Why Bending Accuracy Defines CNC PRESS BRAKE SERIES Performance

In modern sheet metal fabrication, bending accuracy is no longer a competitive advantage — it is a fundamental requirement.

The CNC PRESS BRAKE SERIES from Alpha is engineered specifically to address the most critical challenge in bending operations: maintaining consistent, repeatable accuracy across varying materials, thicknesses, and batch sizes.

Rather than focusing broadly on machine versatility, this article dives deeply into one decisive technical factor:

👉 How intelligent control systems and mechanical precision work together to ensure micron-level bending accuracy in CNC press brakes.

Understanding Bending Accuracy in CNC Press Brake Machines

Bending accuracy in a CNC press brake is determined by the interaction of:

-

Ram positioning precision

-

Backgauge repeatability

-

Frame rigidity under load

-

Control system compensation algorithms

Even minimal deviation in ram depth or material springback can result in angle errors, rejected parts, and production delays.

The Alpha CNC PRESS BRAKE SERIES is designed with accuracy-first engineering at every stage.

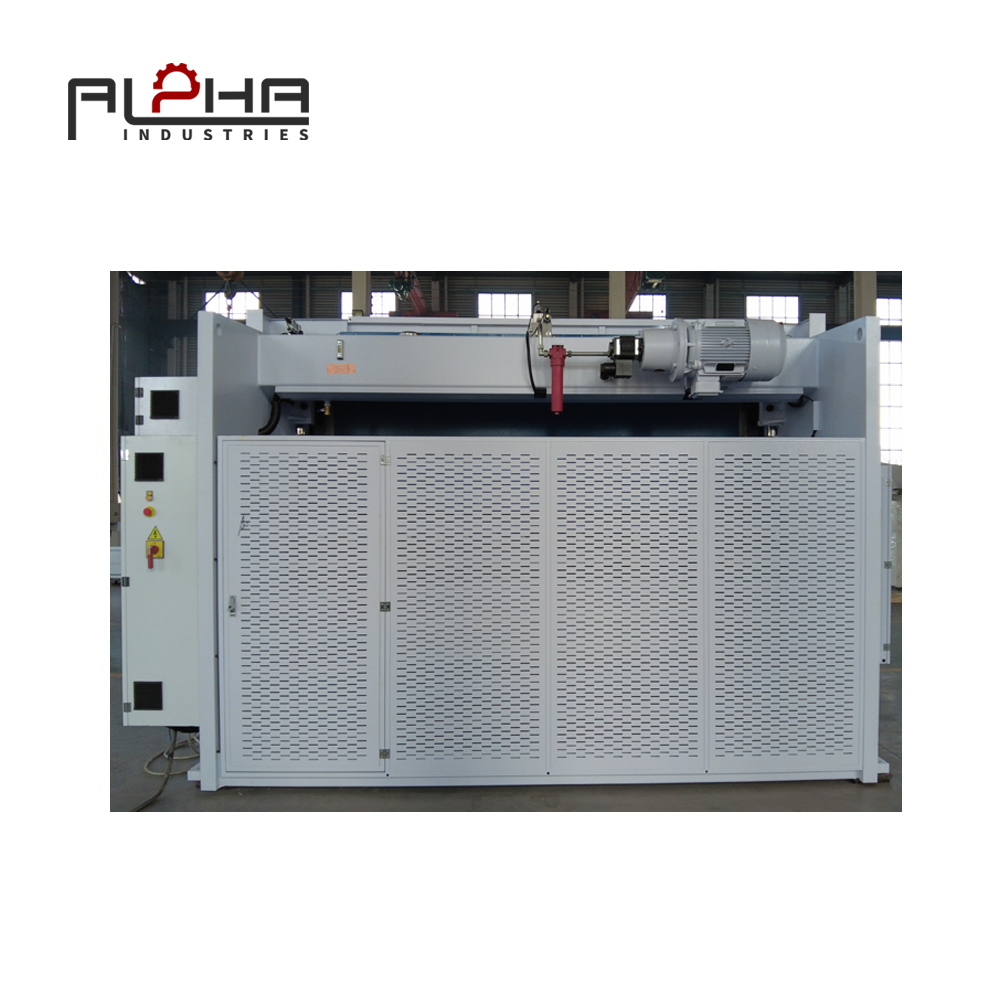

High-Rigidity Frame Design: The Mechanical Foundation of Accuracy

Accurate bending starts with structural stability.

Alpha CNC press brakes utilize:

-

Fully welded steel frames

-

Stress-relieved after welding

-

Finite element–optimized load distribution

This rigid construction minimizes elastic deformation during bending, ensuring that programmed angles remain consistent even under high tonnage.

