Introduction – Precision Engineering Behind Every Turn

A lathe machine is one of the most fundamental and versatile tools in modern metalworking. From producing cylindrical components to complex geometric profiles, its performance depends heavily on spindle precision—the mechanical heart that defines rotational accuracy, vibration control, and machining stability.

At ALPHA, we focus on one of the most critical aspects of a lathe machine: the high-precision spindle system, engineered to ensure flawless turning accuracy and surface finish even under continuous heavy-duty operation.

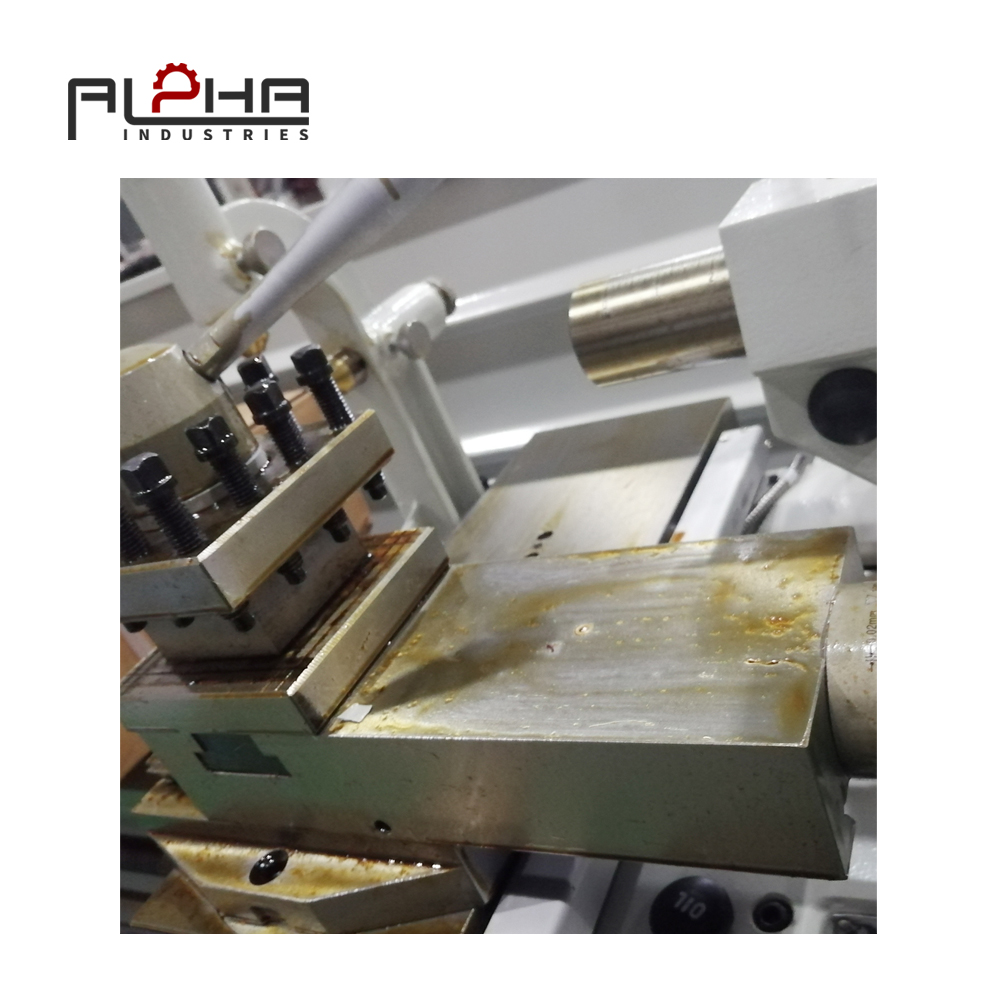

Core Structure of Lathe Spindle System

The spindle system in a lathe determines the overall performance of metal cutting. ALPHA’s lathes adopt high-rigidity spindle assemblies supported by double-row precision bearings, ensuring minimal runout and superior rotational balance.

Key Structural Features:

-

Dynamic Balancing Design: Reduces vibration at high spindle speeds.

-

High-Tensile Spindle Housing: Provides structural stability under heavy cutting loads.

-

Preloaded Angular Contact Bearings: Enhances rotational stiffness and repeatability.

-

Lubrication and Cooling Integration: Maintains consistent temperature during prolonged operations.

This robust design ensures smooth torque transmission and exceptional turning precision across various metals including stainless steel, carbon steel, aluminum, and titanium alloys.

