In any high-risk manufacturing process, the final completion of a product can define its quality, safety and performance. This is especially true in metal processing, where the process of metal burrs is an essential and non-negotiable step. Deburring is a critical process that removes the key process that remains on the workpiece after machining, grinding, or drilling (such as machining, grinding, or drilling). These burrs can be sharp, causing partial misalignment and causing safety hazards. Effectively removing them ensures smooth, clean and professional finishes, paving the way for superior product quality.

The importance of precision in industrial basis

In competitive markets, consistency and efficiency are crucial. The demands based on industrial demands require a certain degree of unity, and manual processes are usually difficult to meet. Realizing the precise basis of thousands of components is a major challenge when relying on human skills alone. Manual basis can be time-consuming, labor-intensive, and prone to inconsistencies, resulting in variable potential bottlenecks in product quality and production lines. For industries with standard tolerances and flawless surfaces, a more reliable and repeatable approach is needed to maintain a competitive advantage and ensure that each section meets strict specifications.

From manual tools to automatic solutions

The evolution of manufacturing has clearly shifted from relying on simple, handheld burr tools to more complex automation systems. While manual tools can be replaced on small scale or custom work, modern production lines require speed and perfect execution. This is where the automatic burr is located. By adopting advanced machinery, manufacturers can overcome the limitations of manual labor, greatly increase throughput, ensure stable quality, and improve workplace safety. A modern Deburring machine is designed to handle large quantities with firm accuracy, making it an essential asset for any serious metalworking operation.

