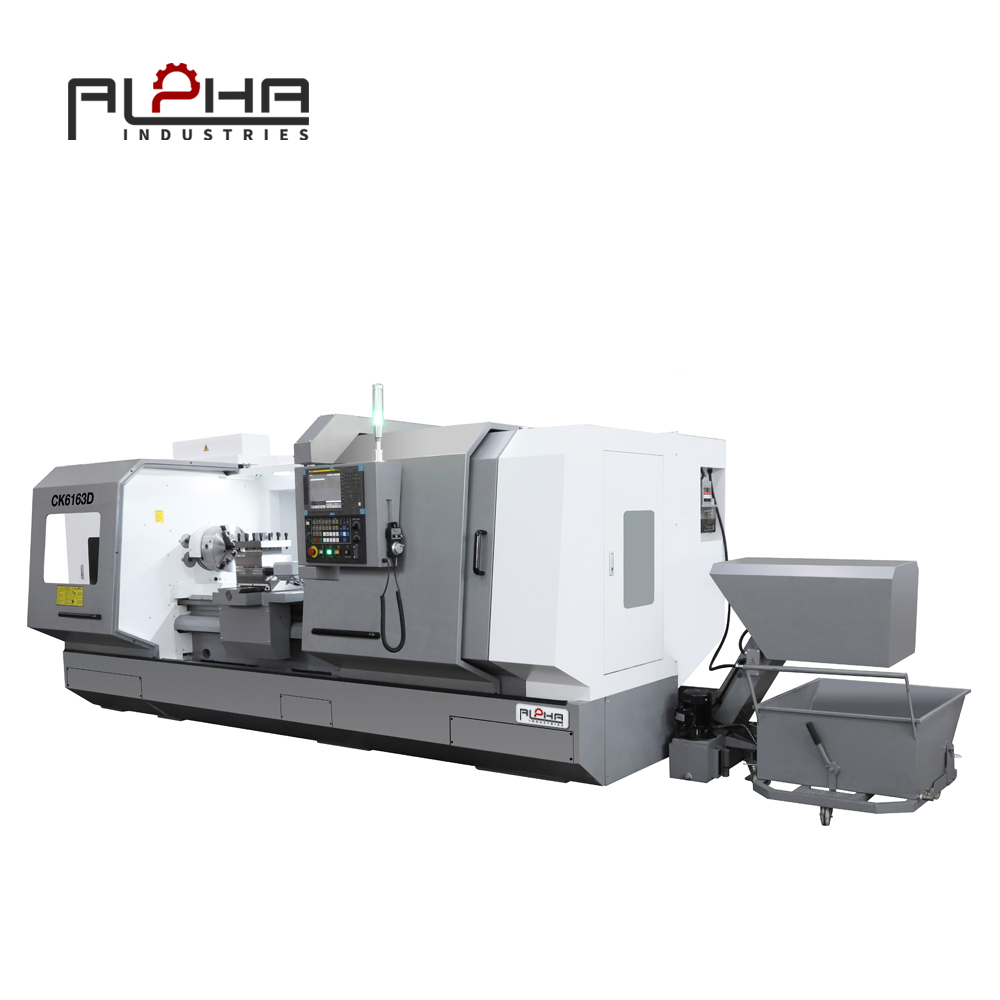

A shaft is a basic component in a mechanical system that transmits torque and rotation between key elements. Industry such as automotive, aerospace and heavy machinery require perfect diameters, precise diameters and excellent surface finishes. CNC lathes specially designed for shaft machining integrate advanced controls, enhanced support mechanisms and precise tools to meet these stringent requirements.

Technical requirements for shaft machining

Precision shaft machining requires:

-

Strict straightforward tolerance:It is crucial to prevent vibrations and ensure balanced rotation in dynamic applications.

-

Close diameter control:Ensure proper fit within the bearing and housing.

-

Top surface finish:Reduce friction and wear and extend assembly life.

