Introduction: The Importance of Precision in Modern Lathe Machines

In modern metal fabrication, precision defines performance. The lathe machine, one of the oldest yet most advanced machining tools, remains a cornerstone of high-accuracy production. Whether used for shaft manufacturing, thread cutting, or surface finishing, a precision lathe determines the quality and dimensional accuracy of the final product.

At Alpha, we design and manufacture high-performance lathe machines that integrate rigid construction, advanced spindle technology, and intelligent feed systems—ensuring perfect concentricity and repeatable precision even under heavy-duty cutting conditions.

Core Principle: High-Precision Turning Performance

1. Rigid Bed and Vibration Control

The foundation of precision lies in rigidity. Alpha’s lathe machine uses a one-piece cast iron bed with an optimized rib structure to minimize deflection. This robust base effectively absorbs vibrations during turning, ensuring that every cut maintains stable dimensional accuracy. The machine’s finite element analysis (FEA) design further optimizes stiffness-to-weight ratio for prolonged durability.

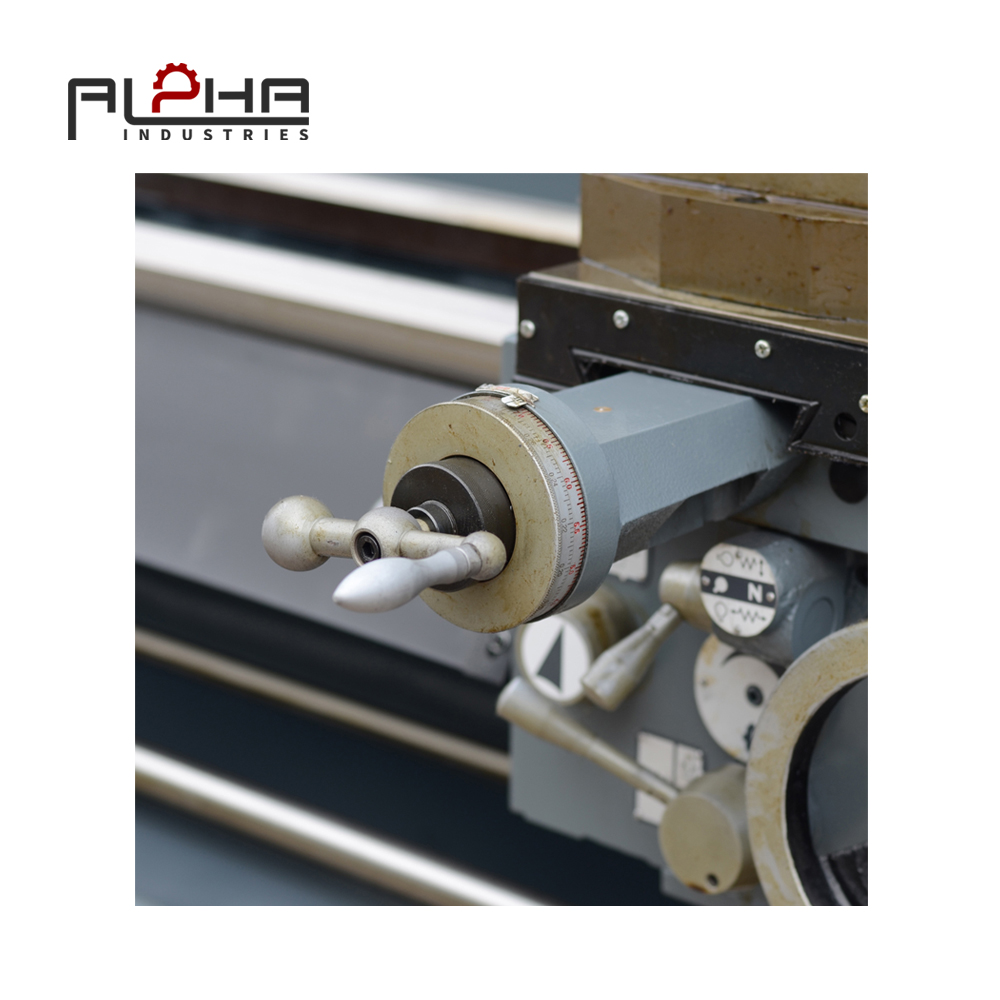

2. Precision Spindle Assembly

A high-performance spindle system is the heart of any lathe machine. Alpha’s spindle units are dynamically balanced and equipped with high-precision angular contact bearings. This design guarantees low runout—typically within 0.002 mm—and provides excellent radial and axial stiffness. The spindle drive system also allows variable speed control, making it adaptable to different materials such as carbon steel, stainless steel, aluminum, and brass.

