In advanced manufacturing, Electrical Discharge Machining (EDM) has become an essential process for achieving precision in metal parts that are difficult or impossible to machine by conventional methods. The EDM Machine operates by eroding conductive materials using controlled electrical discharges, ensuring exact geometry and exceptional surface finish quality.

Alpha’s EDM Machines are designed to provide superior accuracy, minimal tool wear, and consistent performance for industries requiring complex component manufacturing — including aerospace, automotive, mold, and die production.

The Core Principle of Electrical Discharge Machining

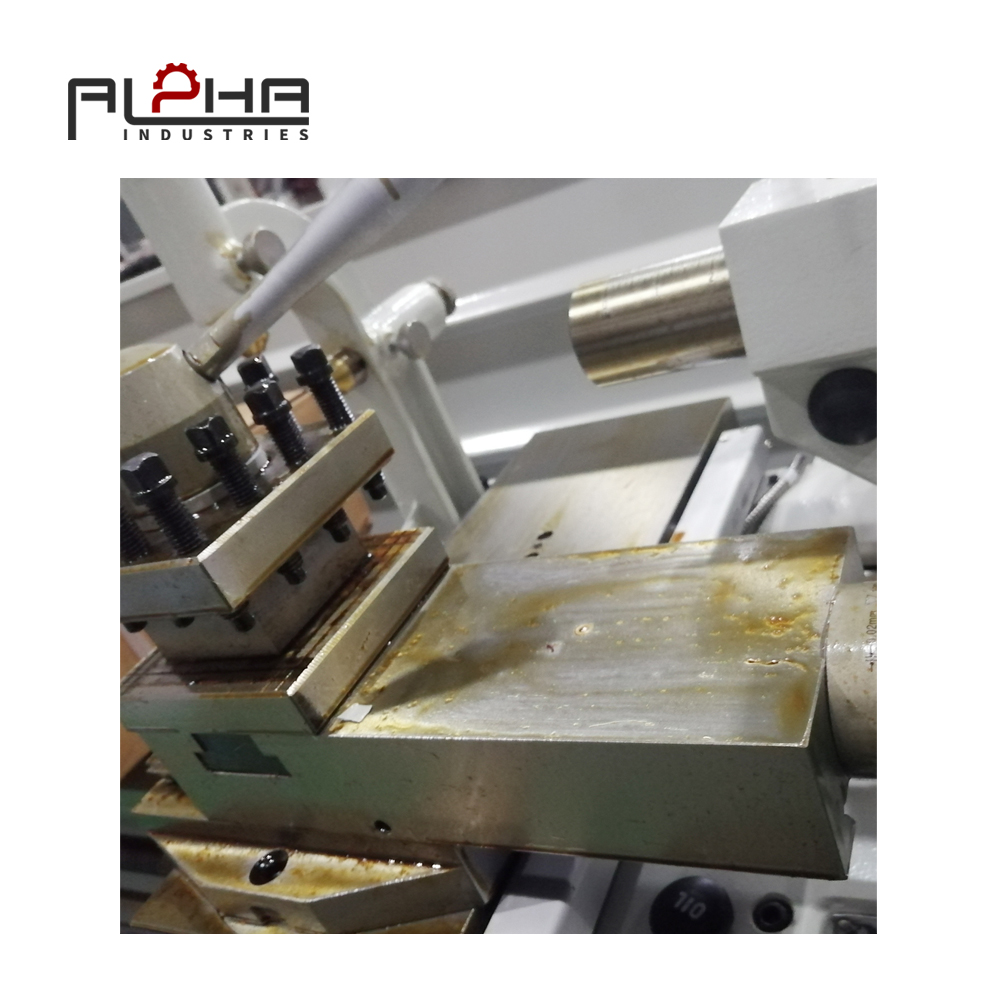

Unlike conventional cutting methods that rely on mechanical force, EDM removes material through a series of controlled electrical sparks between the electrode and the workpiece. These discharges generate localized heat, melting and vaporizing the metal at micro levels.

Each spark leaves a minute crater, and when controlled precisely, the cumulative effect results in a highly accurate shape with sub-micron-level surface roughness. This non-contact process allows machining of hardened steel, carbide, titanium, and other difficult alloys without inducing stress or deformation.

