What is a CNC Surface Grinder?

A CNC Surface Grinder is a precision machine designed to produce highly accurate flat surfaces on metallic and non-metallic workpieces. By combining a rotating abrasive wheel and a controlled worktable, CNC surface grinders can achieve micron-level flatness and parallelism.

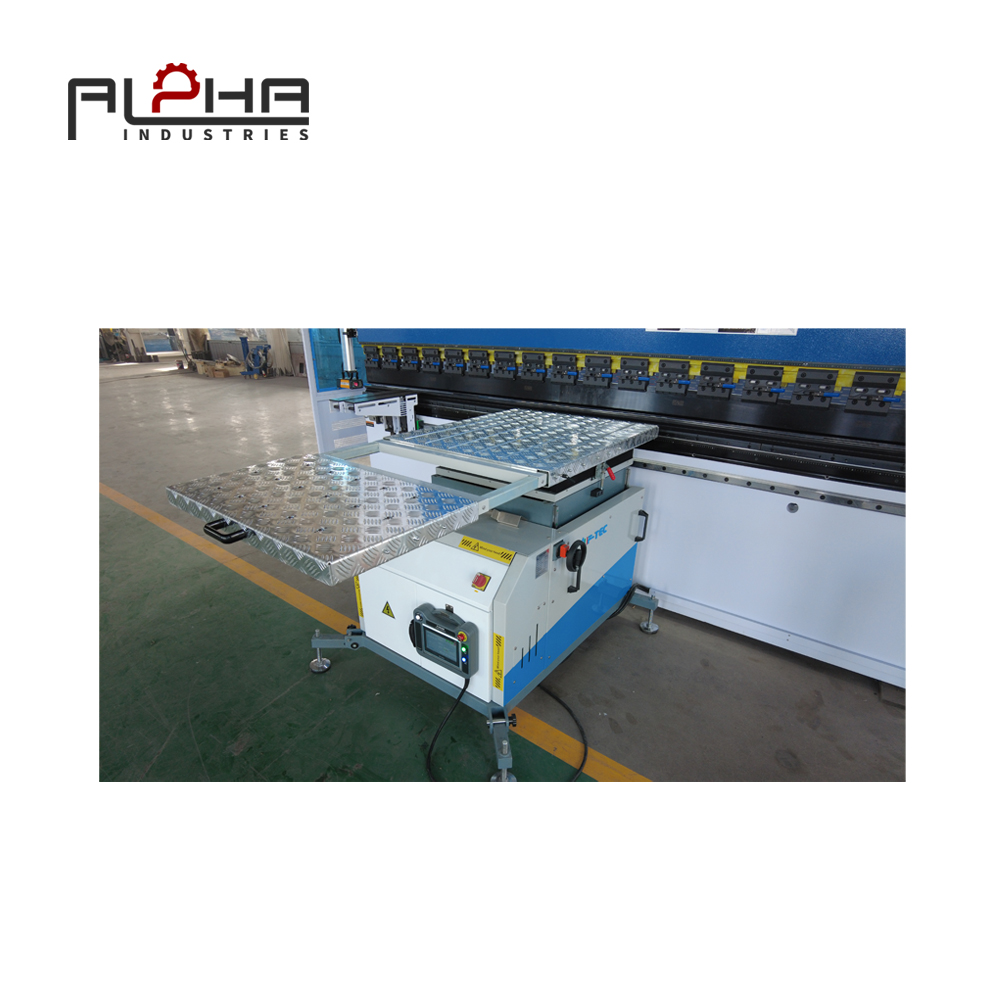

At Alpha, our CNC Surface Grinders integrate precision linear guides, servo drives, and thermal compensation systems, providing consistent high-accuracy results for industries including mold manufacturing, aerospace, automotive, and tool & die production.