Result:

✔ Stable bending angles

✔ Reduced recalibration

✔ Long-term accuracy retention

CNC Control System: The Brain Behind Precision Bending

At the heart of the CNC PRESS BRAKE SERIES lies an advanced CNC control system designed for precision bending.

Key control capabilities include:

-

High-resolution ram position feedback

-

Multi-axis synchronization (Y1/Y2/X/R/Z)

-

Real-time bending depth calculation

-

Automatic springback compensation

The CNC system continuously monitors and adjusts ram movement to achieve the exact bending angle required — even when material properties vary.

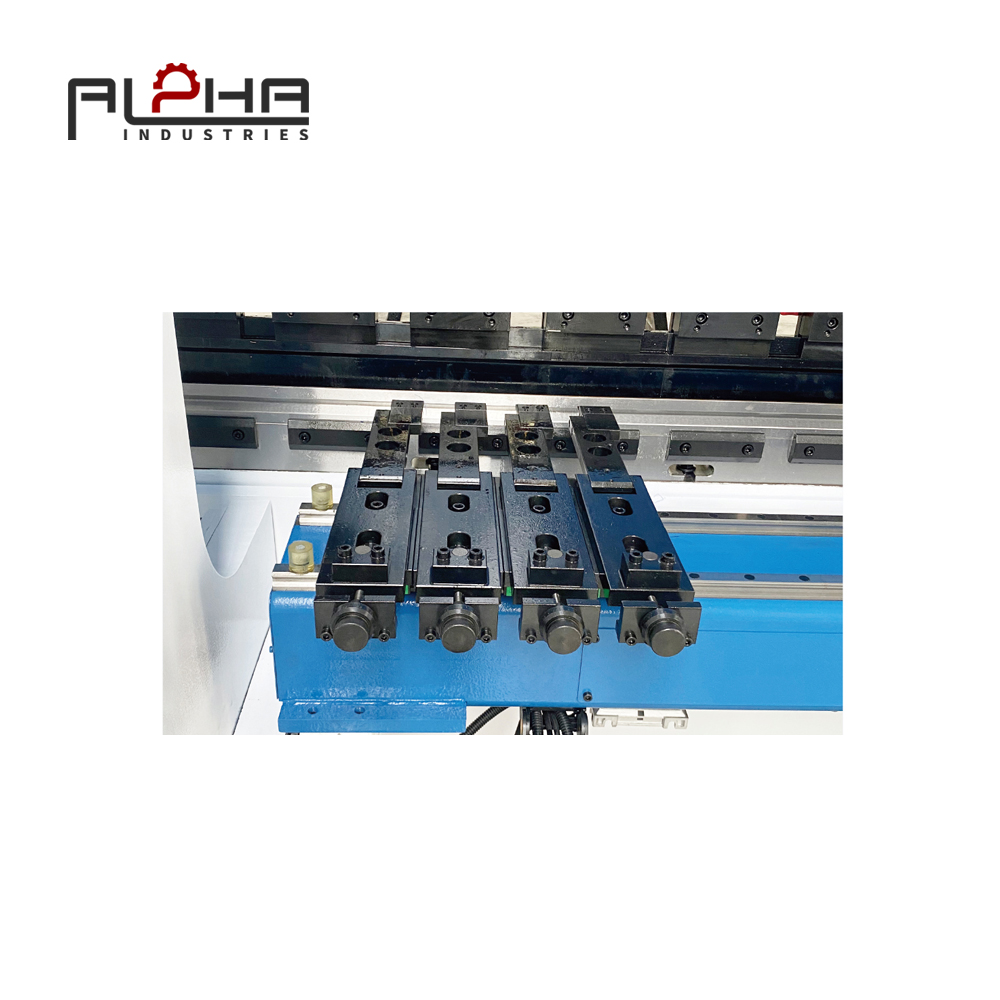

Ram Synchronization Technology for Parallel Accuracy

Uneven ram movement is one of the most common causes of angle deviation.

Alpha CNC press brakes implement precise Y1–Y2 synchronization, ensuring:

-

Parallel ram descent

-

Uniform pressure across the bending length

-

Identical angles on both ends of the workpiece

This is especially critical for long workpieces and high-precision applications.

Intelligent Crowning System for Angle Consistency

Material deflection increases with bending length. To counteract this, the CNC PRESS BRAKE SERIES integrates:

-

CNC-controlled crowning systems

-

Automatic compensation based on load and length

-

Uniform angle distribution across the entire bend

This ensures that parts bent at the center and edges maintain the same angle — a key requirement for high-end fabrication.