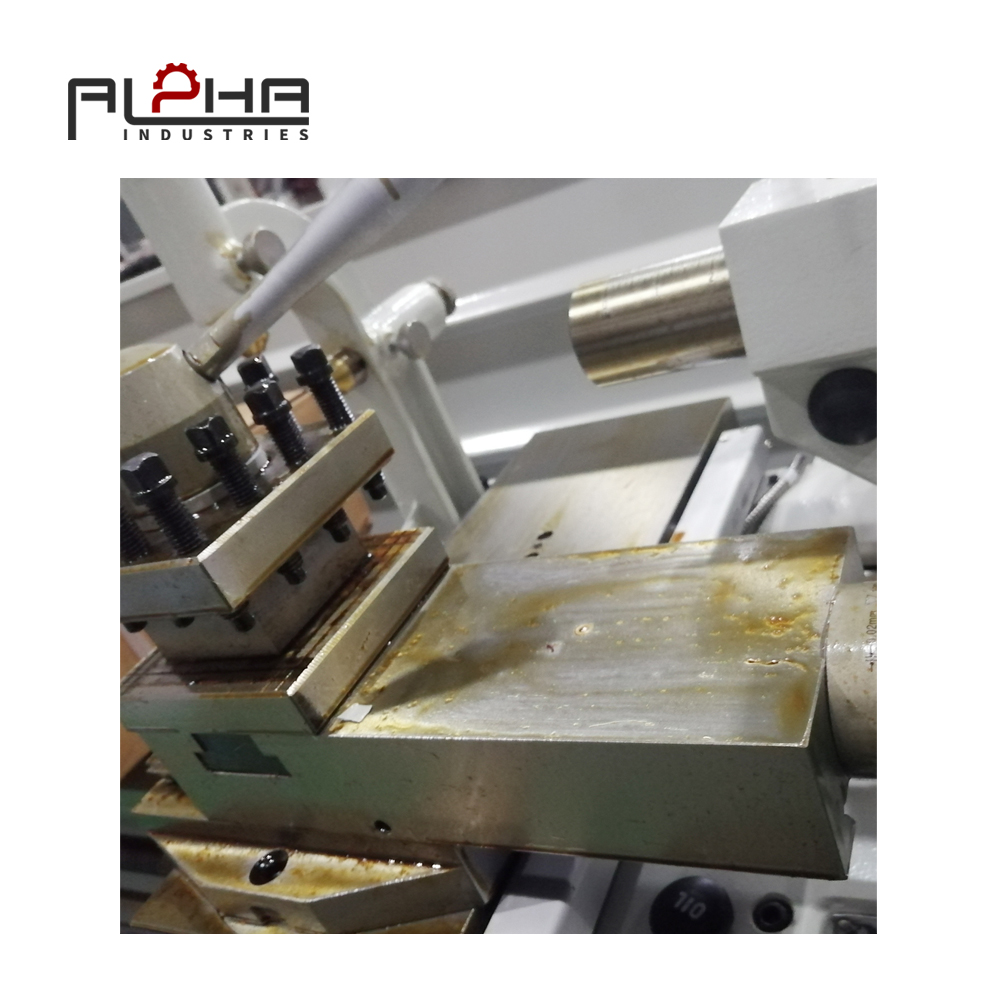

3. Tool Post and Slideway Accuracy

Alpha’s tool post system features quick-indexing turrets for faster tool changes, reducing non-cutting time. The hardened and ground slideways ensure smooth linear motion and precise alignment between the carriage and spindle centerline. For automated versions, the ball screw and servo feed drive combination enhances repeatability and allows micro-step feed control, ensuring consistent surface quality across every workpiece.

Advanced Control and Automation Features

Modern lathe machines from Alpha incorporate intelligent control systems that elevate performance and user experience:

-

Servo-Driven Feeds for smooth, programmable movement

-

Digital Positioning Displays (DRO) for micron-level accuracy

-

Smart Lubrication Systems that maintain consistent friction control

-

Optional CNC Packages for automated cycle operations and contour turning

Surface Finish and Tolerance Control

High-precision turning is not only about dimensions but also about surface integrity. Alpha’s lathe machines achieve surface roughness as low as Ra 0.8 μm, thanks to the optimized cutting path and stable feed mechanism. The combination of precision chuck alignment, spindle speed stability, and tool geometry accuracy ensures mirror-like finishes on cylindrical, conical, or threaded parts.

Applications of Alpha Precision Lathe Machines

Alpha’s precision lathes are widely applied in:

-

Automotive shaft and gear manufacturing

-

Aerospace component machining

-

Hydraulic cylinder and valve body turning

-

Tool and mold base processing

-

Custom machining workshops requiring tight tolerances

Each application benefits from Alpha’s proven balance between accuracy, efficiency, and reliability, making our lathes the ideal solution for high-end metal fabrication industries.

