Lathe Machine Rigidity – The Foundation of Precision Turning

In metalworking industries, the lathe machine is one of the most widely used and essential pieces of equipment. Whether producing shafts, flanges, rollers, or mechanical components, the final machining quality depends heavily on one critical factor:

The rigidity and structural stability of the lathe machine

This article focuses on a single professional topic:

Why lathe machine rigidity is the core element that determines turning accuracy and machining performance

By understanding this point deeply, manufacturers and operators can choose better machines, improve processing quality, and reduce long-term production costs.

What Is Lathe Machine Rigidity and Why Does It Matter?

Rigidity refers to the ability of a lathe machine to resist deformation when subjected to cutting forces. During turning operations, the cutting tool applies significant pressure to the workpiece. If the machine structure is not rigid enough, it will lead to:

-

Vibration and chatter

-

Dimensional errors

-

Poor surface finish

-

Shorter tool life

-

Unstable production quality

Therefore, rigidity is not just a technical indicator – it is the foundation of every accurate turning operation.

A high-rigidity lathe machine allows:

-

Heavier cutting loads

-

Higher efficiency

-

Better precision

-

Longer machine life

For industries that require reliable machining results, rigidity is the first element to evaluate when selecting a lathe.

Core Structural Elements That Determine Lathe Machine Rigidity

The overall rigidity of a lathe machine is not decided by a single part. It is the result of multiple structural components working together.

1. Lathe Bed – The Backbone of the Machine

The lathe bed is the main supporting structure of the entire machine. All other parts – headstock, carriage, tailstock – are mounted on it.

A high-quality lathe bed should have:

-

Heavy cast iron construction

-

Reinforced rib design

-

Precision-ground guideways

-

Strong vibration absorption

If the lathe bed lacks strength, no amount of adjustment can compensate for poor machining stability.

That is why industrial-grade lathe machines always use one-piece casting beds with optimized structural design.

2. Headstock and Spindle System

The headstock houses the spindle, gears, and transmission system. Its rigidity directly affects:

-

Rotational stability

-

Cutting force resistance

-

Concentricity of the workpiece

A weak headstock structure will cause:

-

Spindle vibration

-

Inaccurate turning diameter

-

Poor surface roughness

High-rigidity lathe machines use:

-

Precision bearings

-

Strong spindle shafts

-

Heavy-duty gear systems

These features ensure smooth and stable power transmission even under heavy cutting conditions.

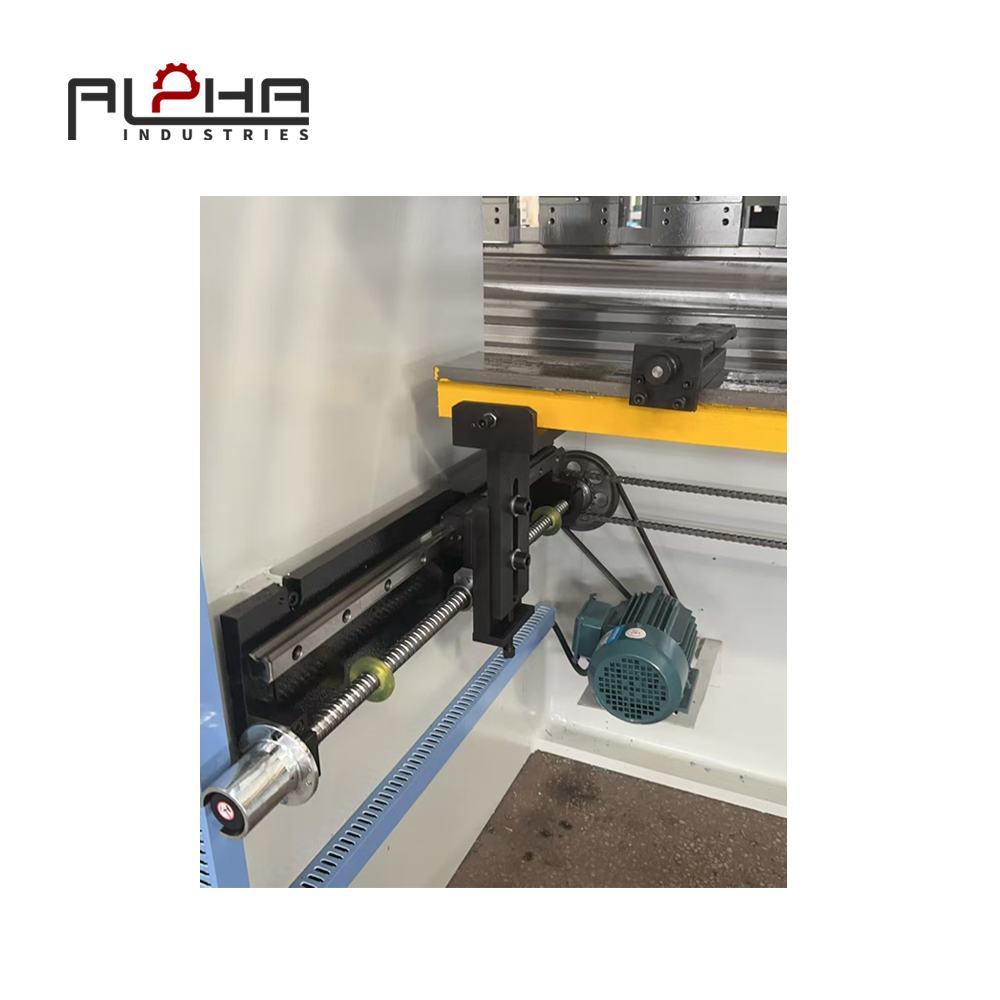

3. Carriage and Tool Post Stability

During turning, the carriage moves along the bed while holding the cutting tool. Any looseness or deformation in this system will immediately reduce accuracy.