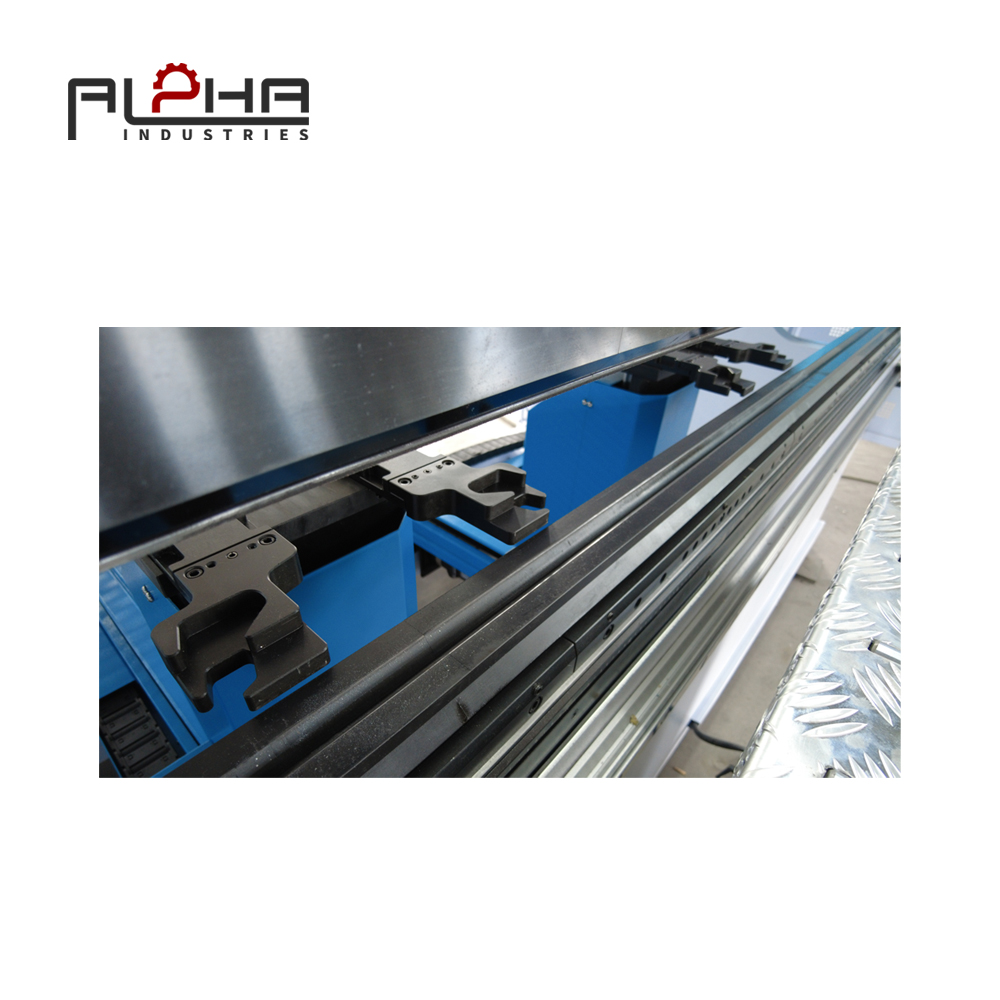

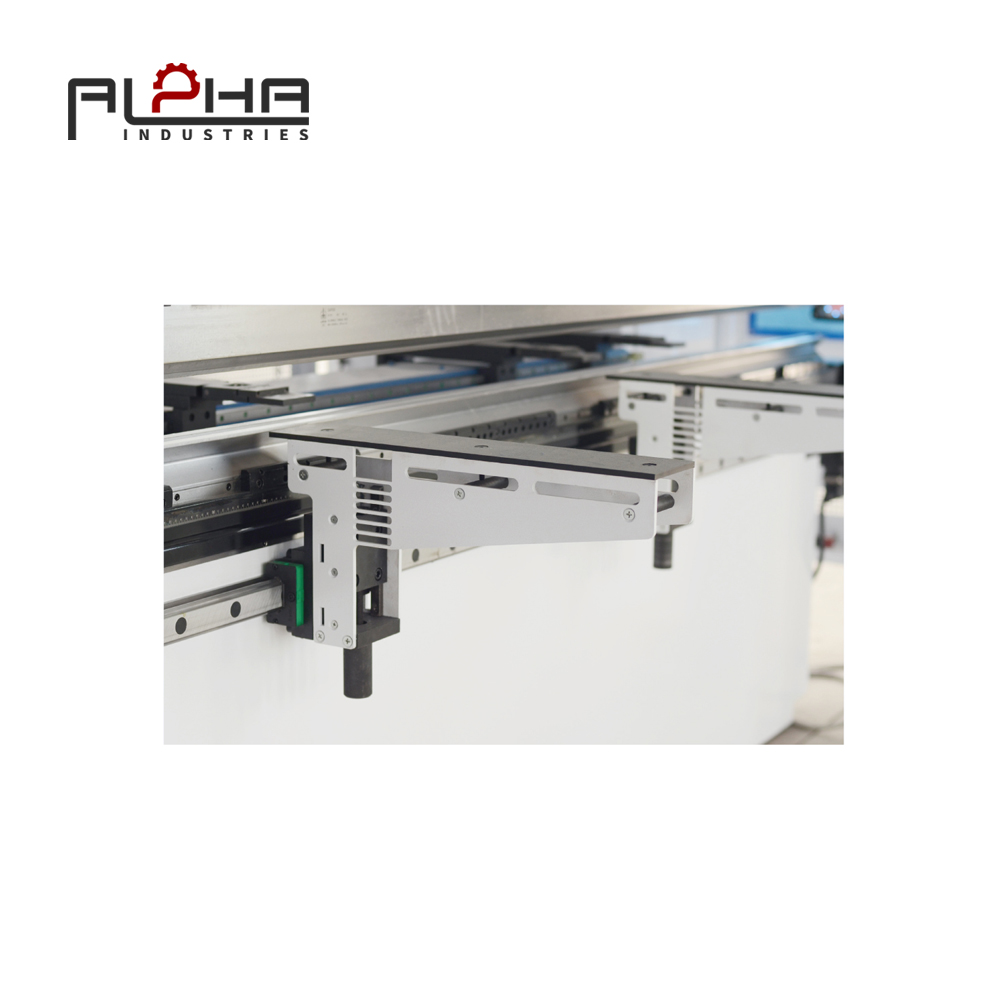

Backgauge Precision: Supporting Accurate Positioning

Bending accuracy is not only about angle — positioning accuracy is equally important.

Alpha CNC press brakes feature:

-

Servo-driven backgauge systems

-

High-precision linear guides

-

Ball screw transmission

This guarantees repeatable positioning for complex bending sequences and multi-step operations.

Adaptive Accuracy Across Different Materials

Different materials respond differently to bending force.

The CNC control system in Alpha press brakes allows operators to:

-

Input material type and thickness

-

Automatically adjust bending parameters

-

Reduce trial bends and setup time

This adaptability significantly improves first-piece accuracy and overall production efficiency.

CNC PRESS BRAKE SERIES for High-Precision Applications

Industries that rely heavily on bending accuracy include:

-

Electrical enclosures

-

Precision cabinets

-

Elevator components

-

Aerospace sheet metal parts

-

High-end architectural panels

The Alpha CNC PRESS BRAKE SERIES is specifically designed to meet these demanding accuracy requirements.

Reduced Scrap Rate Through Precision Control

Inaccurate bending leads directly to material waste.

By combining:

-

Rigid frame design

-

Intelligent CNC control

-

Automatic compensation systems

Alpha press brakes help manufacturers reduce scrap rates and improve yield consistency.

Long-Term Accuracy and Machine Stability

Accuracy is not just about day-one performance.

Alpha CNC press brakes are engineered for:

