High Precision Lathe with Advanced Spindle System | Alpha

A modern lathe is no longer defined only by its cutting capacity—it is defined by its spindle accuracy, thermal stability, rigidity, and consistent performance during long production cycles.

Why the Spindle System Determines Lathe Accuracy

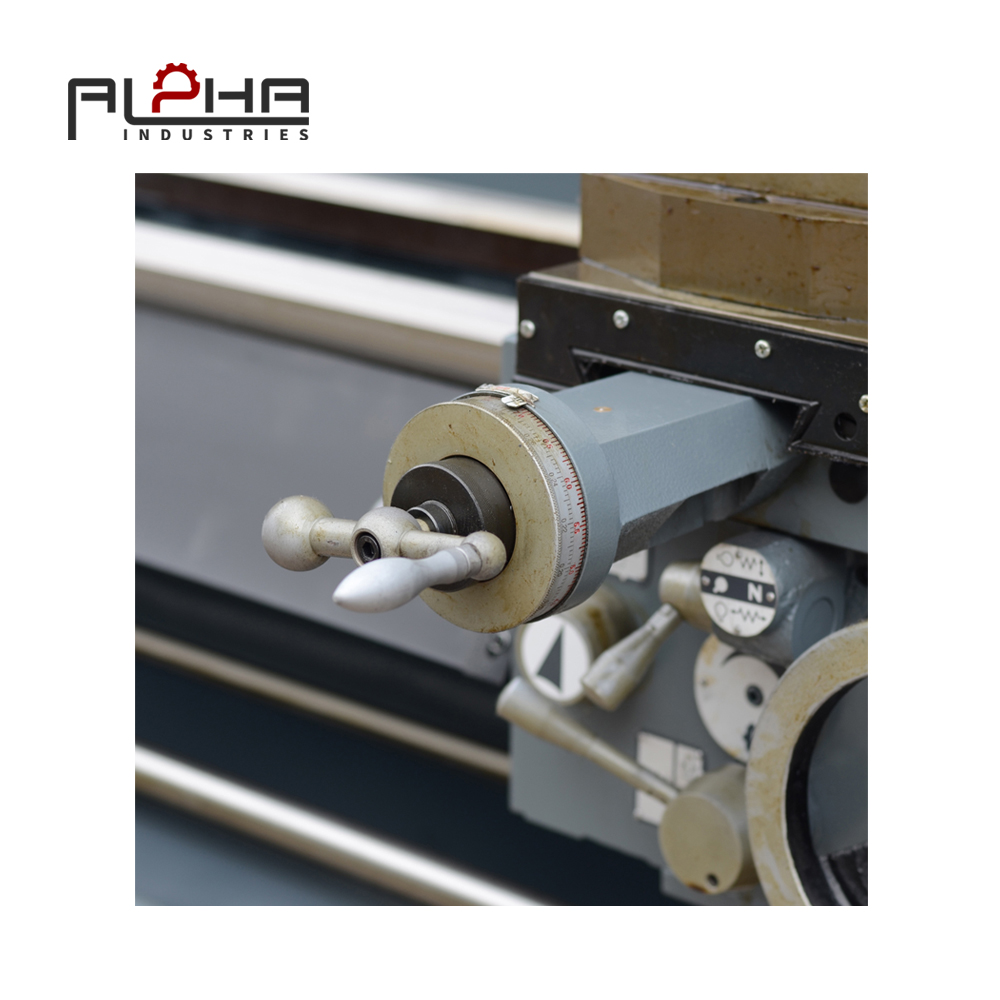

In any lathe, the spindle is the true heart of the machine. It controls the roundness, surface finish, concentricity, and dimensional tolerance of every part produced. A high-precision spindle must deliver consistent rotation even under cutting load, thermal stress, and prolonged operation.

Key performance factors include:

-

Spindle runout value (typically ≤0.005 mm for precision lathes)

-

Dynamic balance at high RPM, reducing vibration

-

Thermal deformation control, ensuring stable dimensional repeatability

-

Bearing structure, usually tapered roller bearings or angular-contact bearings

-

Lubrication system, ensuring long service life and smooth motion

Alpha integrates these engineering principles across its industrial lathe designs to ensure every turned component meets strict tolerance requirements.

Spindle Bearing Technology for Stable High-Speed Turning

The core of spindle performance lies in the bearing configuration, which must withstand radial and axial loads while maintaining accuracy. Alpha applies:

Optimized Angular Contact Bearing Arrangement

Angular contact bearings are preloaded and arranged to absorb thrust loads, reducing axial movement during heavy turning.

Wide-Spaced Support for Better Rigidity

A wider bearing span greatly reduces bending deformation, allowing the spindle to remain stable during interrupted cuts and deep-cut roughing.