Core Focus: Grinding Accuracy and Thermal Compensation

In precision surface grinding, temperature variations are the primary factor affecting accuracy. High-speed rotation of the grinding wheel generates heat, which can cause thermal expansion in the spindle, bed, and workpiece. This affects flatness, surface roughness, and dimensional tolerance.

Alpha addresses this with advanced thermal compensation and machine rigidity design, ensuring consistent micron-level precision throughout the grinding process.

1. Thermal Compensation System

Alpha’s CNC surface grinders feature real-time thermal monitoring sensors and compensation algorithms that adjust:

-

Table positioning

-

Spindle height

-

Wheel dressing parameters

Benefits:

-

Maintains surface flatness ±0.002 mm.

-

Reduces wheel wear by balancing heat effects.

-

Improves repeatability in long production runs.

2. High-Precision Spindle Design

The spindle is critical for achieving uniform material removal. Alpha utilizes:

-

High-speed angular contact bearings for low vibration.

-

Chiller-controlled spindle housing to maintain ±0.5°C stability.

-

Direct-drive spindle motors for smooth torque transmission.

This ensures consistent grinding forces, minimal deflection, and high surface finish quality.

3. Machine Structure and Rigidity

Alpha CNC Surface Grinders are built with stress-relieved cast iron beds and vibration-absorbing rib structures. Finite element analysis optimizes:

-

Table support

-

Column stability

-

Cross-slide rigidity

Result:

-

Reduced chatter during high-speed grinding.

-

Improved flatness across the entire workpiece.

-

Long-term geometric stability for industrial production.

4. Precision Linear Guides and Servo Control

Alpha integrates linear ways and ball screws with preloading, ensuring:

-

Smooth table movement

-

Accurate wheel positioning

-

Minimal backlash

The servo-driven table and grinding wheel axes support CNC path programming, enabling:

-

Multi-pass grinding with automatic depth adjustment

-

High-speed finishing without compromising accuracy

-

Reduced operator dependency

5. Automated Wheel Dressing and Surface Monitoring

For consistent grinding quality, Alpha includes:

-

Automatic diamond wheel dressing system

-

In-process surface height measurement

-

Adaptive feed rate control based on material hardness

This improves flatness consistency, extends wheel life, and optimizes cycle time.

Applications of Alpha CNC Surface Grinders

| Industry | Application |

|---|---|

| Mold Manufacturing | High-precision mold bases and inserts |

| Aerospace | Aluminum and titanium components finishing |

| Automotive | Engine blocks, precision brackets |

| Tool & Die | Grinding dies, jigs, and fixtures |

| Electronics | Precision metal plates and connectors |

Each application benefits from thermal compensation, spindle stability, and automated control, achieving high repeatability and minimal surface errors.

Energy Efficiency and Sustainability

Alpha CNC Surface Grinders incorporate servo-driven axes with regenerative braking and optimized cooling systems, which:

-

Reduce energy consumption by 20–25%

-

Minimize hydraulic or motor heat generation

-

Extend machine and wheel life

This ensures environmentally friendly and cost-efficient operation in high-volume production.

FAQ

Q1: What makes a CNC surface grinder different from manual grinders?

CNC surface grinders offer automated control, higher accuracy, repeatability, and reduced operator dependency.

Q2: How does thermal compensation improve grinding accuracy?

By monitoring spindle and table temperature in real-time, the system compensates for expansion, ensuring flatness and dimensional consistency.

Q3: What materials can Alpha CNC Surface Grinders process?

They can grind steel, aluminum, titanium, tool steel, and other metallic and non-metallic materials.

Q4: What industries benefit most from Alpha CNC Surface Grinders?

Mold, aerospace, automotive, tool & die, and electronics industries benefit from high-precision surface finishing and automated grinding.

Call to Action (CTA)

Enhance your production quality with Alpha CNC Surface Grinders — engineered for high-precision, thermal stability, and automated efficiency.

Explore Alpha CNC Surface Grinders

Learn more about Metal Processing Solutions