-

Long-term dimensional stability

-

Reduced wear-related deviation

-

Consistent accuracy over extended production cycles

This makes them suitable for continuous industrial use.

FAQ:

What makes a CNC press brake accurate?

A CNC press brake achieves accuracy through rigid frame construction, synchronized ram movement, intelligent CNC control, and real-time compensation systems.

How does a CNC control system improve bending accuracy?

It precisely controls ram depth, compensates for material springback, synchronizes axes, and adjusts parameters automatically during bending.

Why is crowning important in a CNC press brake?

Crowning compensates for bed deflection during bending, ensuring consistent angles across the full bending length.

Is CNC press brake accuracy affected by material type?

Yes, but advanced CNC systems allow operators to input material data and automatically adjust bending parameters for accuracy.

Why Choose Alpha CNC PRESS BRAKE SERIES for Precision Bending

Alpha focuses on precision-driven engineering, not generic machine assembly.

With the CNC PRESS BRAKE SERIES, users gain:

-

Reliable bending accuracy

-

Intelligent control integration

-

Industrial-grade mechanical stability

-

Lower operating errors

To explore more high-performance metal forming solutions from Alpha, visit:

-

👉 CNC Press Brake Machine Solutions

https://alpha-cnc.com/products/cnc-press-brake-series -

👉 Industrial CNC Machine Series

https://alpha-cnc.com/products/cnc-machine

Contact Alpha today to learn how our CNC PRESS BRAKE SERIES can elevate your bending accuracy and production quality.