Key requirements include:

-

Solid carriage casting

-

Tight guideway fitting

-

Reliable locking mechanisms

-

Strong tool post design

A stable carriage system ensures:

-

Consistent cutting depth

-

Smooth tool movement

-

Accurate dimensional control

4. Tailstock Strength and Alignment

For long workpieces, the tailstock provides essential support. If the tailstock lacks rigidity or alignment accuracy, it can lead to:

-

Workpiece bending

-

Taper errors

-

Vibrations

High-quality lathe machines are designed with:

-

Heavy-duty tailstock bodies

-

Precision alignment systems

-

Strong clamping force

How Poor Rigidity Affects Turning Quality

When a lathe machine does not have sufficient rigidity, many machining problems occur:

| Problem | Cause |

|---|---|

| Chatter marks | Structural vibration |

| Size variation | Machine deformation |

| Poor finish | Unstable cutting |

| Short tool life | Excessive movement |

| Low efficiency | Need for light cutting |

These issues not only reduce product quality but also increase:

-

Production time

-

Tool consumption

-

Rework rates

-

Manufacturing costs

Therefore, investing in a rigid lathe machine is actually a long-term cost-saving decision.

Operational Factors That Influence Rigidity Performance

Even with a high-rigidity lathe machine, improper operation can still reduce performance.

Correct Cutting Parameters

To fully utilize machine rigidity:

-

Cutting speed must match material

-

Feed rate should be appropriate

-

Depth of cut should be reasonable

Overloading the machine beyond its design capacity will always reduce precision.

Proper Workpiece Clamping

Weak or incorrect clamping is one of the most common causes of vibration.

Operators should:

-

Use suitable chucks

-

Apply correct jaw pressure

-

Support long shafts with steady rests

-

Ensure firm tailstock engagement

Tool Selection and Setup

High-quality cutting tools with proper geometry help reduce cutting resistance, which in turn improves overall rigidity performance.

Maintenance – Protecting Lathe Machine Rigidity

Rigidity is not only a design feature – it must be maintained over time.

Lack of maintenance can gradually reduce machine stability through:

-

Worn guideways

-

Loose bolts

-

Bearing wear

-

Insufficient lubrication

Recommended Maintenance Actions

-

Regular guideway lubrication

-

Checking spindle bearings

-

Adjusting gibs

-

Tightening structural bolts

-

Cleaning chips and coolant

A well-maintained lathe machine keeps its rigidity and accuracy for many years.

How ALPHA Ensures High-Rigidity Lathe Machines

At ALPHA, rigidity is considered the first design principle for every lathe machine.

Our machines feature:

-

Heavy-duty cast iron beds

-

Reinforced structural ribs

-

Precision-ground guideways

-

High-stability headstock systems

-

Reliable mechanical transmission

-

Strict assembly and testing standards

These advantages provide customers with:

-

Stable machining performance

-

Higher precision

-

Longer service life

-

Lower maintenance cost

Whether for small workshops or large factories, ALPHA lathe machines deliver dependable turning solutions.

Industries That Rely on Rigid Lathe Machines

High-rigidity lathe machines are essential in:

-

Mechanical manufacturing

-

Automotive parts

-

Energy equipment

-

Agricultural machinery

-

Pump and valve production

-

Mining and heavy industry

Anywhere that requires accurate and stable turning, machine rigidity is the key to success.

Frequently Asked Questions

Q1: What is the most important factor in a lathe machine?

A: Rigidity is the most important factor, because it directly affects machining accuracy, surface finish, and stability.

Q2: How does rigidity influence turning accuracy?

A: Higher rigidity reduces vibration and deformation, allowing the lathe machine to maintain consistent dimensions and better surface quality.

Q3: Which part of a lathe machine provides the main rigidity?

A: The lathe bed is the main source of rigidity, followed by the headstock, carriage, and tailstock.

Q4: Can maintenance affect machine rigidity?

A: Yes. Poor lubrication, loose components, and worn guideways can significantly reduce rigidity over time.

Q5: How to choose a rigid lathe machine?

A: Look for heavy cast iron construction, reinforced bed design, precision spindles, and strong mechanical structure.

Conclusion

For any lathe machine, rigidity is the true foundation of performance. No matter how skilled the operator is or how advanced the tooling may be, machining accuracy ultimately depends on the structural strength of the machine itself.

A rigid lathe machine provides:

-

Better precision

-

Higher efficiency

-

Longer tool life

-

More reliable production

At ALPHA, we focus on designing and manufacturing lathe machines with maximum rigidity and stability to help customers achieve superior turning results.

If you are looking for a professional and reliable lathe machine supplier, or need technical advice on selecting the right model, please feel free to [contact us].

Internal Links

-

Learn more about our machines: https://alpha-cnc.com/

-

Get professional support: contact us