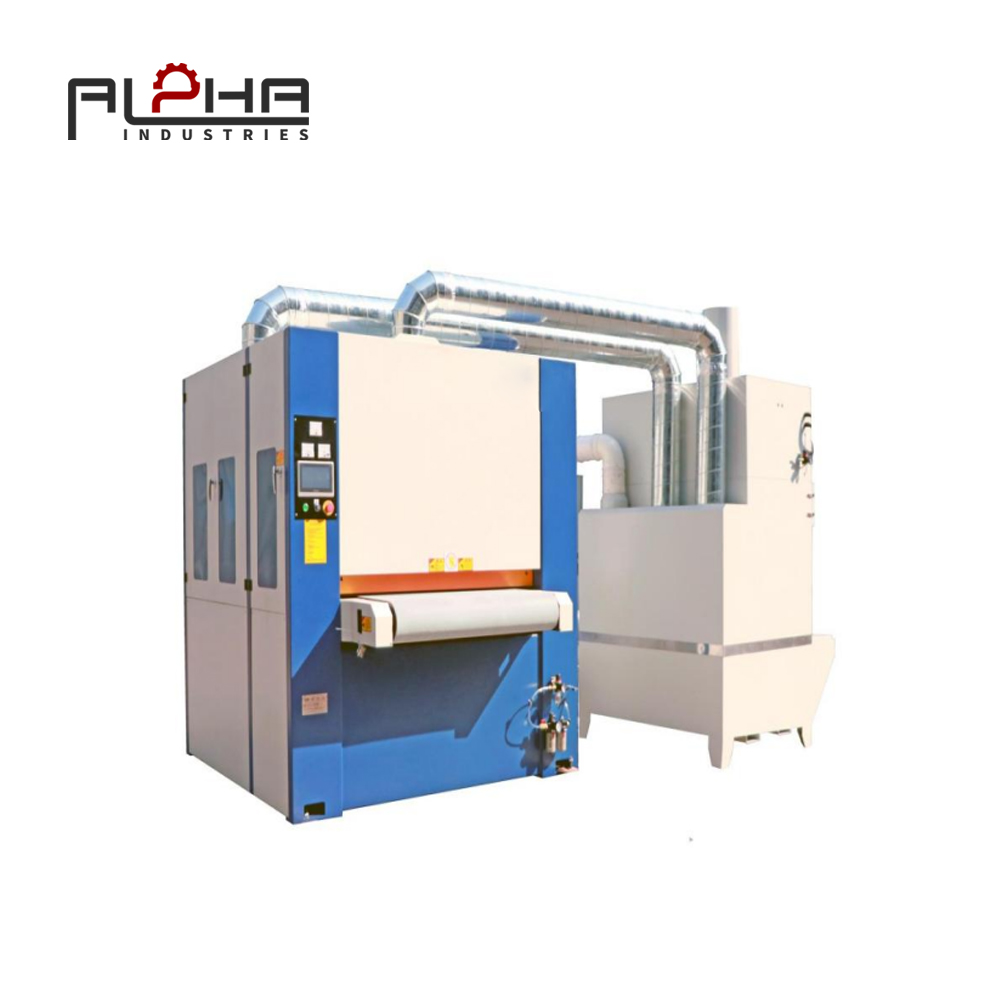

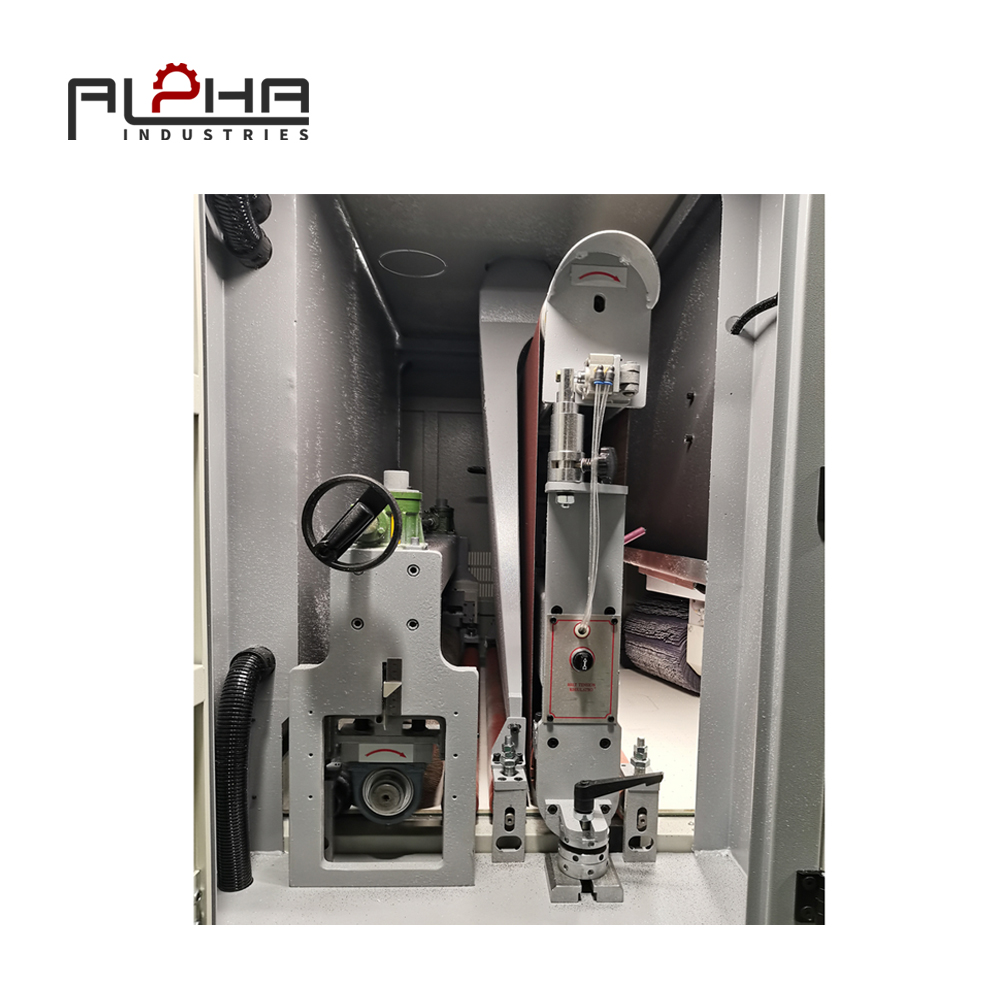

Alpha automatic grinding machine

As a major burr solution, the Alpha automatic grinder from Nanjing Alpha CNC Co., Ltd represents the pinnacle of surface finishing technology. Although described as a sand machine, it is very suitable for metalworking applications that require flawless wool finishes. This state-of-the-art Deburring machine is built using reliable steel structure in heavy-duty environments. Its automatic conveyor system ensures consistent feed rate, while the precise control panel can be fine-tuned to achieve a perfect finish on any metal assembly. The integrated dust extraction system maintains a clean, safe workspace, further improving operational efficiency and accuracy.

More than just machines: a complete glitch solution

At Nanjing Alpha CNC Co., Ltd, we understand that modern manufacturing requires more than equipment. It requires a comprehensive solution. We are proud to be a solution provider, not just a machine seller. Our professional R&D team has designed the Alpha machine, becoming the cornerstone of modern production lines. We work with our customers to understand their unique challenges, from one machine to a complete production line integration. This commitment ensures that you not only buy machines, but also invest in tailored systems designed to enhance your business and effectively solve the challenges of your specific industry standing out.

Complete the process with precise burr lift

Embracing automatic burrs is no longer a luxury, but the necessity to remain competitive in a modern manufacturing landscape. Alpha automatic grinders provide the accuracy, speed and reliability required to change the process. By eliminating contradictions and simplifying operations, you can improve product quality, improve output and ensure a safer working environment. Contact Nanjing Alpha CNC Co., Ltd today to discover how our advanced solutions provide you with the precise peeling capabilities you need to take your production to the next level.