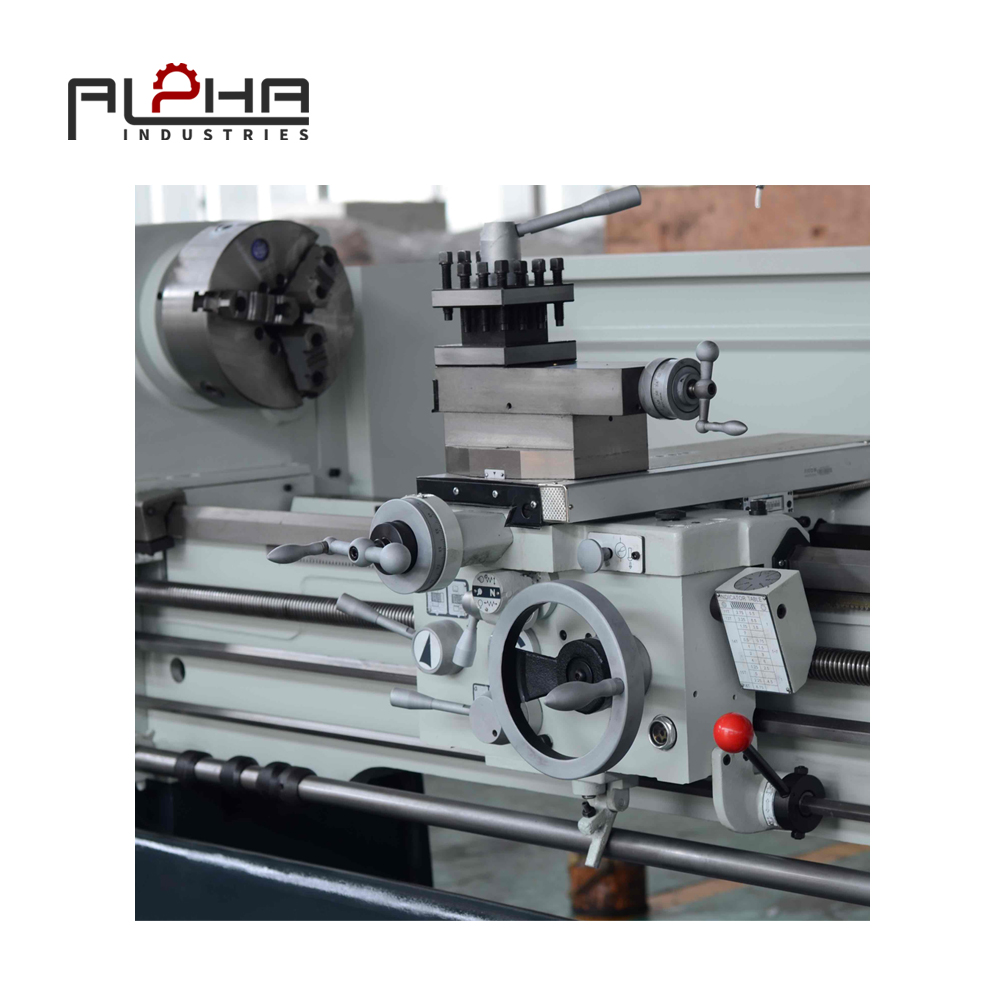

Key Features of CNC Lathes for Shaft Production

-

Extended bed length:Can accommodate shafts up to several meters while maintaining accuracy for the entire length.