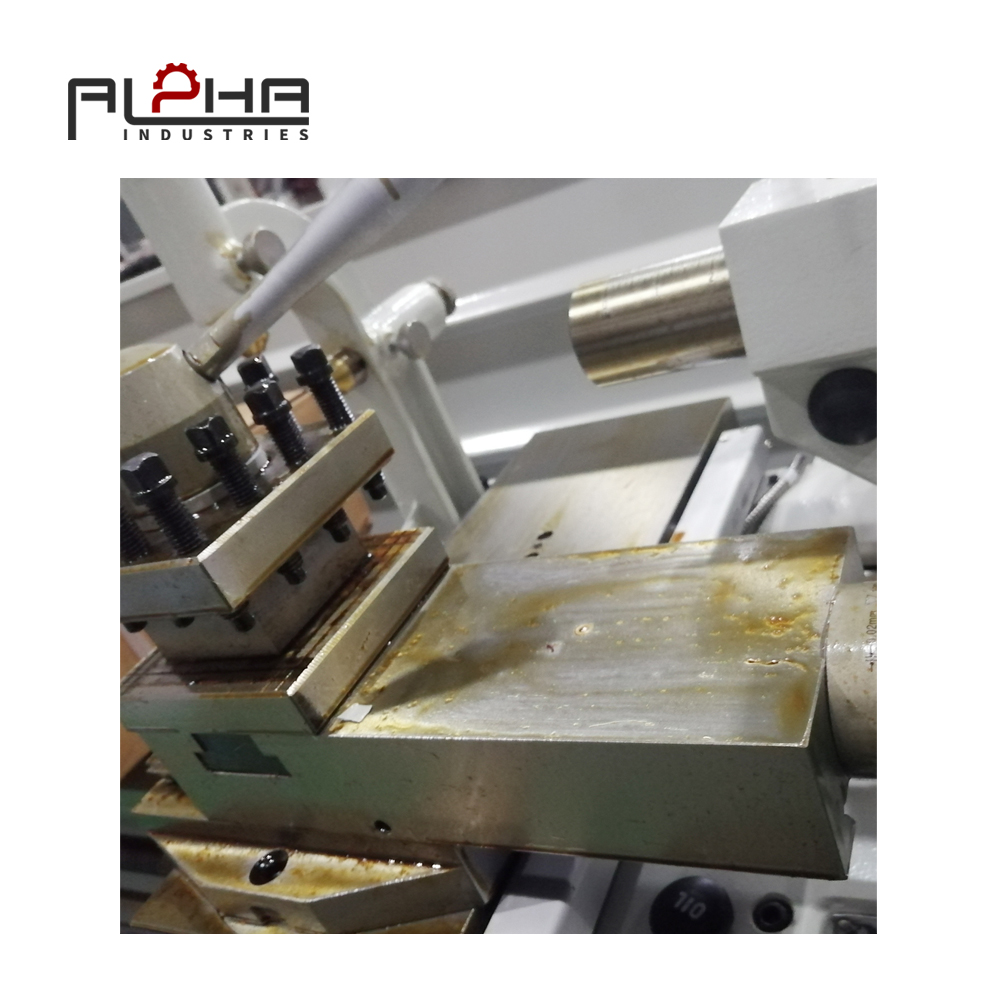

High-Precision Ground Bearing Seats

Bearing housings are machined in a single setup, ensuring concentric alignment between spindle centerline and headstock body.

These technical features ensure stable precision even at high spindle speeds, improving lifecycle, repeatability, and machining consistency.

Headstock Construction Enhancing Lathe Rigidity

A spindle can only perform as well as the headstock structure supporting it. Alpha designs its headstock with:

High-Strength Cast Iron for Maximum Dampening

Cast iron with uniform molecular structure minimizes vibration, reducing chatter marks on the workpiece surface.

Reinforced Headstock Ribs

Internal ribbing enhances stiffness to maintain spindle alignment during heavy-duty metal removal.

Thermally Balanced Layout

Heat is distributed away from the spindle centerline using cooling channels and symmetrical structural design, reducing thermal drift.

With higher rigidity, operators can apply larger feed rates and cutting depths, improving productivity without compromising part tolerance.

Spindle Lubrication and Cooling System for Long-Term Stability

A stable lubrication and cooling system is critical in maintaining spindle health.