Precision Surface Finishing: The Competitive Edge

1. Micro-Level Accuracy

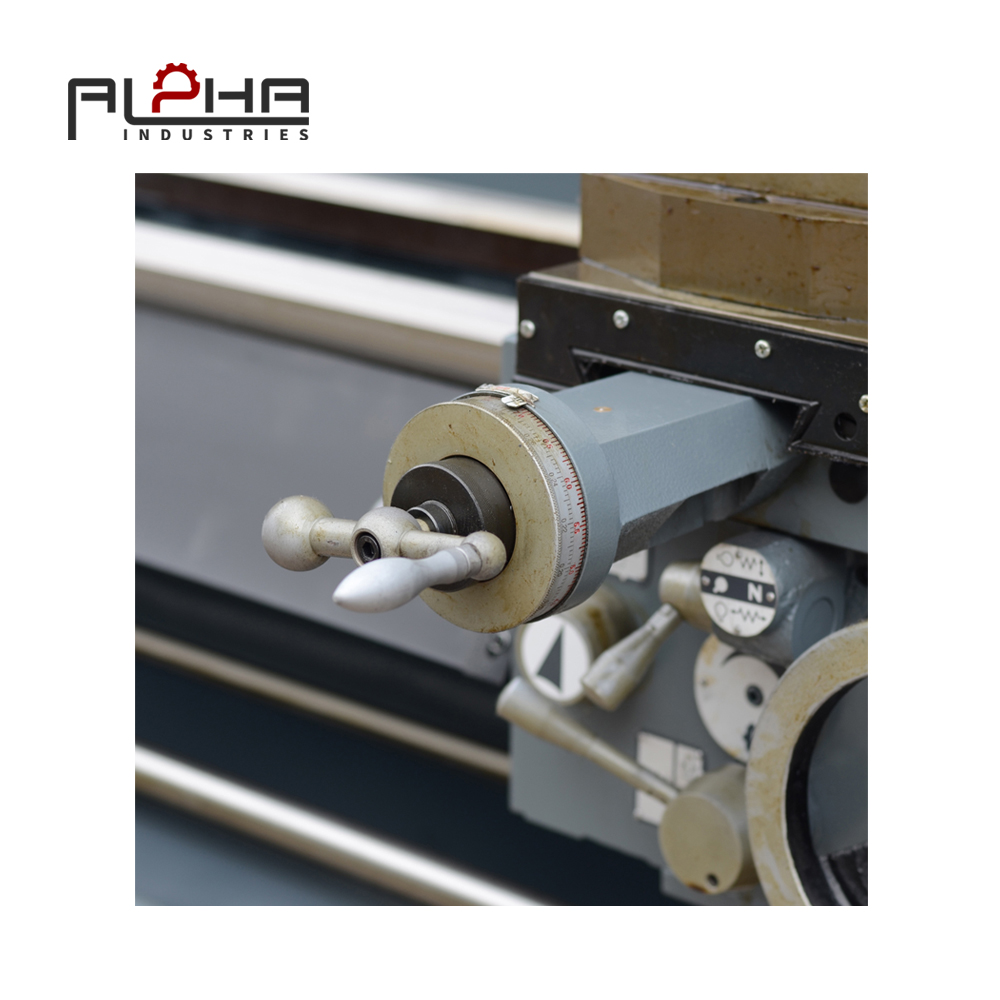

Alpha’s EDM Machine is engineered for dimensional accuracy within ±1µm. Its closed-loop servo control ensures stable spark generation, enabling mirror-like finishes (Ra ≤ 0.2 µm) on dies, molds, and intricate cavities.

2. Complex Geometry Realization

EDM technology enables sharp corners, fine ribs, and deep cavities that would be impractical using traditional cutting tools. This is crucial in injection mold and aerospace turbine component manufacturing, where geometric precision defines performance.

3. Stress-Free Machining

Since EDM is a non-contact thermal process, there are no cutting forces applied to the workpiece. This eliminates tool pressure, avoids microcracks, and maintains structural integrity — especially important for high-value alloy parts.

4. Superior Surface Integrity

With Alpha’s pulse energy control system, every discharge is optimized to minimize recast layers, resulting in clean, oxide-free surfaces. The process supports both roughing and fine finishing operations without additional polishing.

Types of EDM Machines and Their Applications

Wire EDM Machine

Wire EDM uses a continuously fed thin brass wire as the electrode to cut complex contours with extreme precision. Ideal for tool and die production, it delivers tight tolerances on 2D and 3D components.

Die Sinking EDM

Also known as Ram EDM, this method uses a shaped electrode to reproduce its form into the workpiece. It’s widely applied in mold cavity manufacturing, especially for intricate shapes in hardened materials.

Hole Drilling EDM

Used for producing micro-holes in turbine blades, fuel injectors, and medical components, this EDM type ensures high aspect ratio drilling with excellent repeatability.

Alpha’s Technological Advantages

| Feature | Description |

|---|---|

| High-Resolution Servo Control | Ensures spark stability and repeatable discharge patterns for consistent quality. |

| Adaptive Pulse Generator | Automatically adjusts discharge energy for material type and thickness. |

| Thermal Compensation System | Maintains dimensional accuracy under varying temperature conditions. |

| Automatic Tool Changer (ATC) | Reduces downtime and improves process automation. |

| Smart Monitoring Interface | Provides real-time machining data for predictive maintenance and process optimization. |

Alpha integrates Industry 4.0-ready architecture across its EDM Machine series, enabling data-driven manufacturing and remote diagnostics to improve uptime and productivity.

Applications Across Industries

-

Mold and Die Making: Producing complex injection and die-cast molds with ultra-fine finishes.

-

Aerospace Components: Machining of turbine blades, cooling holes, and superalloy components.

-

Medical Equipment: Precision shaping of surgical tools and implants.

-

Automotive Manufacturing: Fine finishing of transmission and fuel injection components.

-

Tooling Production: High-tolerance fixtures and punches with exceptional repeat accuracy.