-

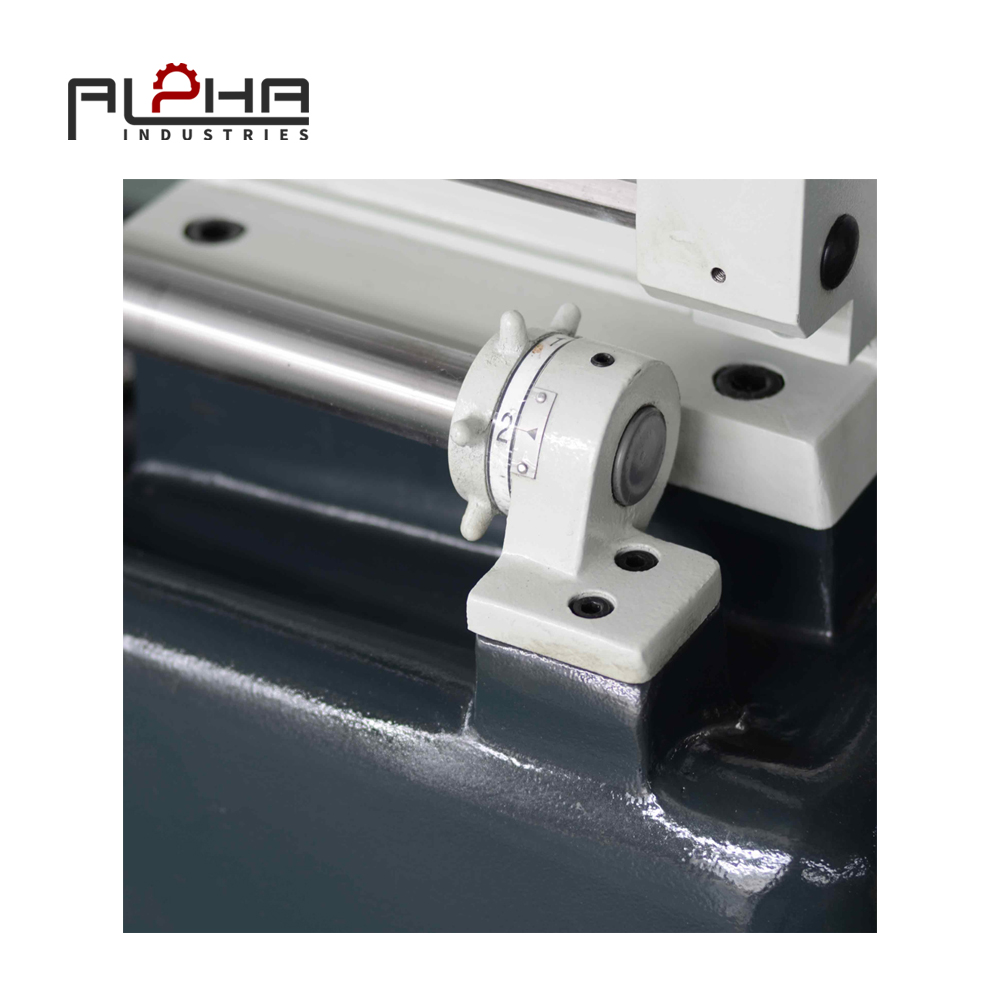

Stable rest and follower rest:Provides critical support to prevent long-term slender workpiece deflection during cornering.

-

High pressure spindle:Ensure stable cutting even at low rotation speeds required by heavy or dense materials.

-

Tail rod with hydraulic control:Accurately adjustable to maintain axial alignment, minimizing axial taper and thrust.

-

Real-time tools and Y-axis options:Enable milling of keyways, splines and other functions directly on the lathe.

The materials usually processed

-

Alloy steel shaft:Used for high-strength and fatigue-resistant applications in automobiles and aerospace.

-

Stainless steel:Used for corrosion resistance in marine or chemical environments.

-

Aluminum and Titanium:Lightweight applications where strength to weight ratio is critical.

-

Hardened steel:Used for wear-resistant surfaces in heavy industrial machinery.

Process Functions

-

Rough and complete turns:Batch material removal and fine finishing can be achieved in a single setup.

-

Thread cutting and groove:Functions such as threaded joints or oil grooves that are essential for rotating equipment.

-

Taper rotation:Generate a shaft with variable diameter for specific mechanical functions.

-

Surface roughness control:The RA is capable of transporting ≤0.4 μm, thereby ensuring minimal friction for operation.

Precision and quality control measures

-

Measurement probes during the process:Automatically verify diameter, concentricity and straightness during processing.

-

Laser measurement system:Provides continuous monitoring of long parts to detect any deviations in real time.

-

Dynamic balance preparation:Provides a boosted balance for high-speed shaft applications.

Industrial Applications

-

Automotive Industry:The drive shaft, cam shaft and crankshaft require tight dimensions and material specifications.

-

aerospace:Precision shafts for turbines, actuators and landing gear systems.

-

Heavy Duty Equipment:Industrial axis for power transmission in mining, construction and energy sectors.

-

Marine Engineering:Propeller shaft and rudder reserves require corrosion resistance and mechanical strength.

Advantages of CNC lathes in shaft machining

-

Unparalleled accuracy:Tolerances within ±0.005mm ensure accurate fit.

-

Consistent repeatability:CNC controls are capable of the same production in large batches.

-

Process efficiency:Settings are reduced with integrated turn, milling and drilling capabilities.

-

Reduce post-processing:Excellent surface surfaces minimize the need for secondary grinding or polishing.

in conclusion

CNC lathes tailored for shaft machining provide the accuracy, support and versatility required to generate critical rotating components. They provide the basis for high-performance machinery by ensuring that each shaft is straight, balanced and in-spec.

FAQ:

1. Why is straightforwardness in shaft machining crucial?

Straightness ensures smooth rotation without causing imbalance or vibration, which is critical to the performance and life of engines, turbines and rotating equipment.

2. Which support systems are helpful when machining the long axis?

Stable rest, self-plate rest, hydraulic tail is essential to prevent deflection and maintain diameter along the axis length.

3. Can CNC lathes produce keys and splines on the shaft?

Yes, CNC lathes equipped with real-time tools and Y-axis functions can be directly machined with key switches, splines and grooves, eliminating the need for auxiliary processes.

4. What level of tolerance can an exact axis achieve?

CNC lathes can reach tolerances up to ±0.005mm, suitable for applications where precise fit and minimal jump are critical.

5. Which material is best for high-performance shafts?

Alloy steel, stainless steel, titanium and hardened steel are usually used, selected according to the required strength, fatigue resistance and environmental conditions.