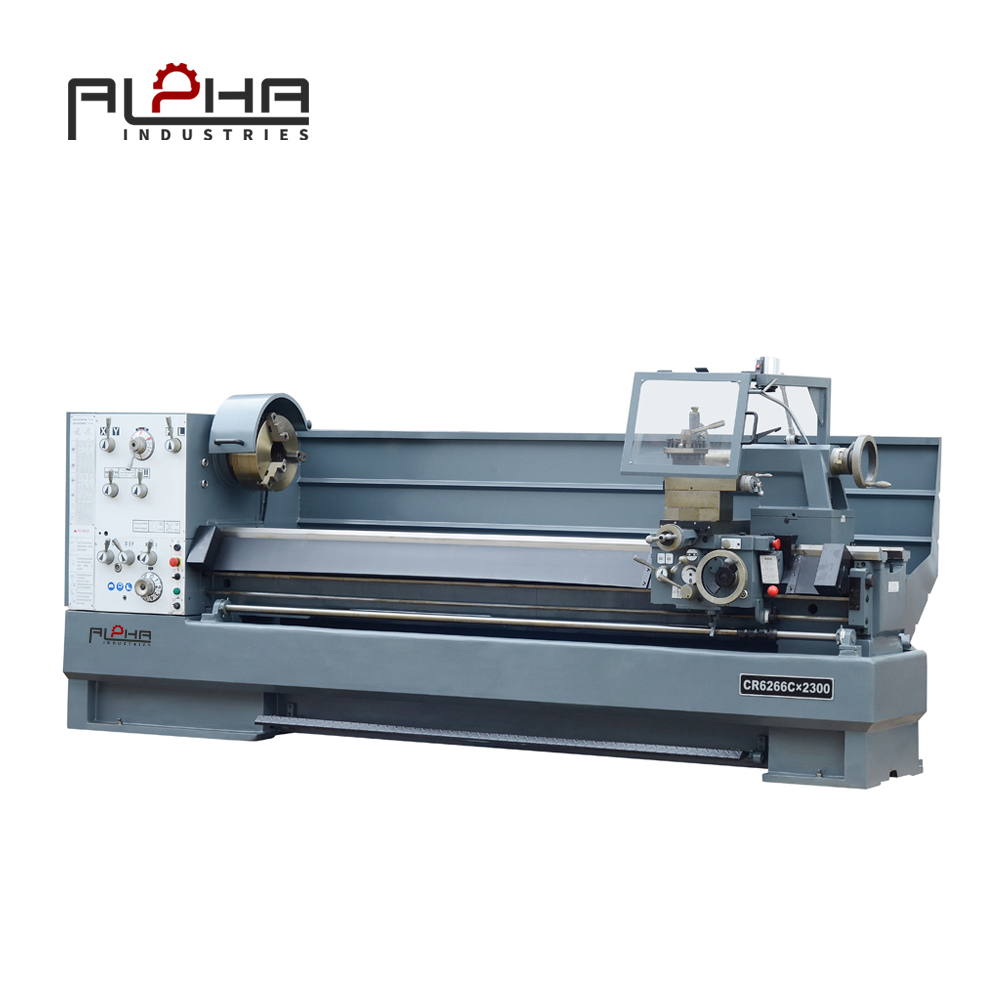

Overview: High-Precision Lathe Turning

Lathe machines are essential tools for industrial metalworking, used to produce cylindrical and complex rotational parts. Alpha lathes combine high rigidity, precision spindle systems, and advanced CNC controls to achieve:

-

Ultra-precise diameter tolerances

-

Smooth surface finish with minimal post-processing

-

High-efficiency batch production

-

Complex part geometry with repeatable accuracy

They are widely applied in automotive, aerospace, mold manufacturing, energy, and machinery components.

Core Challenge: Maintaining Precision in High-Volume Turning

High-volume turning of metals presents several challenges:

-

Tool deflection under heavy cuts

-

Thermal expansion affecting dimensional accuracy

-

Material inconsistencies causing uneven surface finish

-

High spindle loads impacting speed and repeatability

Alpha lathes overcome these challenges with rigid cast-iron frames, precision-ground beds, and high-speed, low-runout spindles, ensuring consistent results across long production runs.

High-Rigidity Frame and Precision Spindle

Alpha lathes feature:

-

Box-type cast-iron frames for vibration damping

-

Linear guideways for precise carriage movement

-

High-speed spindles with minimal runout

These design elements allow:

-

Heavy-duty cutting without deflection

-

Superior surface finish (Ra < 0.8 µm)

-

Longer tool life and lower maintenance

CNC Integration for Advanced Lathe Operations

Alpha CNC lathes support:

-

Multi-axis turning for complex parts

-

Automated threading, grooving, and taper cutting

-

High-resolution linear encoders for precise positioning

-

Tool path optimization for reduced cycle time

This allows unattended batch production while maintaining tight dimensional tolerances.

Thermal Control and Tool Management

To maintain precision, Alpha lathes include:

-

Spindle and bed thermal compensation

-

Coolant-through tooling for consistent cutting

-

Dynamic feed adjustment to prevent chatter

These systems minimize thermal distortion, tool wear, and dimensional errors, essential for high-volume production.

Applications in Industrial Manufacturing

Alpha lathes are used in:

-

Automotive: shafts, engine components, wheel hubs

-

Aerospace: landing gear shafts, structural rods

-

Industrial machinery: molds, rollers, hydraulic cylinders

-

Energy sector: turbine shafts, pump components

-

Precision tooling: drill sleeves, bearing housings

They provide high precision, consistent quality, and high throughput.

Advantages Over Conventional Lathes

| Feature | Alpha Lathe | Conventional Lathe |

|---|---|---|

| Precision | ±0.01 mm | ±0.1 mm or more |

| Automation | CNC multi-axis | Manual or limited CNC |

| Surface Finish | Smooth, low Ra | Often requires rework |

| Productivity | High-volume batch | Slower, manual operations |

| Tool Life | Extended due to rigid frame | Shorter under heavy cuts |

Alpha lathes improve productivity, reduce rework, and enhance operational efficiency.

Alpha Quality Control

Each Alpha lathe undergoes:

-

Laser straightness testing of bed and carriage

-

Spindle runout verification

-

Thermal compensation calibration

-

Trial cutting for repeatability

Ensuring every machine meets industrial standards for precision and reliability.

FAQ

Q1: What types of workpieces can be processed on a lathe?

Cylindrical parts, shafts, hubs, rollers, threaded components, and precision bushings.

Q2: How does Alpha lathe maintain high precision under heavy load?

Through a high-rigidity frame, linear guideways, thermal compensation, and low-runout spindles.

Q3: Can Alpha lathes perform automated batch production?

Yes, CNC integration allows continuous, unattended operation.

Q4: What industries benefit most from Alpha lathes?

Automotive, aerospace, industrial machinery, energy, and precision tooling.

Q5: How does CNC integration improve lathe performance?

It enables multi-axis operations, precise tool paths, reduced cycle times, and high repeatability.

For high-precision, high-efficiency metal turning, Alpha lathes provide the ideal solution.

👉 Explore more Alpha Metal Processing Equipment:

-

CNC Lathe Slant – High-precision turning solution

-

Vertical Machining Center – Multi-axis milling system

-

Press Brake Machine – Long-sheet precision bending

-

Drilling & Milling Machine – Dual-function machining

-

Surface Grinder – Ultra-fine finishing accuracy