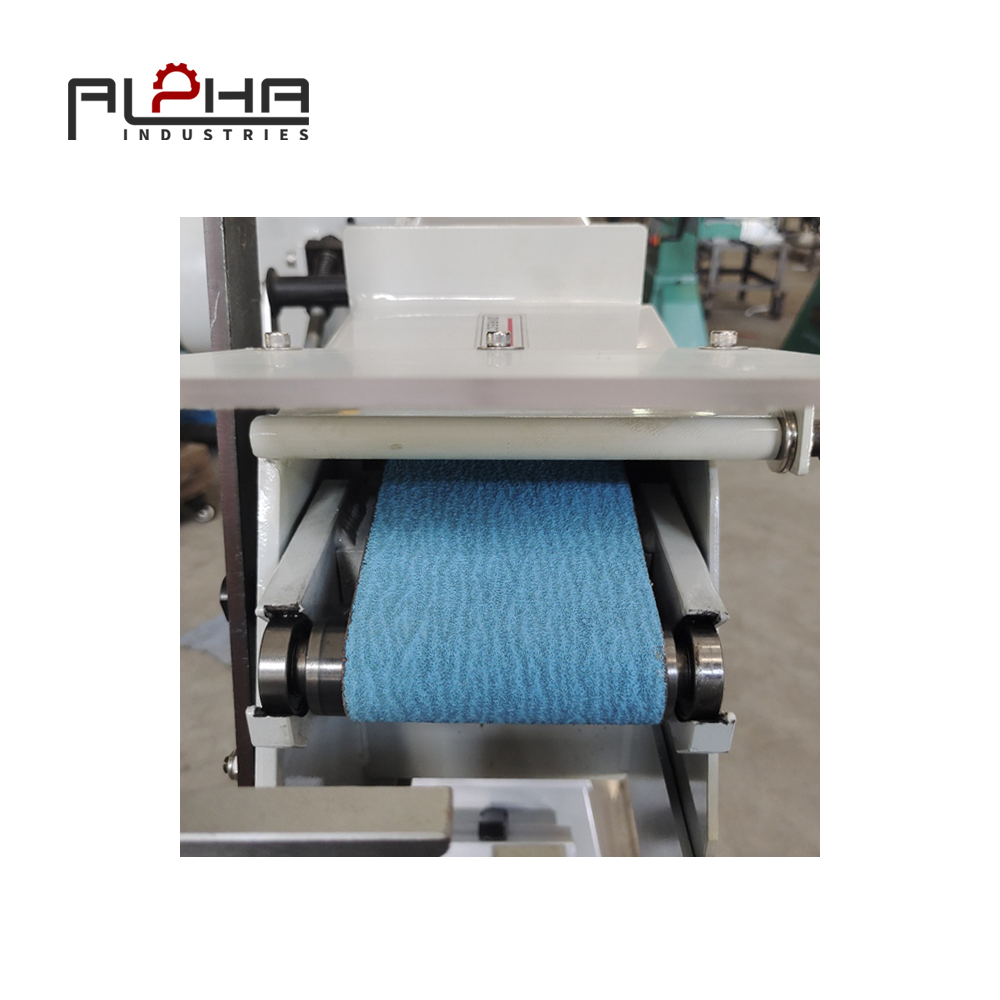

Thermal Stability and Spindle Cooling Control

One of the main challenges in high-speed turning is thermal deformation. ALPHA integrates an oil-air lubrication and spindle cooling system to manage temperature gradients effectively.

This system:

-

Maintains consistent thermal equilibrium during extended runs.

-

Prevents dimensional errors caused by spindle heat expansion.

-

Extends bearing life and minimizes maintenance frequency.

By controlling thermal behavior, ALPHA’s lathe spindle achieves sustained micron-level machining accuracy, essential for industries such as automotive, aerospace, and precision tooling.

Vibration Suppression and Surface Finish Quality

Surface finish quality depends on spindle rigidity and vibration control. ALPHA lathes incorporate vibration-damping materials and smart balance calibration technology.

-

Vibration Analysis Sensors detect real-time imbalance.

-

Dynamic Compensation Algorithms adjust cutting feed to maintain surface integrity.

-

The result is a consistent Ra 0.8 μm surface finish even at high cutting speeds.

This precision advantage enhances tool life, reduces scrap rate, and ensures the highest dimensional conformity in mass production.