Maintenance and Longevity

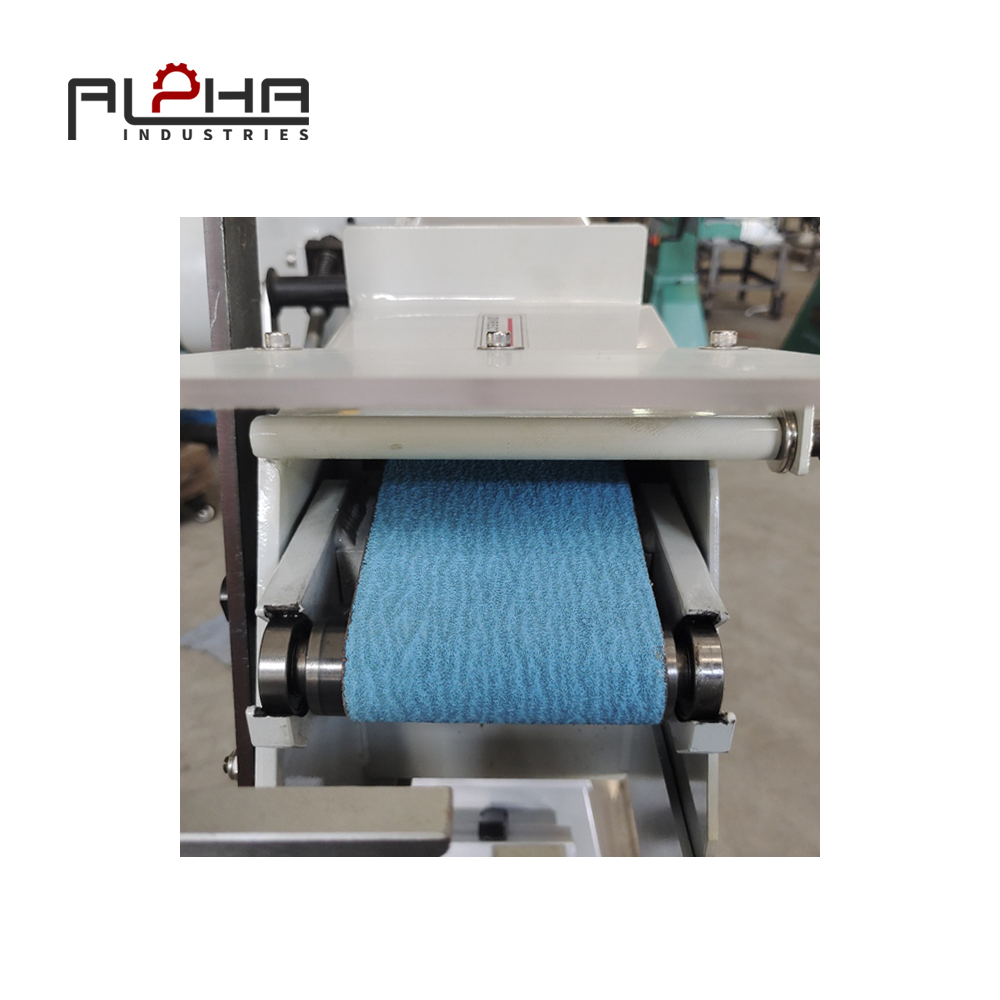

To maintain consistent precision, Alpha designs its lathe machines for easy maintenance and extended lifespan:

-

Lubrication points are centralized for quick service.

-

Electrical cabinets feature modular layout for easy troubleshooting.

-

Machine slides and screws are protected with covers to prevent contamination.

-

Real-time temperature compensation ensures precision stability under long runs.

These elements together reduce downtime and ensure long-term accuracy retention, critical for industrial production lines.

Why Choose Alpha Lathe Machine

-

High Rigidity, Low Vibration Design

-

Ultra-Precision Spindle with Long Bearing Life

-

Smart Control and Feed Systems

-

Superior Surface Finish and Accuracy

-

Customizable Options for Various Industries

-

Global Service Network and Fast Delivery

At Alpha, each lathe is the result of meticulous engineering and precision manufacturing, ensuring top-tier performance for every operator.

FAQ Section

Q1: What determines the accuracy of a lathe machine?

A1: The accuracy depends on spindle runout, bed rigidity, slideway alignment, and tool clamping precision—all optimized in Alpha’s design.

Q2: How does Alpha ensure vibration-free operation?

A2: By using a monoblock cast iron bed with ribbed reinforcement and dynamic balancing for all rotating parts.

Q3: What materials can be processed on Alpha’s lathe machine?

A3: Steel, aluminum, copper, brass, titanium, and various alloys can be precisely turned.

Q4: What is the standard surface roughness achievable?

A4: Alpha’s precision lathes achieve up to Ra 0.8 μm, depending on cutting parameters and tooling.

Q5: Does Alpha provide customized lathe solutions?

A5: Yes, Alpha offers tailored machine configurations for different industries and production scales.

Conclusion: Redefining Precision Metal Turning

The Alpha Precision Lathe Machine represents the next generation of metal turning technology—delivering accuracy, efficiency, and versatility that redefine machining performance. From small workshops to industrial production lines, Alpha provides reliable solutions for any precision turning challenge.

Experience the difference in precision.

Explore more at Alpha’s Official Website.