bending Angles

Cause: Misalignment of the ram or worn tooling.

Solution:

-

Regularly calibrate the machine using angle gauges.

-

Inspect and replace worn punches and dies.

-

Check for hydraulic system leaks that may reduce pressure consistency.

2. Material Springback

Cause: Material elasticity causing it to partially unbend after pressing.

Solution:

-

Adjust bending allowance in the CNC program.

-

Use overbending techniques for difficult materials.

-

Select appropriate tooling radius for material thickness.

3. Hydraulic System Issues

Cause: Low hydraulic fluid, clogged filters, or pump malfunction.

Solution:

-

Maintain recommended fluid levels and replace fluid periodically.

-

Clean or replace hydraulic filters.

-

Schedule regular maintenance checks on the pump and valves.

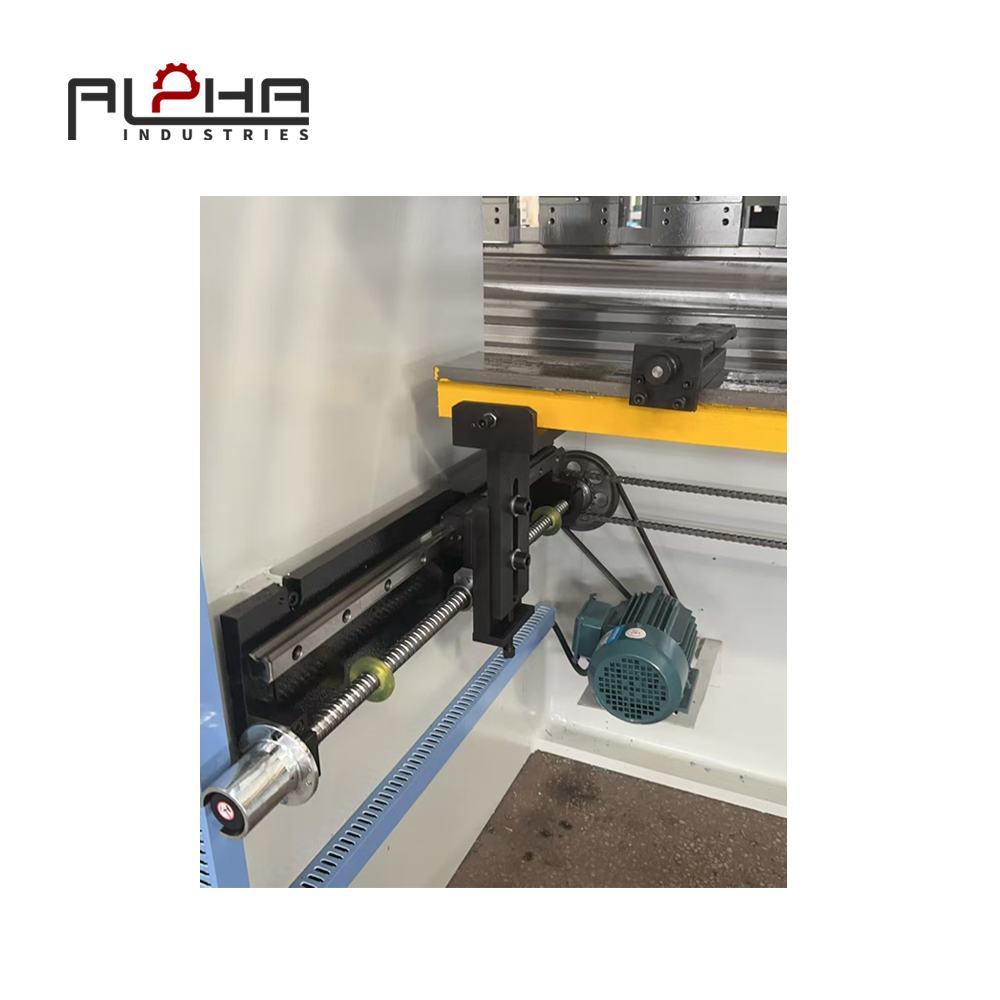

4. Machine Vibration and Noise

Cause: Loose components or insufficient lubrication.

Solution:

-

Tighten bolts and check the frame integrity.

-

Apply proper lubrication to all moving parts.

-

Inspect for worn bearings or guideways.

5. Operator Errors

Cause: Incorrect program input or improper material positioning.

Solution:

-

Provide comprehensive training for operators.

-

Utilize machine safeguards and program verification before production.

-

Implement a checklist for material setup and bending sequence.

Applications of ALPHA Press Brakes

ALPHA Press Brakes are widely used in:

-

Automotive panel bending

-

Aerospace component forming

-

Industrial sheet metal fabrication

-

Custom metal furniture manufacturing

Learn more about industry-specific applications in our Press Brake applications page.

Maintenance Tips for Long-Term Performance

To maximize the lifespan of your ALPHA Press Brake:

-

Perform daily inspections of tooling and hydraulic systems.

-

Keep the machine clean and free from metal dust and debris.

-

Schedule preventive maintenance every 3–6 months.

-

Ensure operators follow proper bending procedures.

Contact our team for maintenance support via ALPHA contact page.

Why Choose ALPHA Press Brakes

ALPHA Press Brakes combine precision, durability, and safety. With customizable configurations, flexible tooling, and advanced hydraulic systems, our machines offer reliable performance for any metal bending application.

Explore our full range of Press Brakes and bending machines to find the perfect solution for your production needs.

Frequently Asked Questions (FAQ)

Q1: What types of metals can ALPHA Press Brakes bend?

A1: Our press brakes can handle mild steel, stainless steel, aluminum, and other metal sheets of varying thicknesses.

Q2: How do I reduce springback during bending?

A2: Adjust the bending allowance, use overbending techniques, and select the correct tooling radius for the material.

Q3: How often should hydraulic fluids be changed?

A3: We recommend checking fluid levels daily and replacing hydraulic fluid every 6–12 months, depending on usage.

Q4: Can ALPHA Press Brakes handle large sheet sizes?

A4: Yes, we offer models capable of handling large sheets up to 6 meters in length.

Q5: Where can I get spare parts or technical support?

A5: Visit our contact page for spare parts, maintenance, and technical assistance.

To explore all features, specifications, and available models of ALPHA Press Brakes, download our product brochure here. This brochure provides detailed information to help you select the perfect press brake for your metal bending needs.