Overview: High-Efficiency Horizontal Machining

The Horizontal Machining Center (HMC) is designed for high-rigidity, multi-axis metal cutting, particularly suitable for large workpieces like engine blocks, gear housings, and structural frames. Unlike vertical machining centers, HMCs offer better chip evacuation, reduced tool interference, and higher stability for heavy-duty cutting.

Alpha HMCs focus on high productivity and dimensional accuracy, integrating advanced CNC systems, rigid castings, and high-speed spindles to handle complex industrial components.

The Core Challenge: Large Workpiece Machining

Machining large and heavy parts brings challenges:

-

Thermal deformation due to cutting heat

-

Tool deflection under high loads

-

Uneven material stress causing dimensional errors

-

Chip accumulation affecting surface finish and tool life

Alpha HMC solves these challenges with high-rigidity frames, linear guideways, and optimized tool paths, ensuring consistent precision for large batch production.

High-Rigidity Frame and Spindle System

Alpha horizontal machining centers are built with box-type cast steel frames and stress-relieved structural components, providing:

-

Excellent resistance to vibration and deflection

-

Long-term geometric stability

-

High-speed cutting capability without sacrificing precision

The high-speed spindle supports heavy-duty cutting while maintaining minimal runout, enabling high-efficiency milling, boring, and drilling operations.

Multi-Axis CNC Integration

Alpha HMC integrates advanced CNC controls for:

-

X, Y, Z linear axes with high-resolution encoders

-

Simultaneous 4- or 5-axis machining for complex contours

-

Tool path optimization for material removal efficiency

-

Automated pallet handling for uninterrupted batch production

This automation reduces cycle time, improves repeatability, and minimizes operator error, critical for large part production.

Chip Management and Thermal Control

Horizontal machining centers naturally benefit from gravity-assisted chip evacuation, which is further enhanced by Alpha HMCs via:

-

Large coolant-through-spindle systems

-

Optimized chip conveyors

-

Dynamic temperature monitoring and compensation

These features prevent thermal distortion, tool wear, and surface defects, maintaining high dimensional accuracy over long production runs.

Applications in Heavy Industry

Alpha HMCs are widely applied in:

-

Automotive: engine blocks, transmission housings

-

Aerospace: landing gear, fuselage components

-

Industrial machinery: molds, presses, frames

-

Energy: turbine housings, generator components

-

Shipbuilding: structural steel components

They excel in large-part high-volume machining while maintaining tight tolerances.

Advantages Over Vertical Machining

| Feature | Horizontal Machining Center | Vertical Machining Center |

|---|---|---|

| Chip Removal | Gravity-assisted, efficient | Requires flood coolant/chip conveyors |

| Workpiece Stability | High, supports heavy parts | Lower stability for long workpieces |

| Tool Accessibility | Multiple sides without repositioning | Often requires re-fixturing |

| Productivity | Higher for batch production | Slower for large parts |

| Maintenance | Easier spindle cooling and lubrication | Complex with vertical orientation |

Alpha HMCs offer higher efficiency, better tool life, and lower downtime for industrial-scale operations.

Alpha Quality Control

Every Alpha HMC undergoes rigorous testing:

-

Laser straightness measurement for all axes

-

Full-load deflection simulation

-

High-speed spindle runout verification

-

Thermal compensation and CNC accuracy calibration

-

Continuous long-cycle machining tests

Ensuring each machine meets industrial precision and reliability standards.

FAQ

Q1: What is the main advantage of a horizontal machining center over a vertical one?

Better chip evacuation, higher rigidity, and more stable multi-axis machining for large parts.

Q2: What types of workpieces are suitable for HMC?

Engine blocks, gear housings, molds, turbine parts, and large structural components.

Q3: How does Alpha HMC maintain precision with heavy cutting loads?

Through a high-rigidity frame, linear guideways, dynamic thermal compensation, and high-precision spindle systems.

Q4: Can horizontal machining centers handle automated batch production?