Sustainability and Efficiency in EDM Processing

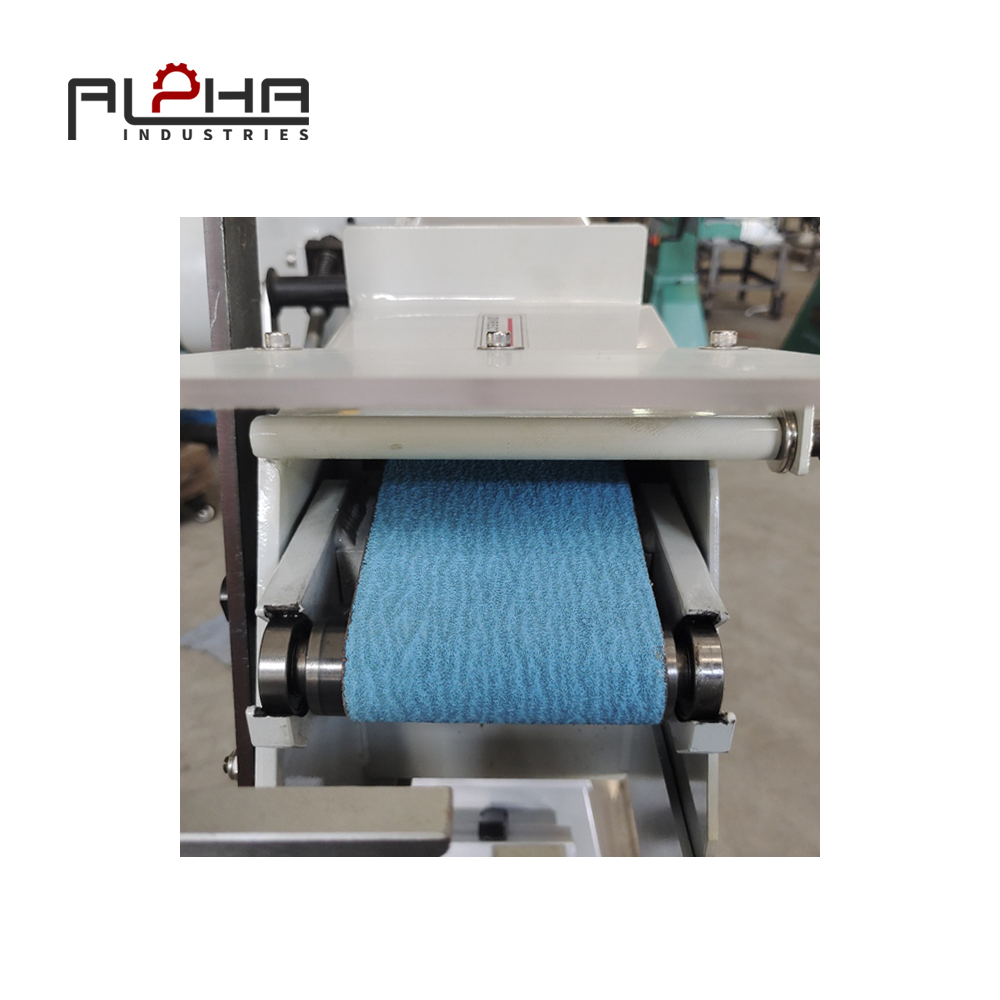

Modern EDM systems, including Alpha’s latest generation, utilize low-dielectric waste and energy-efficient discharge systems, reducing environmental impact and operation costs. With integrated filtration and eco-friendly dielectric fluids, Alpha supports green manufacturing initiatives without compromising performance.

Why Choose Alpha EDM Machine

-

Decades of experience in precision machining technology

-

Customizable configurations for various industry needs

-

Proven reliability in 24/7 high-demand production environments

-

Comprehensive after-sales support and global service network

Alpha’s EDM solutions reflect a deep understanding of precision manufacturing challenges, delivering machines that combine accuracy, efficiency, and innovation in every discharge.

FAQ

1. What materials can be machined using an EDM Machine?

EDM Machines can process any electrically conductive material, including hardened steel, tungsten carbide, titanium, copper, and Inconel.

2. How does EDM differ from traditional milling or grinding?

Unlike mechanical cutting, EDM uses electrical discharges, allowing non-contact machining of hard materials without mechanical stress or tool wear.

3. What is the typical surface roughness achieved by EDM?

With fine finishing settings, Alpha’s EDM Machine achieves surface roughness up to Ra 0.1–0.2 µm, suitable for optical mold applications.

4. Does EDM cause thermal damage to the workpiece?

No significant thermal damage occurs since the heat-affected zone is extremely shallow (micron-level), preserving metallurgical properties.

5. Can EDM be automated for high-volume production?

Yes. Alpha’s EDM systems include robotic integration and adaptive control, supporting fully automated, unattended operations.

Conclusion

Precision surface finishing defines the next era of metal processing, and the EDM Machine stands at the forefront of this evolution. Alpha’s advanced EDM technology enables manufacturers to achieve complex geometries, superior finishes, and stress-free machining, positioning it as a key player in modern industrial innovation.