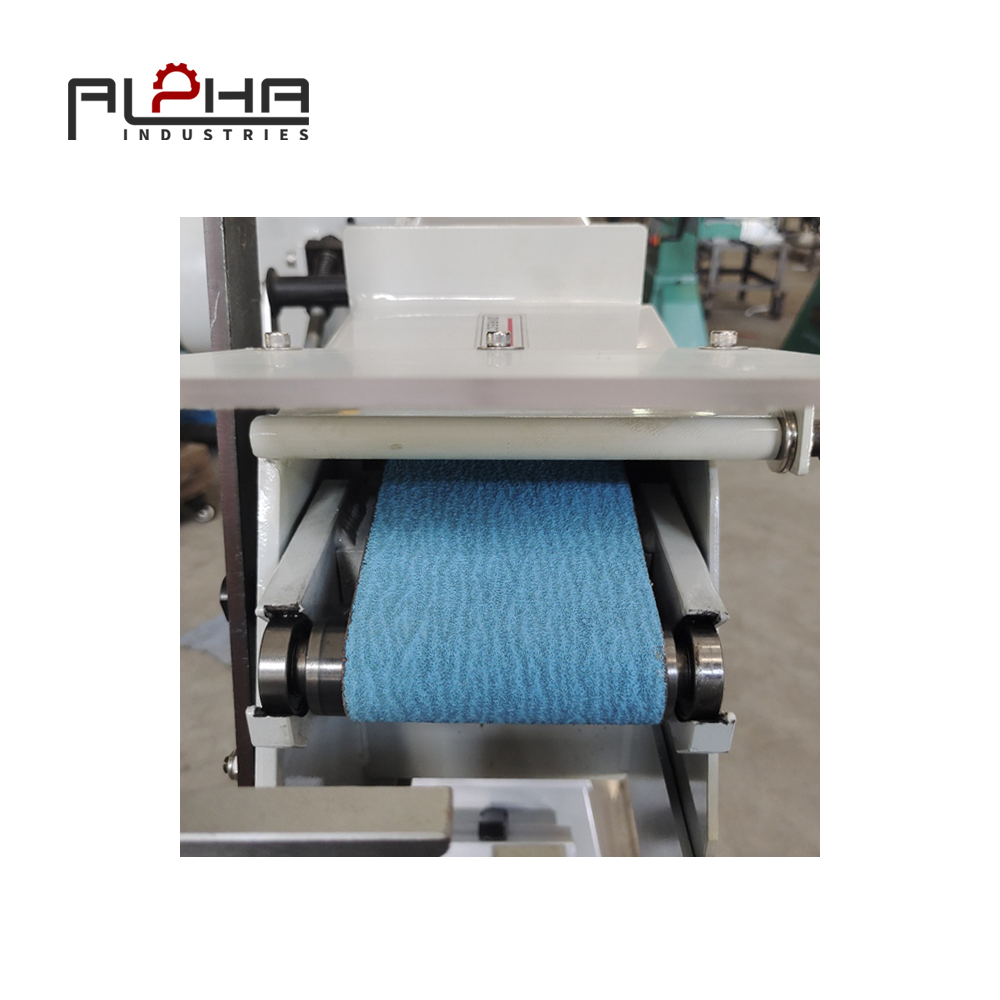

Oil-Air Lubrication

Provides micro-volume oil delivery and cooling air, reducing heat accumulation in bearings.

Circulating Cooling System

Prevents thermal deformation, allowing the spindle to maintain consistent performance throughout long machining cycles.

Low-Noise Operation

Stable lubrication reduces vibration, ensuring better surface finish and a quieter workshop environment.

This controlled thermal management significantly extends bearing lifespan and enhances accuracy.

How a Precision Spindle Improves Metal Turning Quality

A well-engineered spindle system directly affects:

-

Concentricity of shaft parts

-

Surface roughness (Ra ≤ 0.8 achievable with proper tooling)

-

Stability during long turning operations

-

Cutting efficiency and cycle time reduction

-

Tool life, because vibration is minimized

For industries requiring fine tolerances—automotive shafts, hydraulic components, fittings, pulleys, and precision bushings—the spindle system is the key differentiator between standard and high-end lathes.

What determines the accuracy of a lathe machine?

The accuracy of a lathe is primarily determined by its spindle system, including spindle runout, bearing configuration, headstock rigidity, and thermal stability.

Why is spindle runout important?

Spindle runout affects roundness, surface finish, and dimensional accuracy, making it a critical factor for precision turning.

How does headstock structure affect turning?

A rigid headstock minimizes vibration and thermal deformation, ensuring stable and accurate machining during roughing and finishing.

What improves lathe rigidity?

Cast iron frames, rib-reinforced headstocks, wide bearing spans, and precision-ground alignment surfaces enhance overall machine rigidity.

FAQs

What is the ideal spindle speed range for precision turning?

Precision lathes typically use spindle speeds between 40–2500 RPM, depending on material and part diameter.

How does spindle lubrication affect part quality?

Proper lubrication reduces heat and vibration, ensuring better dimensional tolerance and smoother surface finishes.

Is a heavier lathe more accurate?

Generally yes—heavier lathes offer better rigidity and vibration absorption, improving stability and accuracy.

What materials can a precision lathe machine?

Steel, alloy steel, brass, aluminum, stainless steel, cast iron, and heat-treated components can all be machined on a precision lathe.

Conclusion – Alpha Delivers High Precision Lathe Solutions

Alpha designs lathe machines with a clear engineering focus: a stable, accurate, and rigid spindle system that ensures reliable performance for demanding machining environments.

Whether you require fine-tolerance finishing or heavy-duty turning, Alpha’s spindle technologies guarantee consistent results and long-term durability.

-

Learn more: Vertical Machining Center

-

Explore: Press Brake Solutions