Yes, pallet changers and CNC integration allow continuous, unattended production.

Q5: What industries benefit most from Alpha HMCs?

Automotive, aerospace, industrial machinery, energy, and shipbuilding.

For high-rigidity, high-efficiency, large-part machining, Alpha Horizontal Machining Centers are the ideal solution.

👉 Explore more Alpha Metal Processing Equipment:

-

CNC Lathe Slant – High-precision turning solution

-

Vertical Machining Center – Multi-axis milling system

-

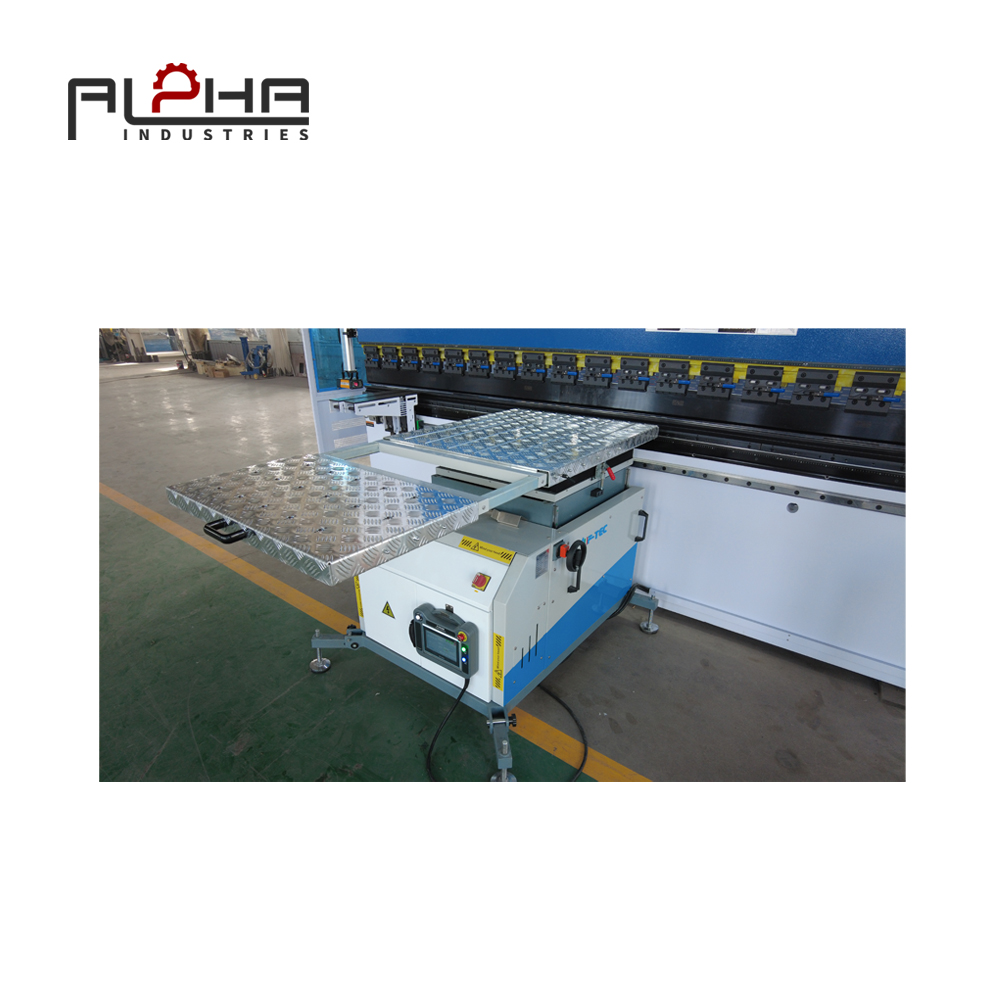

Press Brake Machine – Long-sheet precision bending

-

Drilling & Milling Machine – Dual-function machining

-

Surface Grinder – Ultra-fine finishing accuracy