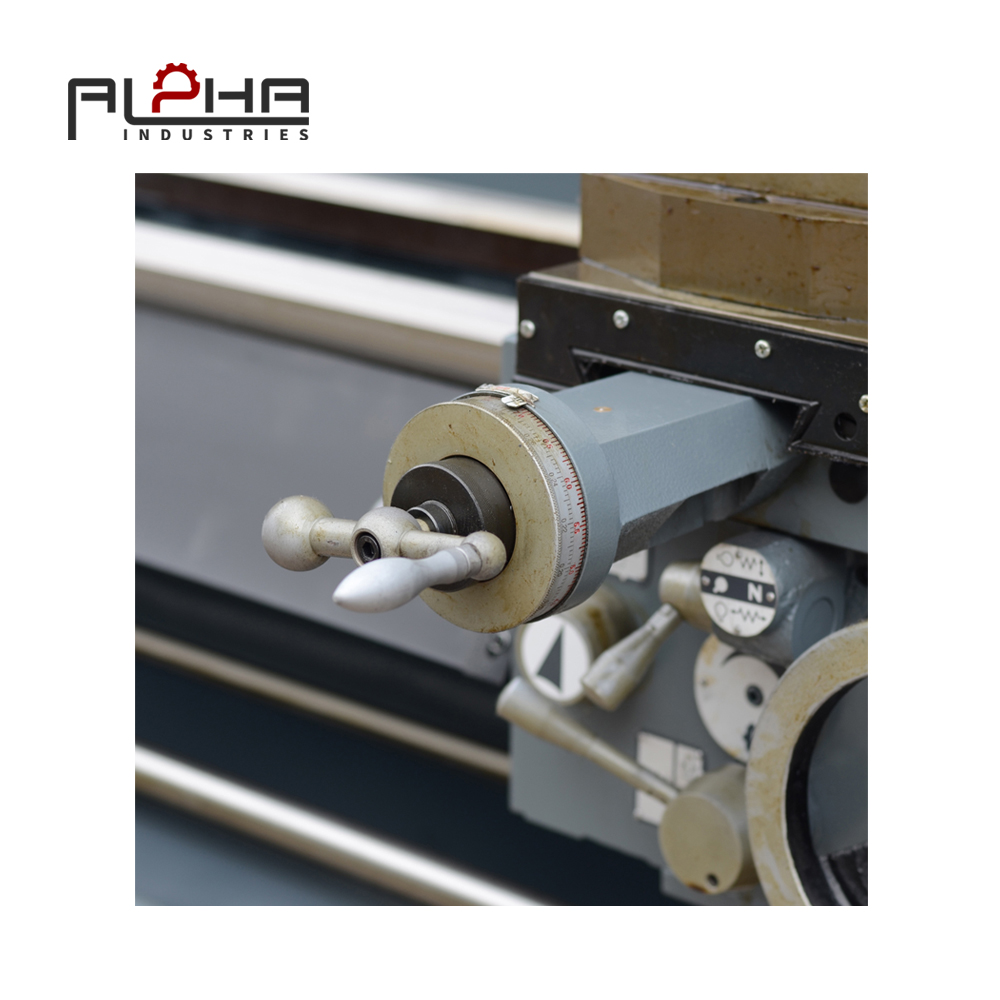

Drive Motor and Torque Transmission

The spindle drive system adopts servo-controlled vector motors, ensuring constant torque across the speed range.

Advantages:

-

High Torque at Low Speed: Ideal for roughing and threading operations.

-

Constant Speed Regulation: Maintains uniform chip removal.

-

Reduced Backlash: Ensures tight tolerance during contour turning.

This power efficiency enables continuous production cycles without compromising accuracy or surface quality.

Applications of ALPHA Lathe Machines

ALPHA lathes are widely applied in:

-

Automotive Component Machining – precision shafts, gears, and hubs.

-

Aerospace Manufacturing – turbine parts and engine components.

-

Mold & Tool Industry – precision dies and fixture components.

-

General Metal Fabrication – production of custom shafts, bushings, and flanges.

Each application benefits from the rigid structure, precise spindle design, and intelligent control system that define ALPHA’s engineering philosophy.

Maintenance and Service Life Optimization

Proper spindle maintenance is essential for long-term performance. ALPHA recommends:

-

Regular lubrication checks every 500 hours.

-

Vibration analysis every 1000 hours.

-

Spindle alignment inspection biannually.

With these measures, the spindle lifespan can exceed 20,000 operational hours, maintaining precision without performance degradation.

Advantages of Choosing ALPHA Lathe Machines

-

Superior Spindle Precision for micron-level tolerance.

-

Thermal Control System to maintain dimensional accuracy.

-

High-Torque Motor Drive for versatile machining.

-

Durable Construction ensuring stability and longevity.

-

Smart Monitoring System for predictive maintenance.

Each lathe embodies ALPHA’s commitment to innovation, reliability, and global manufacturing excellence.

FAQ – Technical Insights on Lathe Machines

Q1: What determines the accuracy of a lathe machine?

A1: The accuracy primarily depends on the spindle alignment, bearing precision, and thermal stability of the system.

Q2: How does spindle vibration affect surface finish?

A2: Vibration causes tool chatter and micro-deflection, leading to poor surface roughness and dimensional deviation.

Q3: What is the ideal spindle speed for precision turning?

A3: The ideal speed varies with material hardness and tool geometry, but ALPHA lathes maintain constant torque across 150–3500 RPM ranges.

Q4: How can I improve my lathe’s thermal performance?

A4: Integrate spindle cooling systems, ensure proper lubrication, and maintain ambient temperature control in the workshop.

Q5: What industries benefit most from precision lathes?

A5: Automotive, aerospace, and mold-making sectors rely heavily on precision lathes for consistent and accurate part production.

Conclusion – Redefining Turning Precision

ALPHA’s lathe machines combine mechanical excellence and digital intelligence to achieve world-class turning precision. By focusing on spindle innovation, thermal management, and AEO-enabled monitoring, we ensure that every cut, every rotation, and every component meets the highest industrial standards.

👉 Explore more precision machining solutions at ALPHA Official Website